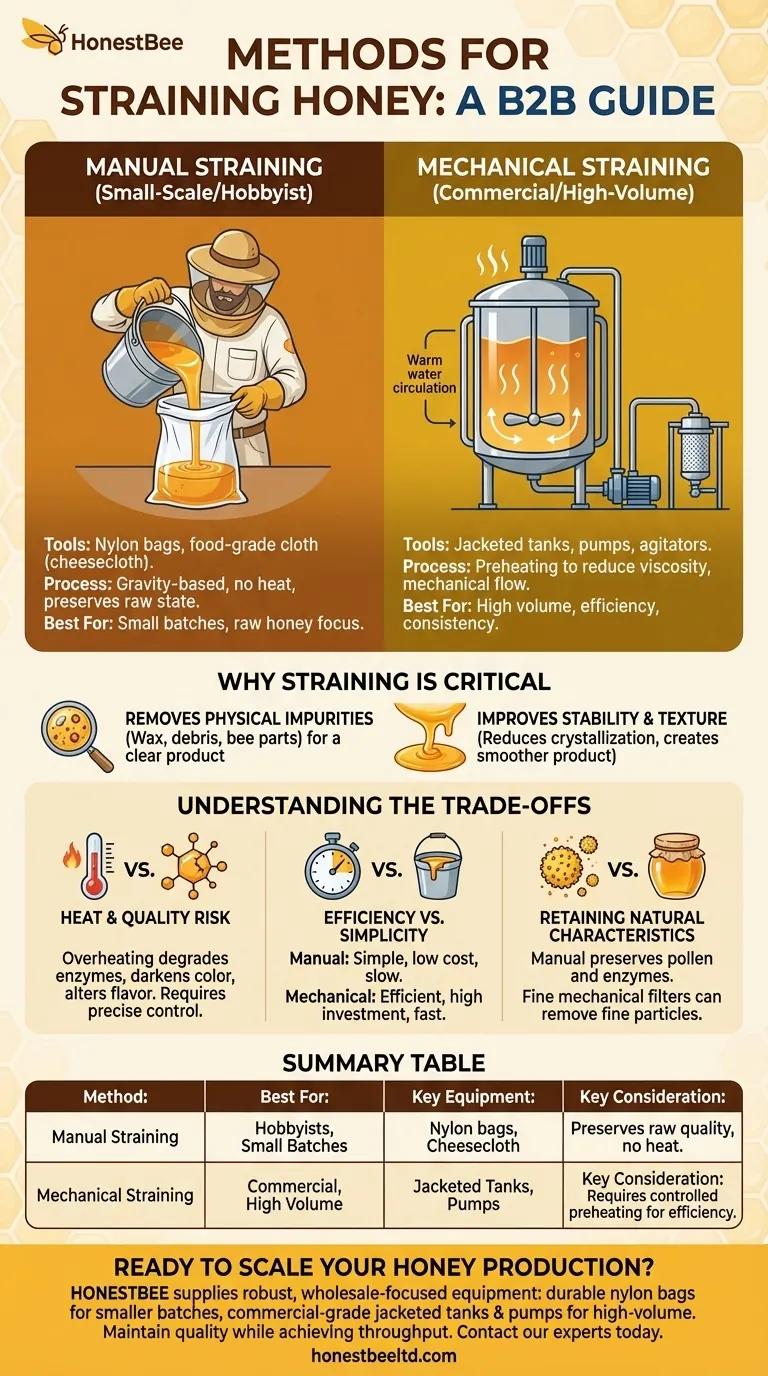

At its core, honey is strained using two primary approaches. For small-scale or hobbyist operations, straining is typically a manual process using simple tools like cloth or nylon bags. For larger commercial operations, straining is a mechanical process that often involves preheating the honey in specialized tanks to improve flow and efficiency.

The goal of straining is to remove impurities like wax and debris while preserving the honey's natural quality. The right method is determined entirely by the scale of your operation and your need for efficiency versus simplicity.

Why Straining is a Critical Step

Straining is an essential part of honey processing that directly impacts the final product's quality, appearance, and shelf life. It is not the same as filtering, which often removes fine particles like pollen.

Removing Physical Impurities

The primary purpose of straining is to remove visible debris left over from the extraction process. This includes bits of beeswax, wood from the frames, and parts of bees.

Removing these impurities creates a clearer, more visually appealing product that consumers expect.

Improving Stability and Texture

Leaving wax cappings and other particles in the honey can act as nucleation sites, accelerating crystallization.

By straining the honey, you create a smoother final product and can help extend the time it remains in a liquid state on the shelf.

Manual Straining: The Small-Scale Method

For hobbyists or beekeepers with only a few hives, manual straining is the most practical and cost-effective method. It relies on gravity and simple tools.

The Tools and Materials

The most common tools are nylon straining bags or simple pieces of food-grade cloth (like cheesecloth) fitted over a bucket or storage tank.

These materials are inexpensive, reusable, and easy to clean, making them ideal for small batches.

The Process

The process is straightforward: extracted honey is simply poured through the strainer. Gravity pulls the liquid honey through the mesh, leaving the larger solids like wax and debris behind.

This method requires no electricity and preserves the honey in its most raw state, as no heat is applied.

Mechanical Straining: The Commercial Approach

For commercial producers, manual straining is too slow and labor-intensive. Mechanical systems are designed for high-volume efficiency.

The Role of Preheating

Cold honey is highly viscous and flows very slowly. To speed up the process, large-scale operations preheat the honey.

Warming the honey lowers its viscosity, allowing it to pass through strainers much more quickly and easily.

Specialized Equipment

This process typically uses a jacketed tank. This is a tank with a double wall where warm water can circulate, gently heating the honey without scorching it.

These tanks are often fitted with a stirrer or agitator to ensure the heat is distributed evenly throughout the honey, preventing hot spots that could damage its delicate enzymes and flavor. From there, the warm honey is pumped through a straining system.

Understanding the Trade-offs

Choosing a method involves balancing efficiency, cost, and the potential impact on honey quality.

Heat and Honey Quality

The biggest risk in mechanical straining is overheating. Applying too much heat can degrade the natural enzymes, darken the honey's color, and alter its flavor profile.

Properly designed commercial systems use precise temperature controls to warm the honey just enough to reduce viscosity without causing damage.

Efficiency vs. Simplicity

Manual straining is simple but slow. It is perfectly suited for a few gallons but becomes a significant bottleneck for hundreds or thousands.

Mechanical straining is highly efficient but requires a substantial investment in equipment like heated tanks, pumps, and pipes.

Retaining Natural Characteristics

Manual, unheated straining is the best way to preserve all the natural characteristics of raw honey, including its pollen content. While not all consumers are aware, some seek out honey with pollen for its perceived health benefits.

Very fine mechanical filters, especially when combined with heat, can sometimes remove more of these fine particles than a simple cloth strainer.

Making the Right Choice for Your Goal

Your decision should be guided by your production volume and your philosophy on processing.

- If your primary focus is small-batch, raw honey: Stick with manual straining using nylon or cloth filters to preserve the honey's natural state with minimal investment.

- If your primary focus is commercial-scale efficiency and consistency: Invest in a mechanical system with carefully controlled preheating to process large volumes quickly and reliably.

Understanding these methods allows you to process your honey in a way that aligns perfectly with your goals and resources.

Summary Table:

| Method | Best For | Key Equipment | Key Consideration |

|---|---|---|---|

| Manual Straining | Hobbyists, Small Batches | Nylon bags, Cheesecloth | Preserves raw quality, no heat |

| Mechanical Straining | Commercial, High Volume | Jacketed Tanks, Pumps | Requires controlled preheating for efficiency |

Ready to Scale Your Honey Production?

As a commercial apiary or beekeeping equipment distributor, choosing the right straining method is critical for your operation's efficiency and product quality. HONESTBEE supplies the robust, wholesale-focused equipment you need—from durable nylon straining bags for smaller batches to commercial-grade jacketed tanks and pumps for high-volume processing.

We help you maintain honey quality while achieving the throughput your business demands. Contact our experts today to discuss the best straining solution for your specific needs.

Visual Guide

Related Products

- Stainless Steel Triangle Support Honey Strainer and Filters

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- Professional 4 Frame Self Reversing Electric Honey Extractor for Beekeeping

People Also Ask

- Should honey be filtered or unfiltered? Maximize Health Benefits with Raw Honey

- What are the benefits of using a honey strainer for beekeepers? Achieve Clean, High-Quality Honey Efficiently

- What is the function of honey sieves, strainers, and filters in processing? Master the 3 Stages of Honey Purity

- What is the easiest way to strain honey? A Simple Guide for Hobbyist Beekeepers

- Why is filtering important in honey processing, and what equipment is used? A Guide to Quality & Efficiency