For most honey sales, the standard choice is a 200 micron filter. This size is effective at removing common impurities like beeswax and propolis while allowing for efficient processing. If your goal is to produce exceptionally clear honey for competitions, a finer 75 micron filter will yield a superior visual product suitable for the "show-bench."

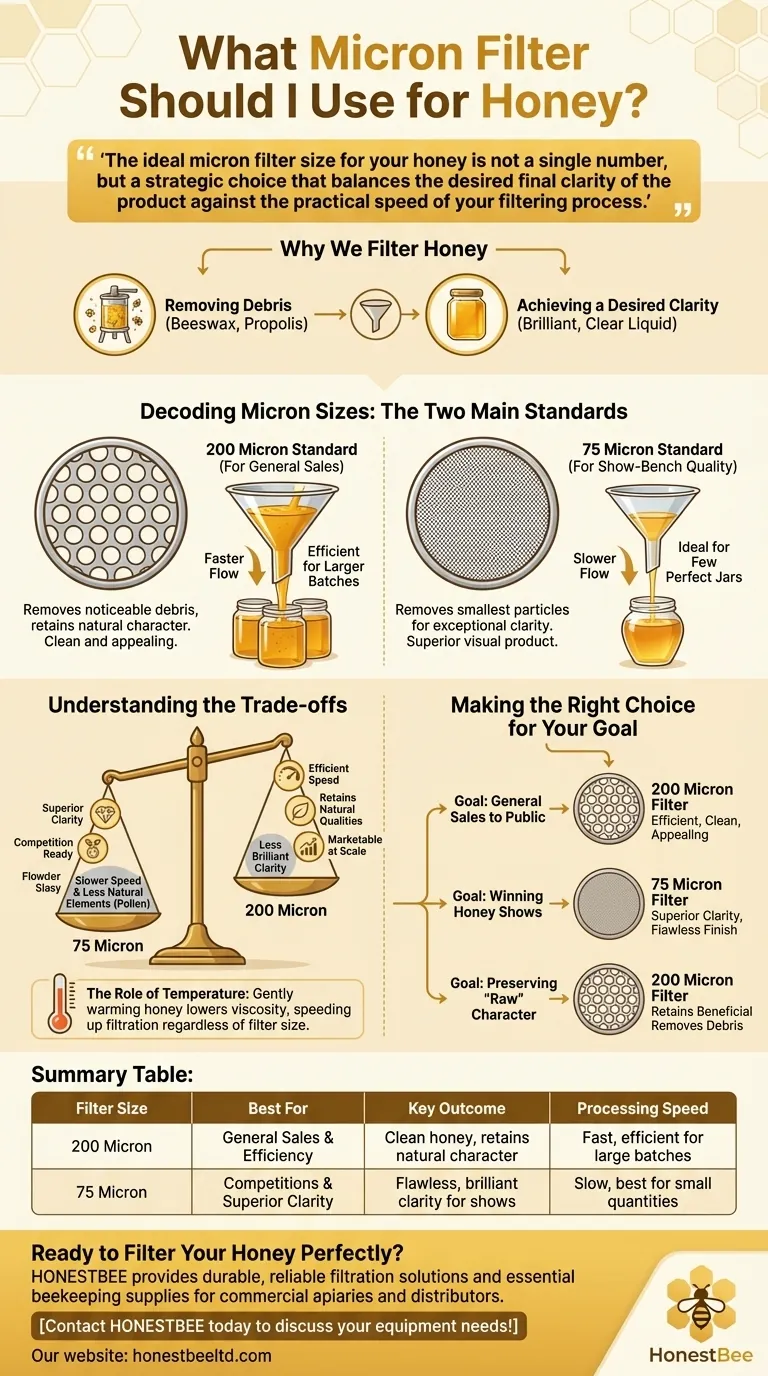

The ideal micron filter size for your honey is not a single number, but a strategic choice that balances the desired final clarity of the product against the practical speed of your filtering process.

Why We Filter Honey

Filtering is a critical step that transforms raw honey from the hive into a stable, marketable product. The primary goals are simple but essential for quality.

Removing Debris

Raw honey directly from the extractor contains various particles you don't want in the final jar. This includes bits of beeswax, propolis, and other hive debris. Filtering ensures a clean, pure product.

Achieving a Desired Clarity

For many consumers and especially for honey shows, visual appeal is paramount. Filtering removes the fine suspended particles that can make honey look cloudy, resulting in a brilliant, clear liquid.

Decoding Micron Sizes: The Two Main Standards

The micron number on a filter refers to the size of the holes in the mesh. A smaller number means smaller holes, resulting in a finer filtration.

The 200 Micron Standard (For General Sales)

A 200 micron filter is the most common and practical choice for beekeepers selling honey. It's fine enough to remove all noticeable debris but coarse enough to allow honey to flow through at a reasonable rate, making it suitable for larger batches.

This level of filtration results in a product that is clean and appealing to the average customer while retaining much of its natural character.

The 75 Micron Standard (For Show-Bench Quality)

For competitions, appearance is a major judging criterion. A 75 micron filter provides a much finer level of filtration, removing even the smallest particles to produce honey with exceptional clarity.

Because the mesh is so fine, the filtering process is significantly slower. This makes it impractical for large quantities but ideal for preparing a few perfect jars for a show.

Understanding the Trade-offs

Choosing a filter size is a balancing act. What you gain in one area, you may sacrifice in another.

Clarity vs. Natural Qualities

While a 75 micron filter produces a visually stunning product, this aggressive filtration can also remove some of honey's naturally occurring and beneficial components, such as fine pollen grains. A 200 micron filter provides a better balance for those who want a clean product that still feels more "raw" or natural.

Processing Speed vs. Volume

There is a direct relationship between micron size and workflow. Honey flows much more slowly through a 75 micron filter, which will also clog more quickly. For anyone processing more than a few gallons, a 200 micron filter is far more efficient.

The Role of Temperature

Gently warming your honey (not to the point of pasteurization) will significantly lower its viscosity. This makes it flow much more easily, speeding up the process regardless of the filter size you choose. This is especially helpful when using a fine 75 micron filter.

Making the Right Choice for Your Goal

Your specific objective should dictate your equipment choice.

- If your primary focus is selling to the general public: Use a 200 micron filter to efficiently produce a clean, appealing product at scale.

- If your primary focus is winning at a honey show: Use a 75 micron filter to achieve the superior clarity and flawless finish that judges reward.

- If your primary focus is preserving a "raw" character: A 200 micron filter is often the best choice, removing unwanted debris while retaining beneficial pollen.

Ultimately, selecting the right filter is about matching your tool to your specific vision for the final product.

Summary Table:

| Filter Size | Best For | Key Outcome | Processing Speed |

|---|---|---|---|

| 200 Micron | General Sales & Efficiency | Clean honey, retains natural character | Fast, efficient for large batches |

| 75 Micron | Competitions & Superior Clarity | Flawless, brilliant clarity for shows | Slow, best for small quantities |

Ready to Filter Your Honey Perfectly?

Choosing the right equipment is key to producing high-quality honey, whether for the local market or the show bench. As a trusted wholesale supplier, HONESTBEE provides commercial apiaries and beekeeping equipment distributors with durable, reliable filtration solutions and other essential beekeeping supplies.

Let us help you streamline your operation and enhance your product quality. Contact HONESTBEE today to discuss your equipment needs and explore our wholesale catalog!

Visual Guide

Related Products

- Professional Honey Filter with Tripod Support Stand

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Two-Stage Plastic Honey Filter for Buckets

- Professional Stainless Steel Honey Filter with Support Handle

- Nylon Honey Strainer Square Filter Cloth for Honey Filters

People Also Ask

- What is better, a 100 or 200 micron filter? Find the Right Fit for Your Water System

- What filter size for honey? A Beekeeper's Guide to Straining for Clarity and Quality

- What is the role of filtration in honey processing? Ensure Purity, Clarity, and Shelf Life

- Why is filtering honey considered an essential step in honey processing? Ensure Quality and Commercial Viability

- What are the benefits of drying honey filtering equipment after use? Protect Your Honey Quality & Equipment Investment