The single most important precaution when melting wax is to never apply direct heat from a flame or electric burner. Wax is a flammable material with a low flash point, and direct heat can quickly raise its temperature to a dangerous level, creating a significant fire hazard. Always use an indirect heating method like a double boiler or a dedicated slow cooker, monitor the temperature closely, and never leave melting wax unattended.

Melting wax is deceptively simple, but the risks of fire and severe burns are very real. The key to safety is not a single action but a complete system: controlling the heat source indirectly, constantly monitoring the temperature, and preparing your workspace and yourself before you even begin.

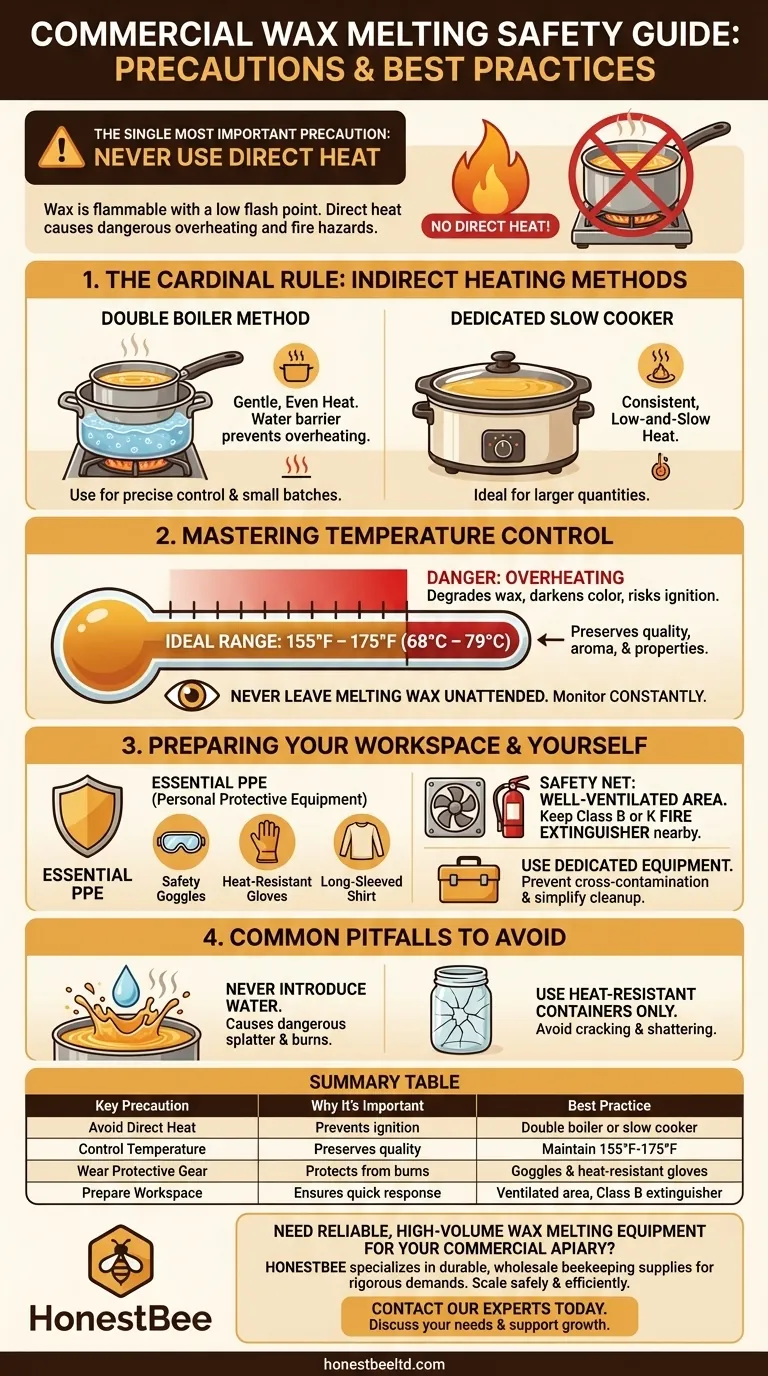

The Cardinal Rule: Avoid Direct Heat

The primary danger in melting wax is its flammability. Placing a pot of wax directly on a stove is an invitation for it to overheat, scorch, and potentially ignite.

Why Direct Heat is a Fire Hazard

Wax, particularly beeswax, can flare up and burn at temperatures around 400°F (204°C). A direct heat source can create hot spots on the bottom of a pan that far exceed the melting point of the wax, bringing it to its flash point with surprising speed.

The Double Boiler Method

The safest and most common method is using a double boiler. This setup involves a larger pot filled with a few inches of simmering water and a smaller, heat-safe pouring pot that sits inside it. The steam and hot water provide gentle, even heat, making it nearly impossible for the wax to overheat. You can easily create a DIY version with a saucepan and a heat-proof glass jar.

Using a Dedicated Slow Cooker

For larger batches, a dedicated slow cooker or crockpot is an excellent alternative. It provides a consistent, low-and-slow heat source that is very easy to control. Simply set it to the low setting and monitor the wax as it melts.

Mastering Temperature Control

Managing the temperature of your wax is crucial not only for safety but also for preserving its quality.

The Ideal Temperature Range

Most waxes melt effectively between 155°F and 175°F (68°C to 79°C). Heating wax beyond this range offers no benefit and introduces unnecessary risk and degradation.

Why Overheating Degrades Your Wax

Exceeding the ideal temperature can ruin the wax itself. Overheating can darken its color, diminish its natural aroma, and, in the case of beeswax, destroy its beneficial anti-microbial properties.

The Importance of Constant Monitoring

Never walk away from melting wax. Keep a constant eye on the process. If you are using a double boiler, ensure the water does not evaporate completely, as this would be equivalent to applying direct heat.

Preparing Your Workspace and Yourself

Proper preparation is just as important as the melting process itself. Treat hot wax with the same respect you would treat hot cooking oil.

Essential Personal Protective Equipment (PPE)

Protect yourself from accidental splashes and burns. Always wear safety goggles, heat-resistant gloves, and a long-sleeved shirt to cover your arms.

Your Safety Net: Fire Extinguisher and Ventilation

Keep a fire extinguisher rated for grease fires (Class B or K) within easy reach. Work in a well-ventilated area to prevent the buildup of any fumes from the wax or added fragrances.

Use Dedicated Equipment

Wax is notoriously difficult to clean from kitchen utensils and pots. It is highly advisable to use dedicated equipment solely for your wax projects to avoid cross-contamination and simplify cleanup.

Common Pitfalls to Avoid

Beyond the basics, a few common mistakes can lead to dangerous situations.

Introducing Water into Hot Wax

Never allow water to get into your melted wax. Even a small amount of water can flash to steam, causing the hot wax to splatter violently and potentially cause severe burns. Ensure your pouring pot and all utensils are completely dry.

Pouring into Unsuitable Containers

When you are ready to pour, make sure your final containers are heat-resistant. Pouring hot wax into a container that cannot withstand the temperature can cause it to crack or shatter.

Making the Right Choice for Your Process

Your approach should be guided by your specific goals and scale.

- If your primary focus is safety and small batches: The double boiler method offers the most precise control and is the universally recommended starting point.

- If you need to melt larger quantities frequently: Investing in a dedicated slow cooker provides consistent, low-and-slow heat that is efficient and reliable.

- If your primary focus is preserving natural wax properties: Strict temperature control below 175°F is non-negotiable to maintain the wax's original color, aroma, and unique qualities.

By understanding the principles of indirect heat and preparation, you can ensure a safe and successful outcome for any project involving melted wax.

Summary Table:

| Key Precaution | Why It's Important | Best Practice |

|---|---|---|

| Avoid Direct Heat | Prevents wax from overheating and igniting. | Use a double boiler or slow cooker. |

| Control Temperature | Preserves wax quality and prevents degradation. | Maintain temperature between 155°F-175°F (68°C-79°C). |

| Wear Protective Gear | Protects from splashes and severe burns. | Use safety goggles and heat-resistant gloves. |

| Prepare Workspace | Ensures quick response to accidents. | Work in a ventilated area with a Class B fire extinguisher nearby. |

Need reliable, high-volume wax melting equipment for your commercial apiary?

At HONESTBEE, we specialize in supplying durable, wholesale-focused beekeeping supplies and equipment designed for the rigorous demands of commercial operations and distributors. Our products help you work safely and efficiently at scale.

Contact our experts today to discuss your specific needs and discover how we can support your business's growth.

Visual Guide

Related Products

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

People Also Ask

- How to clean wax after extracting honey? Master the Cold Wash vs. Melting Methods

- How does the machine flatten the beeswax? A Guide to Roller and Press Methods

- What is the final step in making beeswax foundation sheets? Achieving Perfect Fit for a Productive Hive

- What are the steps involved in preparing wax sheets for milling? Master Temperature Control for Perfect Foundation

- What are the main components of a beeswax foundation sheet machine? A Guide to Efficient Production