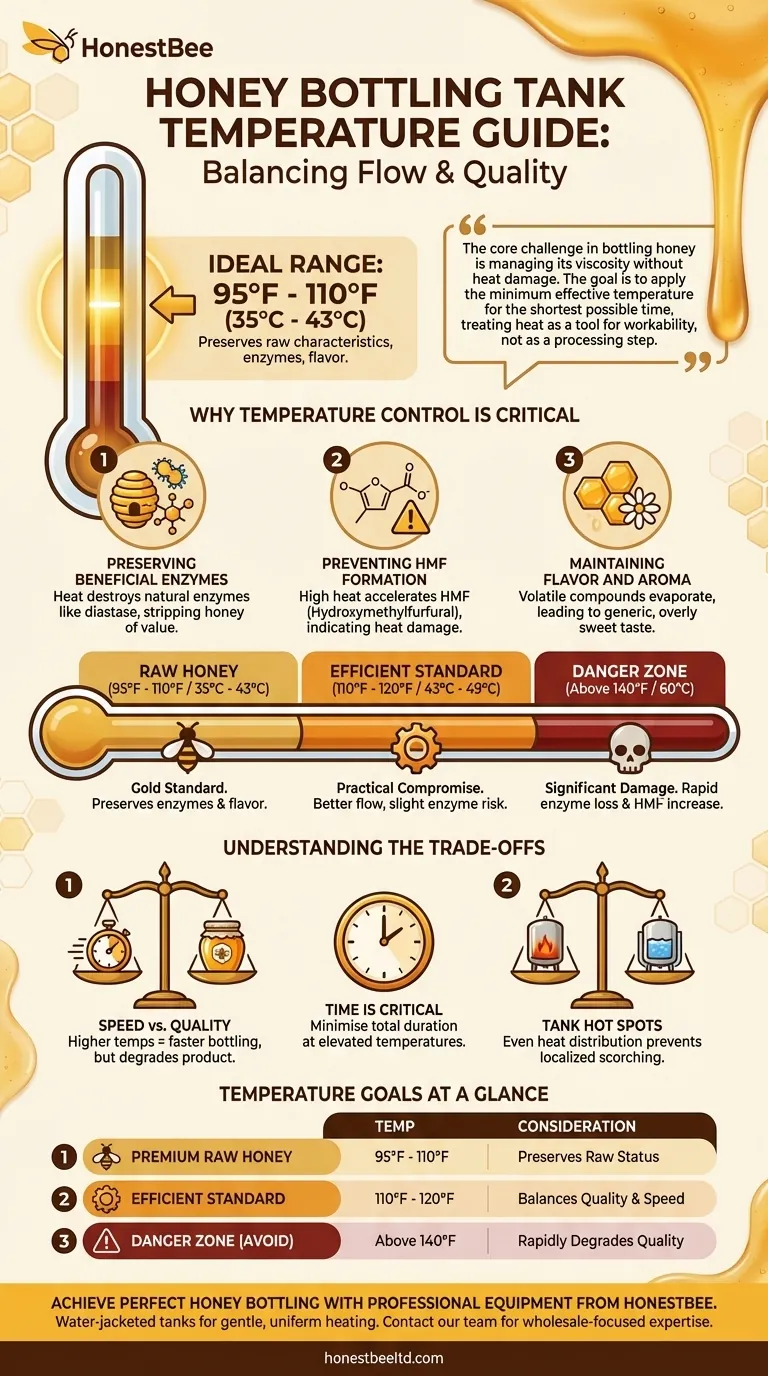

For a honey bottling tank, the ideal temperature is a careful balance between making the honey fluid enough to bottle and preserving its delicate quality. The recommended range for maintaining raw honey characteristics is 95°F to 110°F (35°C to 43°C). While some producers may go up to 120°F (49°C) for faster bottling, exceeding this temperature risks degrading the honey's natural enzymes, flavor, and color.

The core challenge in bottling honey is managing its viscosity without heat damage. The goal is to apply the minimum effective temperature for the shortest possible time, treating heat as a tool for workability, not as a processing step.

Why Temperature Control is Critical for Honey Quality

Heating honey is a functional necessity to make it flow, but excessive or prolonged heat fundamentally alters its composition. Understanding what you're trying to protect is the first step toward determining the correct temperature.

Preserving Beneficial Enzymes

Raw honey contains natural enzymes like diastase and invertase, which are introduced by the bees. These enzymes are key indicators of high-quality, unprocessed honey and are extremely sensitive to heat.

Even moderate temperatures can quickly destroy these enzymes, effectively stripping the honey of one of its most valuable properties.

Preventing HMF Formation

Hydroxymethylfurfural (HMF) is a compound formed when the sugars in honey break down due to heat. While present in trace amounts naturally, HMF levels are a globally recognized standard for measuring heat damage and age.

High temperatures dramatically accelerate HMF formation, which can negatively impact the honey's quality and value.

Maintaining Flavor and Aroma

Each honey varietal has a unique profile of delicate, volatile compounds that create its signature flavor and aroma.

Heat causes these compounds to evaporate, resulting in a generic, overly sweet taste. Gentle warming protects the honey's unique terroir.

Recommended Temperature Ranges

The right temperature depends entirely on your goal. There is no single correct number, but there are distinct tiers of safety and quality.

For "Raw" Honey: 95°F - 110°F (35°C - 43°C)

This is the gold standard for artisanal and premium honey. This temperature range gently mimics the conditions inside a warm beehive, ensuring the honey is fully protected.

Bottling will be slower at these temperatures, but the integrity of the enzymes, flavor, and raw status is maintained.

For Efficient Standard Bottling: 110°F - 120°F (43°C - 49°C)

This range provides a noticeable improvement in honey flow for more efficient production.

While there is a slightly higher risk of minor enzyme degradation compared to the "raw" range, it represents a practical compromise for many producers who prioritize both quality and workflow.

The Absolute Danger Zone: Above 140°F (60°C)

At 140°F (60°C), significant damage to enzymes and a rapid increase in HMF levels begin.

Temperatures approaching 160°F (71°C), often used for pasteurization, will permanently destroy the honey's natural character. It may not "burn" in a culinary sense, but its beneficial properties will be lost.

Understanding the Trade-offs

Choosing a temperature is not just about a setting on a dial; it's about balancing competing priorities.

Speed vs. Quality

This is the central trade-off. Higher temperatures make honey less viscous, allowing for faster straining and bottling.

However, every degree you increase the temperature above the beehive's natural state incrementally degrades the final product.

Time as a Critical Factor

Damage is a function of both temperature and time. Holding honey at a "safe" 120°F for 24 hours can be far more destructive than quickly warming it to the same temperature for just a few hours.

Your goal should always be to minimize the total duration the honey is held at an elevated temperature.

Tank Hot Spots

The design of your bottling tank is crucial. A tank with poor heat distribution can create "hot spots" where honey near the heating element is scorched, even if the thermostat is set to a safe temperature.

Using a water-jacketed tank provides gentle, even heat and is the industry standard for preventing this kind of localized damage.

Making the Right Choice for Your Goal

Select your temperature based on your product, your market, and your priorities.

- If your primary focus is premium "raw" honey: Stay strictly within the 95°F - 110°F (35°C - 43°C) range and minimize heating time.

- If your primary focus is efficient production for a general market: A temperature of 110°F - 120°F (43°C - 49°C) is a workable compromise, but aim to bottle quickly and cool the honey afterward.

- If you are dealing with highly crystallized honey: Gently warming it within these safe ranges is the correct approach. Never use high heat as a shortcut to liquefy it.

Ultimately, your bottling tank's temperature setting is a direct reflection of your commitment to the quality of your final product.

Summary Table:

| Goal | Recommended Temperature Range | Key Consideration |

|---|---|---|

| Premium Raw Honey | 95°F - 110°F (35°C - 43°C) | Preserves enzymes, flavor, and raw status. |

| Efficient Standard Bottling | 110°F - 120°F (43°C - 49°C) | Balances quality with faster production speed. |

| Danger Zone (Avoid) | Above 140°F (60°C) | Rapidly degrades enzymes, flavor, and increases HMF. |

Achieve Perfect Honey Bottling with Professional Equipment from HONESTBEE

Choosing the right temperature is only half the battle. Preventing damaging hot spots requires a well-designed tank with even heat distribution. As a trusted supplier to commercial apiaries and beekeeping equipment distributors, HONESTBEE provides high-quality, water-jacketed honey bottling tanks that deliver gentle, uniform heating to protect your honey's delicate quality during high-volume bottling.

Let our wholesale-focused expertise help you scale your operation without compromising on quality. Contact our team today to discuss the right bottling solutions for your business.

Visual Guide

Related Products

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Manual Honey Filling Machine Bottling Machine for Honey

People Also Ask

- Why is the integration of automated honey-filling machines necessary? Scale Your Commercial Honey Production Line

- How do automated honey-filling machines improve the honey post-processing stage? Scale Your Apiary Efficiency

- How do automatic honey-filling machines facilitate the transition to retail? Professional Solutions for Beekeeping

- What value do automatic honey-filling machines offer? Scaling Commercial Honey Production with Precision

- What is the significance of automated filling and labeling systems in honey quality? Build Consumer Trust with Precision