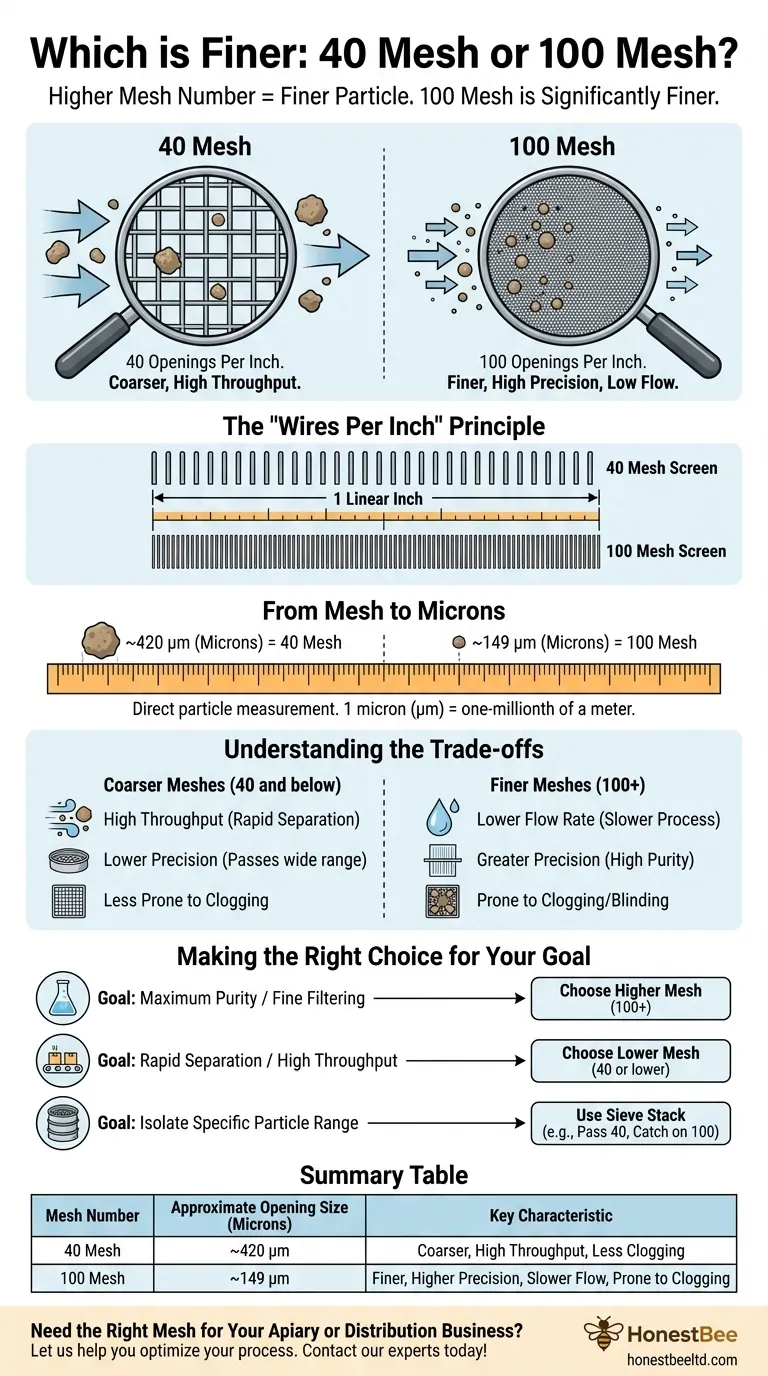

In the mesh sizing system, a higher number signifies a finer particle. Therefore, 100 mesh is significantly finer than 40 mesh. The mesh number refers to the number of openings per linear inch of a screen; a 100 mesh screen has more wires and smaller openings than a 40 mesh screen, allowing it to capture smaller particles.

The core principle to remember is that the mesh number is not a measure of the particle itself, but a measure of the screen's density. A higher mesh number means more wires per inch, which results in smaller holes and therefore correlates to a finer particle size.

How Mesh Size Defines Fineness

To properly use mesh sizing, you must understand that the number is an indirect measurement. It describes the tool, not the material directly.

The "Wires Per Inch" Principle

The mesh number is determined by counting the number of openings in one linear inch of a screen or sieve.

A 40 mesh screen has 40 openings per inch.

A 100 mesh screen packs 100 openings into that same linear inch.

More Wires, Smaller Holes

To fit 100 openings into the same space where another screen fits only 40, the individual wires must be closer together and the resulting openings must be much smaller.

This is the fundamental reason a higher mesh number corresponds to a finer particle size. A powder that passes through a 40 mesh screen might be trapped by a 100 mesh screen because the holes are too small for it to pass.

From Mesh to Microns

The physical size of particles is often measured in microns (µm), where one micron is one-millionth of a meter. This provides a direct measurement of particle diameter.

A standard 40 mesh screen has openings of approximately 420 microns.

In contrast, a 100 mesh screen has openings of only 149 microns, which is why it stops much finer particles.

Understanding the Practical Trade-offs

Choosing a mesh size is not just about fineness; it involves balancing precision against processing speed and potential issues.

The Challenge of Finer Meshes (100+)

Finer meshes provide greater precision, allowing you to filter out very small contaminants or create powders with a very small, consistent particle size.

However, their small openings mean they have a lower flow rate and are much more prone to clogging or "blinding," especially with moist or irregularly shaped materials.

The Benefit of Coarser Meshes (40 and below)

Coarser meshes allow for a much higher throughput, making them ideal for quickly sifting large volumes of material where only the largest particles need to be removed.

The trade-off is a lack of precision. A coarse screen will only stop large particles and will let a wide range of smaller sizes pass through.

Making the Right Choice for Your Goal

Selecting the correct mesh depends entirely on the outcome you need to achieve for your specific process.

- If your primary focus is maximum purity or fine filtering: Choose a higher mesh number (like 100 or greater) to remove the smallest possible particles.

- If your primary focus is rapid separation or high throughput: Choose a lower mesh number (like 40 or lower) to quickly process material without clogging.

- If your primary focus is isolating a specific particle size range: Use a stack of sieves, such as letting material pass through a 40 mesh screen but be caught by a 100 mesh screen below it.

Understanding this inverse relationship between mesh number and particle size empowers you to select the precise tool for your specific technical requirement.

Summary Table:

| Mesh Number | Approximate Opening Size (Microns) | Key Characteristic |

|---|---|---|

| 40 Mesh | ~420 µm | Coarser, high throughput, less prone to clogging |

| 100 Mesh | ~149 µm | Finer, higher precision, slower flow, prone to clogging |

Need the Right Mesh for Your Apiary or Distribution Business?

Choosing the correct mesh size is critical for processing pollen, propolis, or creating consistent powdered supplements. HONESTBEE supplies high-quality, durable sieves and screens tailored for commercial beekeeping and equipment distributors. Our wholesale-focused operations ensure you get the reliable equipment you need for efficient, precise sorting.

Let us help you optimize your process. Contact our experts today to discuss your specific mesh and equipment requirements!

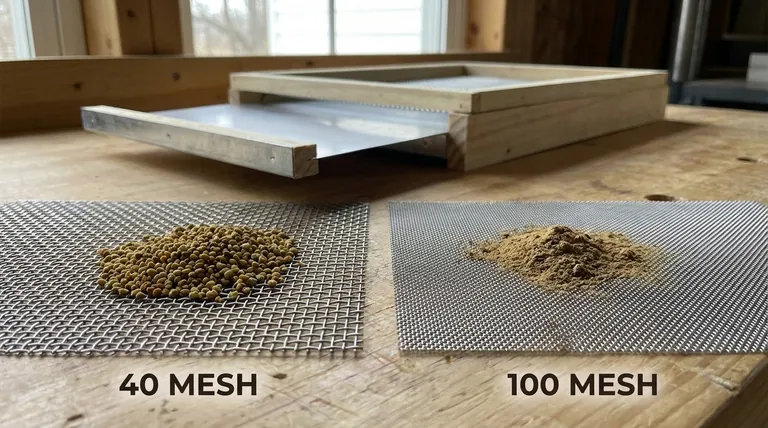

Visual Guide

Related Products

- Australian Pine Wood Langstroth Screen Bottom Board for Wholesale

- Langstroth Screen Bottom Board for Beekeeping Wholesale

- HONESTBEE Adjustable Voltage Wire Embedder with Digital Display

- Professional Adjustable Timer Electric Wire Embedder

- Wood and Mesh Push-In Queen Cage

People Also Ask

- Why do some beekeepers switch between screened and solid bottom boards? Optimize Your Hive's Health Year-Round

- What are the potential disadvantages of using a screened bottom board? Hidden Risks for Your Apiary Management

- What are the benefits of using a screened bottom board and in which climate is it recommended? Optimize Hive Health

- How does a screened bottom board benefit the hive during the summer? Boost Ventilation & Pest Control

- What additional benefit does a screened bottom board offer? Boost Hive Health & Mite Control