At its core, tamper-evident packaging serves as a critical security feature that guarantees the safety and integrity of honey from the moment it is sealed to when it reaches the consumer. These features, such as shrink bands or pop-top lids, provide an immediate, visible confirmation that the product has not been opened or contaminated.

The primary function of a tamper-evident feature is to provide undeniable proof of a container's status. However, its deeper importance lies in acting as the final, visible symbol of a comprehensive quality control process, building essential consumer trust in the product's purity and safety.

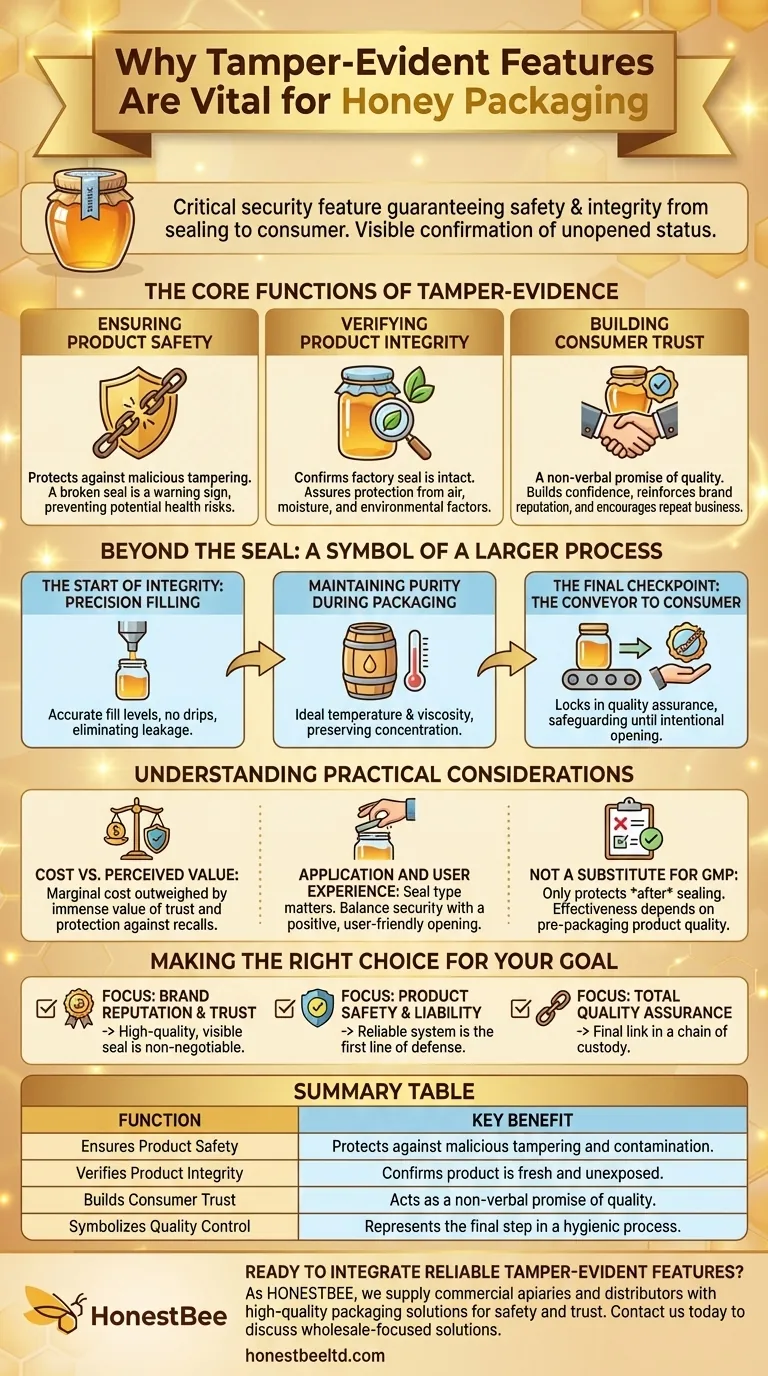

The Core Functions of Tamper-Evidence

A simple seal performs several critical jobs that are vital for both the consumer and the producer. Understanding these functions reveals why they are an industry standard, not an optional extra.

Ensuring Product Safety

The most obvious benefit is protection against malicious tampering. A broken seal is an unmistakable warning sign.

This visual cue allows consumers, retailers, and distributors to immediately identify and reject a container that may have been compromised, preventing potential health risks from contamination.

Verifying Product Integrity

Beyond deliberate interference, tamper-evident seals also protect against accidental issues. They confirm that the factory seal is intact.

An unbroken seal assures the consumer that the honey has not been exposed to air, moisture, or other environmental factors during shipping and stocking, preserving its intended freshness and quality.

Building Consumer Trust

In a crowded marketplace, trust is a valuable currency. A tamper-evident feature is a non-verbal promise of quality from the producer.

Seeing an intact seal gives the customer instant confidence in the safety and authenticity of the purchase, which directly reinforces brand reputation and encourages repeat business.

Beyond the Seal: A Symbol of a Larger Process

The tamper-evident seal is the final checkpoint in a series of quality control measures that begin long before the lid is secured. It represents the culmination of a careful packaging process.

The Start of Integrity: Precision Filling

Product integrity begins at the filling stage. Modern packaging machinery uses precise shut-off valves and suck-back devices.

These mechanisms prevent drips and ensure accurate fill levels, eliminating leakage that could compromise the container and the seal later in the process.

Maintaining Purity During Packaging

High-quality honey packaging lines often use equipment like double-layer insulated barrels.

This technology maintains the honey's ideal temperature and viscosity, ensuring its concentration and purity are preserved throughout the packaging operation, right up to the point of sealing.

The Final Checkpoint: The Conveyor to Consumer

From filling to sealing to labeling, the product moves along an automated conveying system. The tamper-evident feature is the last step in this controlled journey.

It effectively locks in all the prior quality assurance efforts, safeguarding the product until it is intentionally opened by the end-user.

Understanding the Practical Considerations

While essential, implementing tamper-evident features is not without its own set of considerations. Objectively weighing them is key to making the right choice.

Cost vs. Perceived Value

Adding a shrink band, inner seal, or specialized lid adds a marginal cost to each unit.

However, this cost is almost always outweighed by the immense value of consumer trust and protection against the catastrophic financial and reputational damage of a product recall.

Application and User Experience

The type of seal matters. A shrink band that is difficult to remove or an inner foil seal that tears improperly can create frustration for the consumer.

The choice of feature should balance security with a positive, user-friendly opening experience.

Not a Substitute for Good Manufacturing Practices

A tamper-evident seal cannot fix a product that was already compromised. It only protects what's inside after it has been sealed.

Its effectiveness is entirely dependent on the product being pure and safe at the moment of packaging. The seal is a guarantee of post-packaging security, not pre-packaging quality.

Making the Right Choice for Your Goal

Your packaging strategy should align with your primary business objectives.

- If your primary focus is brand reputation and consumer trust: A high-quality, clearly visible tamper-evident seal is a non-negotiable marketing and safety tool.

- If your primary focus is product safety and liability reduction: Implementing a reliable tamper-evident system is your first line of defense against contamination and potential legal issues.

- If your primary focus is total quality assurance: View the tamper-evident feature as the final, crucial link in a chain of custody that begins with hygienic handling and precision filling.

Ultimately, a tamper-evident seal transforms your packaging from a simple container into a clear statement of quality, safety, and care.

Summary Table:

| Function | Key Benefit |

|---|---|

| Ensures Product Safety | Protects against malicious tampering and contamination. |

| Verifies Product Integrity | Confirms the product is fresh and hasn't been exposed to air or moisture. |

| Builds Consumer Trust | Acts as a non-verbal promise of quality, reinforcing brand reputation. |

| Symbolizes Quality Control | Represents the final step in a comprehensive, hygienic packaging process. |

Ready to integrate reliable tamper-evident features into your honey packaging line? As HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the high-quality packaging supplies and equipment needed to ensure product safety and build unwavering consumer trust. Contact us today to discuss how our wholesale-focused solutions can enhance your quality assurance process.

Visual Guide

Related Products

- Classic Honey Bear Jars with Flip Top Dispensing Cap for Liquid Sweeteners

- Stainless Steel Beekeeping Honey Extractor Lid

- Inverted Squeezable Honey Jar with No Drip Flip Top Cap for Easy Pouring

- Professional Water Cooled Induction Sealing Machine for Bottles and Containers

- Modern Honeycomb Pattern Wooden Honey Dipper for Stirring and Drizzling

People Also Ask

- Can honey go bad in the heat? Protect Your Honey's Quality and Flavor

- What is done with the honey after extraction and filtering? From Purification to Perfect Packaging

- What is honey bear packaging, and why is it popular? Unpacking Its Marketing Power

- What are the limitations of plastic honey containers? Impact on Environment & Brand Perception

- What is the role of industrial-grade honey packaging materials? Ensure Integrity and Market Success