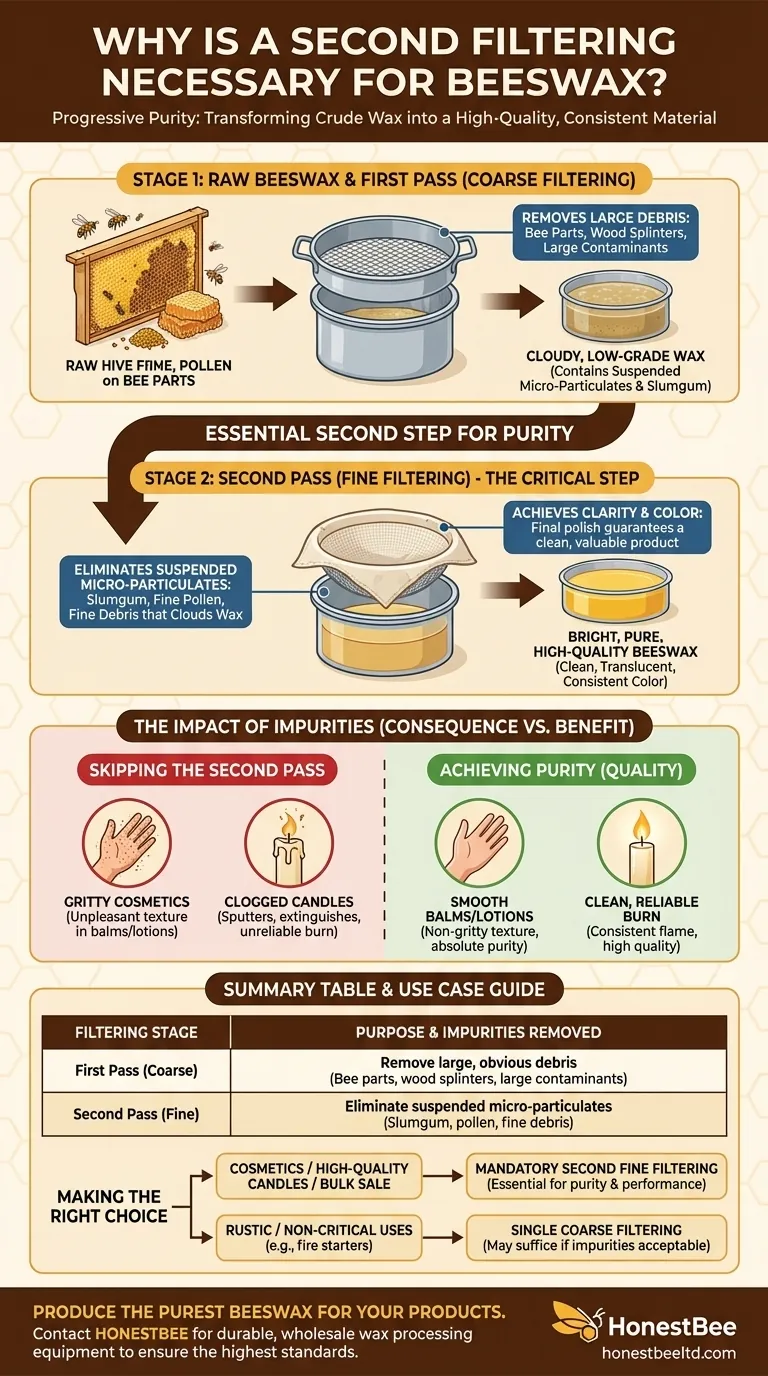

A second filtering is essential for transforming raw beeswax from a crude, debris-filled state into a pure, high-quality material ready for use. While the initial melt and coarse filtering remove large contaminants, a second, finer filtration step is required to eliminate the suspended micro-particulates that remain. This final polish is what guarantees a clean, valuable, and consistent final product.

The core purpose of beeswax rendering is progressive clarification. Your first pass removes large, obvious debris like bee parts and wood splinters, but only a second, finer filtering can remove the suspended "slumgum" and fine particulates that cloud the wax and compromise its quality.

The Goal of Wax Rendering: Progressive Purity

Processing beeswax is not a single action but a multi-stage process of purification. Understanding what you are removing at each stage is key to appreciating why the second step is so critical.

What "Raw" Beeswax Contains

Raw cappings and burr comb straight from the hive are a mixture of wax and many other materials. These impurities often include dirt, wood splinters from the frames, pollen, propolis, and leftover honey. Most significantly, it contains fine particulates and what beekeepers call slumgum—the dark residue of old cocoons, pollen, and other non-wax hive debris.

The First Pass: Removing Obvious Debris

The initial rendering, typically done with heat and water, melts the wax and allows it to separate from the heaviest debris. This is often followed by a coarse filtering step through something like a metal sieve or burlap. This first pass successfully removes large, visible contaminants but is not fine enough to capture everything.

Why a Second Filter is Non-Negotiable for Quality

The difference between cloudy, low-grade wax and bright, pure beeswax lies in the second filtering stage. This step targets the contaminants that the first pass leaves behind.

Targeting Suspended Micro-Particulates

After the first rendering, tiny particles of slumgum, pollen, and other debris remain suspended throughout the melted wax. They are too small to be caught by a coarse filter and often too light to sink completely during the initial separation. A second, slower melt followed by a pass through a finer filter—like cheesecloth, felt, or a paper towel—is necessary to trap these fine impurities.

Achieving Purity and Color

These suspended particles are what give unrefined wax a cloudy, dull, or overly dark appearance. By removing them, you not only increase the purity but also significantly improve the color and clarity of the finished block. Clean beeswax has a characteristic bright yellow hue and translucence that is highly desirable for most applications.

Understanding the Trade-offs

While a second filtering is the standard for high-quality wax, it's important to understand the consequences of skipping it. The need for this step is directly related to the intended use of the final product.

The Impact of Impurities on Final Products

For applications like cosmetics or lip balms, any remaining particulates will result in a gritty and unpleasant texture. For candlemaking, these impurities can be drawn up the wick as the candle burns, causing it to clog, sputter, or extinguish itself. This drastically reduces the quality and reliability of the candle.

When a Single Pass Might Suffice

If your only goal is to create rustic fire-starters or to use the wax for a task where purity is irrelevant, such as waterproofing old tools or wood, a single coarse filtering might be "good enough." However, for any product intended for sale, personal care, or reliable performance, the second step is not optional.

Making the Right Choice for Your Goal

The level of filtering your beeswax requires is dictated entirely by its final purpose.

- If your primary focus is cosmetic-grade products (balms, lotions): A second, fine filtering is mandatory to ensure a smooth, non-gritty texture and absolute purity.

- If your primary focus is high-quality candles: Double filtering is essential to prevent wick clogging and ensure a clean, consistent, and reliable burn.

- If your primary focus is selling bulk wax: A second filtering is the standard for producing a bright, clean, and valuable product that will command a better price.

- If your primary focus is non-critical rustic uses (e.g., fire starters): A single coarse filtering may be sufficient if minor impurities are acceptable.

Ultimately, this two-step process ensures your effort results in a pure, valuable product worthy of the hive.

Summary Table:

| Filtering Stage | Purpose | Impurities Removed |

|---|---|---|

| First Pass (Coarse) | Remove large, obvious debris | Bee parts, wood splinters, large contaminants |

| Second Pass (Fine) | Eliminate suspended micro-particulates | Slumgum, pollen, fine debris that clouds wax |

Produce the purest beeswax for your products.

Whether you're a commercial apiary producing cosmetic-grade wax or a distributor supplying candlemakers, the right equipment is key to a profitable, high-quality yield. HONESTBEE supplies the durable, wholesale-focused beekeeping supplies and wax processing equipment you need to ensure every batch meets the highest standards of purity and clarity.

Contact HONESTBEE today to discuss your commercial or distribution needs and elevate your wax quality.

Visual Guide

Related Products

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- 10L Stainless Steel Electric Honey Press Machine

People Also Ask

- What are the main benefits of using a honey-wax separating screw press? Boost Yield and Efficiency for Your Apiary

- What happens to the wax after extraction by the Wax Screw Press? Efficient Post-Extraction Processing Guide

- What is the purpose of the Wax Screw Presses set? Maximize Honey & Wax Yield Efficiently

- What is the primary function of a honey screw press? Maximize Yield with Advanced Cold Press Separation Technology

- How does a honey screw press operate to separate honey from wax? Boost Your Apiary Efficiency