Inspecting and replacing filters in your honey equipment is a critical maintenance task that directly protects the quality of your product and the health of your machinery. Worn-out or clogged filters fail to remove impurities, reduce the efficiency of your entire workflow, and can lead to premature equipment failure. This simple act of maintenance is fundamental to producing clean, high-quality honey.

The core purpose of filter maintenance goes beyond simple cleaning. It is a crucial control point that preserves your honey's market value, ensures your operational efficiency, and extends the lifespan of your valuable equipment.

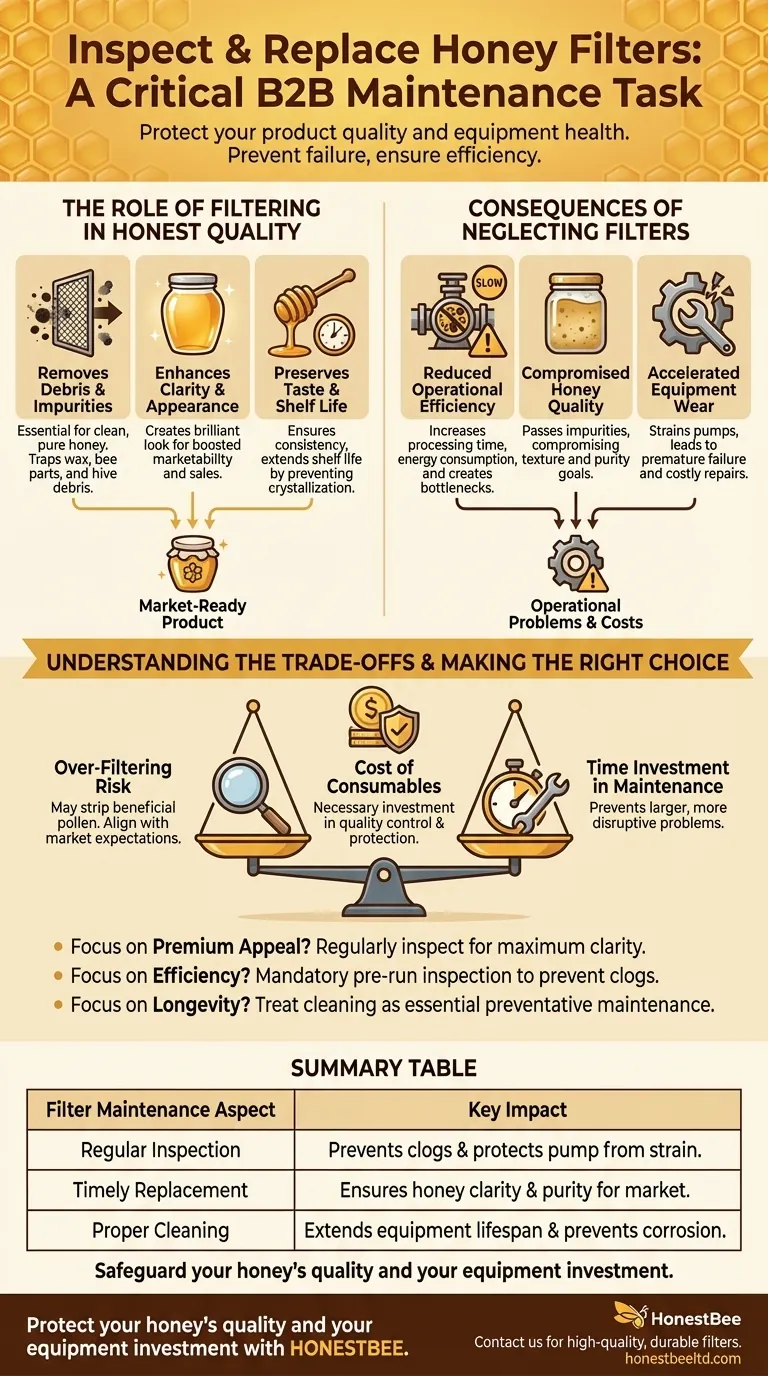

The Role of Filtering in Honey Quality

A properly functioning filter is the gatekeeper between raw, extracted honey and a market-ready product. Its performance directly impacts the final quality in several key areas.

Removing Debris and Impurities

The primary job of a filter is to remove physical debris from the honey. This includes wax particles, bee parts, and other hive debris that are naturally present after extraction.

This step is essential to produce clean, pure honey suitable for bottling and consumption.

Enhancing Clarity and Appearance

Filtering creates the clear, brilliant appearance that many consumers associate with high-quality honey. By removing fine particles like pollen and wax, the process improves the product's visual appeal.

This enhanced clarity and clean look can significantly boost marketability and sales.

Preserving Taste and Shelf Life

Impurities left in honey can potentially affect its taste and texture over time. Proper filtering ensures a consistent product and can help extend its shelf life by removing particles that might encourage crystallization or other changes.

The Consequences of Neglecting Filters

Failing to inspect, clean, and replace filters is not a shortcut; it's a direct path to operational problems and a lower-quality product.

Reduced Operational Efficiency

A clogged or worn-out filter drastically slows down the filtering process. Your pump has to work harder to force the honey through, increasing processing time and energy consumption.

This inefficiency creates a bottleneck in your production line, costing you valuable time.

Compromised Honey Quality

A filter that is past its prime will fail to capture all debris. This allows impurities to pass into your final product, compromising the clarity, texture, and purity you worked hard to achieve.

Accelerated Equipment Wear

The increased pressure caused by a clogged filter puts significant strain on your pump and other system components. This added stress can lead to premature failure and costly repairs.

Regular maintenance is a small investment to protect the lifespan of your more expensive equipment.

Understanding the Trade-offs

While essential, the filtering process involves balancing competing priorities. Understanding these trade-offs allows you to make informed decisions for your specific goals.

The Risk of Over-Filtering

Using an extremely fine filter can strip honey of beneficial components, particularly pollen. While this produces maximum clarity, some consumers seek out honey with natural pollen, so you must align your filtering level with your target market's expectations.

The Cost of Consumables

Filters are a recurring operational cost. However, viewing this as a necessary investment in quality control and equipment protection is the correct perspective. The cost of a new filter is minimal compared to a damaged pump or a lost batch of honey.

The Time Investment in Maintenance

Proper maintenance requires time. Washing components with warm water, drying them thoroughly to prevent corrosion, and performing regular inspections are all manual tasks. This time is an investment in preventing larger, more disruptive problems down the line.

Making the Right Choice for Your Operation

Your approach to filter maintenance should align directly with your production goals.

- If your primary focus is premium market appeal: Regularly inspect and replace filters to achieve maximum clarity and ensure a visually perfect product free of all impurities.

- If your primary focus is operational efficiency: Make filter inspection a mandatory step before every run to prevent clogs that slow down processing and strain your pump.

- If your primary focus is equipment longevity: Treat filter cleaning and replacement as essential preventative maintenance to avoid the high cost of premature equipment failure.

Ultimately, diligent filter management is the simplest way to safeguard both your honey's quality and your investment in the equipment that produces it.

Summary Table:

| Filter Maintenance Aspect | Key Impact |

|---|---|

| Regular Inspection | Prevents clogs & protects pump from strain. |

| Timely Replacement | Ensures honey clarity & purity for market. |

| Proper Cleaning | Extends equipment lifespan & prevents corrosion. |

Protect your honey's quality and your equipment investment with HONESTBEE.

As a trusted supplier of beekeeping supplies and equipment for commercial apiaries and distributors, we understand the critical role that reliable filters play in your operation. Our high-quality, durable filters are designed to deliver consistent performance, ensuring your honey meets the highest standards of clarity and purity while safeguarding your valuable processing equipment.

Contact HONESTBEE today to discuss your filter and equipment needs! Let our experts help you select the right supplies to maximize your efficiency and protect your product quality.

Visual Guide

Related Products

- Professional Honey Filter with Tripod Support Stand

- Nylon Honey Strainer Square Filter Cloth for Honey Filters

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

- Two-Stage Plastic Honey Filter for Buckets

- Professional Stainless Steel Honey Filter with Support Handle

People Also Ask

- What are the overall benefits of a honey filtering machine? Professionalize Your Beekeeping Operation Now

- How does industrial-grade fine-pore filtration equipment ensure the physical purity of honey? Expert Filtration Guide

- How should honey filtering equipment be maintained? Essential Care for Longevity and Purity

- What are the specific functions of large-scale honey filtering and homogenization systems? Achieve Export Standard Quality

- What is the role of industrial-grade honey filtration and filling systems in mitigating lead contamination?

- How do fermentation tanks and filtration systems support mead production? Elevate Honey into Premium Value-Added Goods

- Why is a filtering step necessary during the preparation of plant and propolis extracts? Ensure Purity and Precision

- What is the process for filtering honey after initial straining? Professional Clarification and Temperature Mastery