For beekeepers and honey processors, extracting pure beeswax from honey residues isn’t just about waste reduction—it’s about unlocking a valuable resource. Whether you’re preparing cosmetic-grade wax or crafting candles, mastering separation techniques ensures maximum purity and yield. Here’s a detailed guide to practical methods, troubleshooting tips, and post-separation applications.

Beeswax Separation Essentials

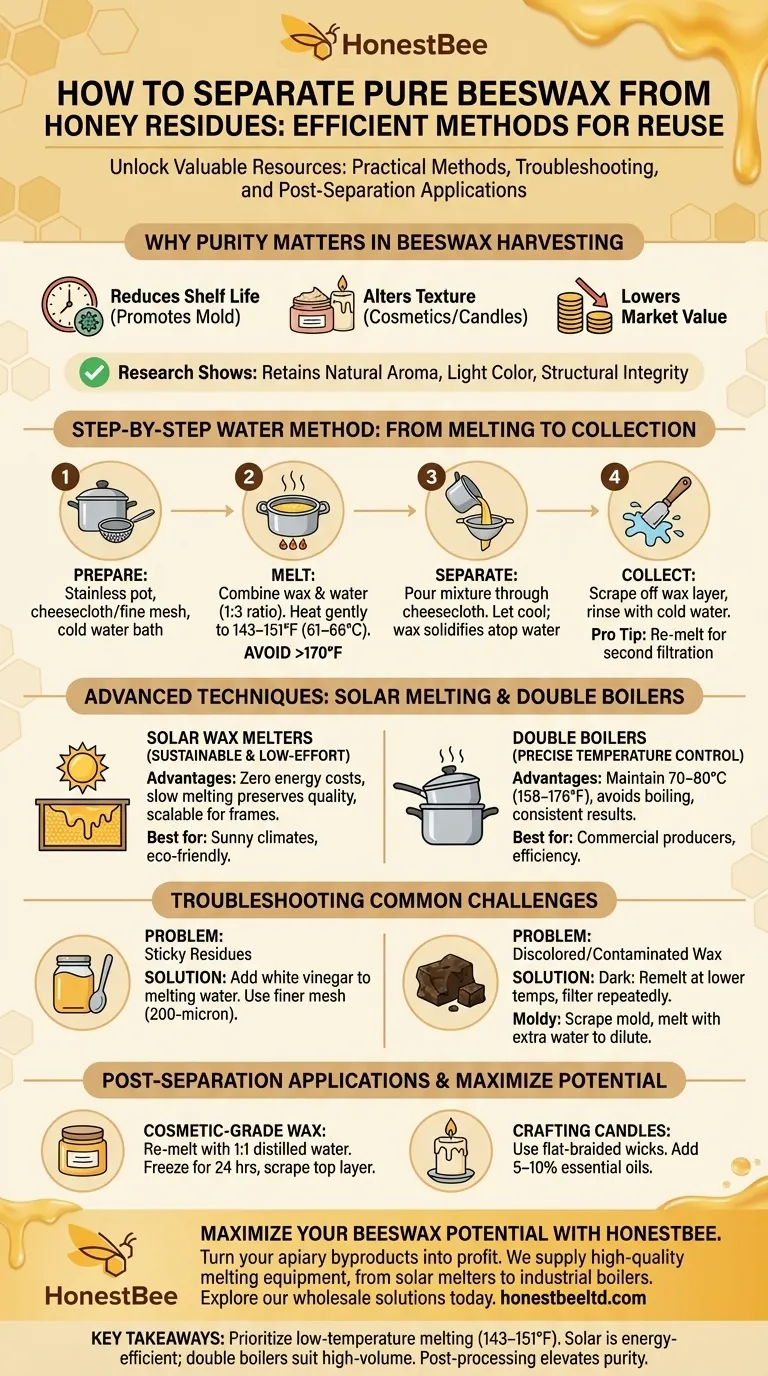

Why Purity Matters in Beeswax Harvesting

Beeswax quality directly impacts its usability. Impurities like honey residues, propolis, or debris can:

- Reduce shelf life (promoting mold growth)

- Alter texture in cosmetics or candle-making

- Lower market value for commercial sales

Research shows that properly separated beeswax retains its natural aroma, light color, and structural integrity—key traits for premium products.

Step-by-Step Water Method: From Melting to Collection

The water method is ideal for small-scale operations and beginners.

-

Prepare Materials:

- Stainless steel pot or double boiler

- Cheesecloth or fine mesh strainer

- Cold water bath

-

Melting Process:

- Combine wax scraps with water in a 1:3 ratio (e.g., 1 cup wax to 3 cups water).

- Heat gently to 143–151°F (61–66°C)—exceeding 170°F (77°C) risks discoloration.

-

Separation and Collection:

- Pour the mixture through cheesecloth to filter debris.

- Let the liquid cool; beeswax solidifies atop the water.

- Scrape off the wax layer, then rinse with cold water to remove residual honey.

Pro Tip: Re-melt the collected wax for a second filtration if impurities persist.

Advanced Techniques: Solar Melting and Double Boilers

Solar Wax Melters

Solar melters are sustainable and low-effort:

-

Advantages:

- Zero energy costs; relies on sunlight.

- Slow melting preserves wax quality.

- Scalable for larger volumes (e.g., compatible with Langstroth or Top-Bar hive frames).

Best for: Beekeepers in sunny climates or those prioritizing eco-friendly methods.

Double Boilers

A double boiler (or bain-marie) offers precise temperature control:

- Maintain 70–80°C (158–176°F) to avoid boiling.

- Ideal for processing larger batches with consistent results.

Best for: Commercial producers needing efficiency.

Troubleshooting Common Challenges

Managing Residual Honey and Debris

- Problem: Sticky residues after separation.

-

Solution:

- Add a tablespoon of white vinegar to the melting water to break down sugars.

- Use a finer mesh (e.g., 200-micron filter) for secondary straining.

Salvaging Discolored or Contaminated Wax

- Dark Wax: Often results from overheating. Remelt at lower temps and filter repeatedly.

- Moldy Wax: Scrape off surface mold, then melt with extra water to dilute contaminants.

Post-Separation Applications

Cosmetic-Grade Wax Preparation

For lip balms or lotions:

- Re-melt purified wax with a 1:1 ratio of distilled water.

- Freeze for 24 hours, then scrape off the top layer—this removes microscopic impurities.

Crafting Candles with Recovered Beeswax

- Wick Selection: Use flat-braided wicks for cleaner burns.

- Additives: Enhance scent with 5–10% essential oils (e.g., lavender or citronella).

Maximize Your Beeswax Potential with HONESTBEE

Turn your apiary byproducts into profit. HONESTBEE supplies commercial beekeepers and distributors with high-quality melting equipment—from solar melters to industrial-grade boilers—ensuring efficient, pure wax extraction. Explore our wholesale solutions today to optimize your harvest.

Key Takeaways:

- Prioritize low-temperature melting (143–151°F) to preserve wax quality.

- Solar melters are energy-efficient; double boilers suit high-volume needs.

- Post-processing (e.g., freezing or vinegar rinses) elevates purity for premium products.

Visual Guide

Related Products

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

Related Articles

- Guide to Separating Beeswax from Honey and Its Uses

- How to Make 100% Pure Beeswax Candles: A Healthier, Brighter Alternative

- How to Purify Beeswax Contaminated with Brood Comb: Maximizing Honey Recovery

- The Unseen Engine of the Hive: Decoding the Economics of Wax Production

- How Beekeepers Turn Old Beeswax into Profitable Ventures