Hive Making Machines

Automatic Finger Joints Joint Making Machine for Bee Box and Hive Making

Item Number : BHJM-1

Price varies based on specs and customizations

- Board Width

- 145-260 mm

- Board Thickness

- Up to 60 mm

- Output

- 360 pcs/h

Shipping:

Contact us to get shipping details Enjoy On-time Dispatch Guarantee.

Why Choose Us

Easy ordering process, quality products, and dedicated support for your business success.

Application

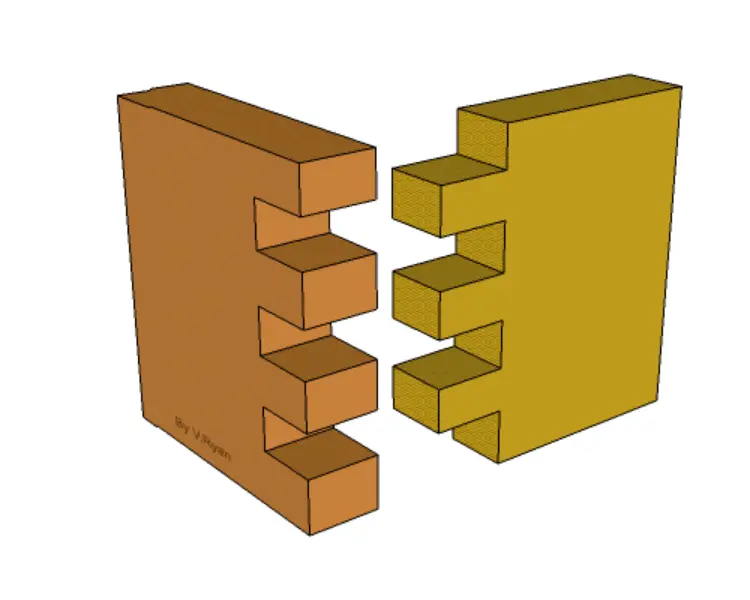

The Finger Joint Bee Box Making Machine is a highly specialized piece of equipment designed to meet the needs of modern beekeeping operations. Its primary application is in the creation of finger joints in wooden boards, which are essential for the assembly of durable and robust bee boxes. This machine is particularly well-suited for commercial bee hive manufacturers, woodworking workshops, and apiary supply producers who require high precision and efficiency in their production processes.

-

Bee Hive Manufacturing: The machine is specifically engineered to produce finger joints in wooden boards used for assembling bee boxes, frames, and other hive components. This ensures that the final products are structurally sound and durable, capable of withstanding the rigors of beekeeping.

-

Custom Hive Designs: With its ability to accommodate boards with a width range of 145–260 mm and a maximum thickness of 60 mm, the machine is ideal for both standard and custom hive designs. This versatility allows manufacturers to create a wide variety of hive configurations to meet specific beekeeping needs.

-

High-Volume Production: The machine’s high-speed output of up to 360 finger-jointed boards per hour makes it an excellent choice for large-scale operations. This efficiency ensures that manufacturers can meet high demand without compromising on quality.

-

Woodworking Workshops: Beyond beekeeping, the machine can also be used in general woodworking applications where strong, interlocking joints are required. This makes it a versatile addition to any woodworking shop.

- Enhanced Durability: The machine creates 5 finger joints per board, ensuring strong, interlocking connections that enhance the durability of the bee boxes.

- Precision and Accuracy: Equipped with durable 180mm diameter blades, the machine delivers clean, accurate cuts, ensuring that each joint is precise and secure.

- Streamlined Production: The integrated control box simplifies operation with intuitive controls for adjusting speed, pressure, and joint parameters, making the production process more efficient.

Feature

The Finger Joint Bee Box Making Machine is packed with features that make it a standout choice for manufacturers looking to enhance their production capabilities. From its high efficiency to its user-friendly design, this machine is built to deliver exceptional performance in demanding production environments.

-

High Efficiency: The machine produces up to 360 finger-jointed boards per hour, maximizing productivity for large-scale operations. This high-speed output ensures that manufacturers can meet high demand without compromising on quality.

-

Powerful Performance: Powered by a three-phase 380V/4 kW motor, the machine delivers reliable energy for continuous operation. This powerful performance ensures that the machine can handle high-volume production with ease.

-

Precision Engineering: The machine is equipped with durable 180mm diameter blades for clean, accurate cuts. This precision engineering ensures that each finger joint is precise and secure, enhancing the durability of the final product.

-

Versatile Compatibility: The machine accommodates boards with a width range of 145–260 mm and a maximum thickness of 60 mm, making it ideal for both standard and custom hive designs. This versatility allows manufacturers to create a wide variety of hive configurations.

-

User-Friendly Design: The integrated control box simplifies operation with intuitive controls for adjusting speed, pressure, and joint parameters. This user-friendly design makes the machine easy to operate, even for those with limited technical expertise.

-

Durability & Customization: Built with heavy-duty materials, the machine is designed to withstand demanding production environments. Additionally, it offers customizable options, allowing manufacturers to tailor blade configurations, board dimensions, or control systems to meet specific manufacturing needs.

- Enhanced Productivity: The high-speed output and powerful performance of the machine ensure that manufacturers can meet high demand without compromising on quality.

- Precision and Accuracy: The precision engineering of the machine ensures that each finger joint is precise and secure, enhancing the durability of the final product.

- Versatility: The machine’s versatile compatibility and customizable options allow manufacturers to create a wide variety of hive configurations, meeting specific beekeeping needs.

Principle

The Finger Joint Bee Box Making Machine operates on the principle of precision engineering and efficient production. The machine is designed to create strong, interlocking finger joints in wooden boards, which are essential for the assembly of durable and robust bee boxes.

-

Board Feeding: The wooden boards are fed into the machine, where they are positioned for the cutting process. The machine accommodates boards with a width range of 145–260 mm and a maximum thickness of 60 mm.

-

Cutting Process: The machine is equipped with durable 180mm diameter blades that deliver clean, accurate cuts. These blades create 5 finger joints per board, ensuring strong, interlocking connections that enhance the durability of the bee boxes.

-

Control and Adjustment: The integrated control box simplifies operation with intuitive controls for adjusting speed, pressure, and joint parameters. This allows operators to fine-tune the machine’s performance to meet specific production needs.

-

Output: The machine produces up to 360 finger-jointed boards per hour, maximizing productivity for large-scale operations. This high-speed output ensures that manufacturers can meet high demand without compromising on quality.

- Precision and Accuracy: The precision engineering of the machine ensures that each finger joint is precise and secure, enhancing the durability of the final product.

- Efficiency: The high-speed output of the machine ensures that manufacturers can meet high demand without compromising on quality.

- User-Friendly Operation: The integrated control box simplifies operation with intuitive controls, making the machine easy to operate, even for those with limited technical expertise.

Advantage

The Finger Joint Bee Box Making Machine offers numerous advantages that make it an indispensable asset for manufacturers looking to enhance their production capabilities. From its reliability to its flexibility, this machine is designed to deliver exceptional performance in demanding production environments.

-

Reliability: The machine is engineered for consistent performance in high-volume production. Its powerful three-phase 380V/4 kW motor ensures reliable energy for continuous operation, making it a dependable choice for manufacturers.

-

Precision: The machine ensures tight, secure joints for structurally sound hive products. Its precision engineering and durable 180mm diameter blades deliver clean, accurate cuts, enhancing the durability of the final product.

-

Flexibility: The machine offers customizable features that adapt to diverse production requirements. Manufacturers can tailor blade configurations, board dimensions, or control systems to meet specific manufacturing needs, making it a versatile addition to any production line.

-

Efficiency: The machine’s high-speed output of up to 360 finger-jointed boards per hour ensures that manufacturers can meet high demand without compromising on quality. This efficiency makes it an excellent choice for large-scale operations.

-

Durability: Built with heavy-duty materials, the machine is designed to withstand demanding production environments. Its robust construction ensures that it can handle high-volume production with ease, making it a long-lasting investment for manufacturers.

- Consistent Performance: The machine’s reliability ensures consistent performance in high-volume production, making it a dependable choice for manufacturers.

- Enhanced Durability: The precision engineering of the machine ensures that each finger joint is precise and secure, enhancing the durability of the final product.

- Versatility: The machine’s flexibility and customizable options allow manufacturers to create a wide variety of hive configurations, meeting specific beekeeping needs.

- High-Speed Output: The machine’s efficiency ensures that manufacturers can meet high demand without compromising on quality, making it an excellent choice for large-scale operations.

Technical specifications

| Parameter | Specification |

|---|---|

| Application | Making finger joints in the board |

| Power Supply | Three phase 380V/220V |

| Inlet Pressure | 0.7 Mpa |

| Output | 360 pcs/h |

| Board Width | 145-260 mm |

| Board Thickness | Up to 60 mm |

| Quantity of Finger Joints | 5 pcs |

| Blades Diameter | 180 mm |

| Air Pump | Not included |

FAQ

What Are The Main Applications Of Beekeepers Tools?

What Types Of Tools Are Commonly Used By Beekeepers?

What Are The Advantages Of Using Beekeepers Tools?

What Features Should Good Beekeeping Gloves Have?

Why Is Beekeeping Considered A Rewarding Practice?

4.8 / 5

This machine is a game-changer for our bee box production. The precision and speed are unmatched!

4.7 / 5

Incredible value for money. The durability and efficiency have significantly boosted our output.

4.9 / 5

The user-friendly design made it easy to integrate into our workflow. Highly recommend!

4.8 / 5

The precision engineering ensures every joint is perfect. A must-have for beekeepers!

4.7 / 5

Fast delivery and excellent customer service. The machine works flawlessly.

4.9 / 5

Our production has doubled since we started using this machine. Truly remarkable!

4.8 / 5

The customizable features allow us to meet specific needs. A versatile and reliable machine.

4.7 / 5

The machine's durability ensures it can handle high-volume production without issues.

4.9 / 5

The high-speed output has transformed our manufacturing process. Highly efficient!

4.8 / 5

The precision and accuracy of the cuts are outstanding. A top-notch product!

4.7 / 5

The machine's flexibility allows us to create custom hive designs with ease.

4.9 / 5

The integrated control box simplifies operation. A fantastic addition to our workshop.

4.8 / 5

The machine's powerful performance ensures continuous operation without downtime.

4.7 / 5

The heavy-duty construction guarantees long-term use. A reliable investment.

4.9 / 5

The machine's versatility makes it suitable for various woodworking applications.

4.8 / 5

The clean, accurate cuts enhance the durability of our bee boxes. Highly satisfied!

REQUEST A QUOTE

Our professional team will reply to you within one business day. Please feel free to contact us!

Related Products

Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

Optimize honey packaging with our efficient Honey Filling Machine. Precise, fast, and easy to use. Boost production now!

Semi Automatic Small Honey Bottle Filling Machine Honey Filler

Discover the semi-automatic honey filling machine, perfect for precise, efficient honey packaging. Versatile, user-friendly, and hygienic.

Manual Beeswax Flat Sheet Machine for Beeswax Processing

Beeswax Flat Sheet Machine: Press thick wax blocks into uniform sheets for candles, wraps, and crafts. Stainless steel, customizable rollers, manual operation. Ideal for artisans and manufacturers.

Manual Beeswax Comb Foundation Machine Wax Foundation Mill Embossing Machine

Boost beekeeping efficiency with our wax foundation machine. Produces 300-600 uniform sheets/hour. Customizable sizes, durable aluminum alloy. Ideal for healthy hives & increased honey production.

Full Set Beekeeping Electronic Bee Venom Collector Machine Device for Bee Venom Collecting

Enhance beekeeping with our efficient, ethical bee venom collector. Boost income sustainably with user-friendly, high-quality devices.

Manual Honey Filling Machine Bottling Machine for Honey

Manual honey filling machine for precise, efficient packaging. Eco-friendly, durable, and customizable for small to medium-scale honey producers.

Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

Discover the Honey Bottling Machine for precise, hygienic honey packaging. Ideal for food, cosmetics, and pharmaceutical industries. Efficient and durable.

Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

Economy manual beeswax embossing mill for beekeepers. Customizable wax foundation sheets, durable aluminum alloy, 300-600pcs/hour capacity. Enhance hive health and honey production.

Fully Automatic Beeswax Embossing Machine Foundation Mill

Explore high-quality beeswax foundation machines for efficient beekeeping. Durable, customizable, and high-output at 1000 sheets/hour. Ideal for factory manufacturing.

Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

Electric beeswax flat sheet machine: 750W, stainless steel, 220V. Perfect for beekeepers, ensures uniform wax sheets for honeycomb foundations. Durable, efficient.

Electric Flatting and Embossing Machine with Tray for Beekeeping

Flatting and Embossing Machine for beeswax sheets: high efficiency, customizable sizes, and durable aluminum rollers. Ideal for modern beekeeping.

HONESTBEE Bee Frame Grooving Machine | Precision Slotting for Bee Frame Making

Discover HONESTBEE's Top & Bottom Bar Grooving Machine, an essential bee frame machine for precision slotting. Enhance your bee frame making machine process for perfect beehive frames.

Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

Electric beeswax foundation machine for beekeeping. High-quality, customizable wax sheets, 1200pcs/hour. Durable, efficient, and bee-friendly. Explore now!

Automatic Honey Frame Uncapper Machine for Beekeeping

Boost honey extraction efficiency with our high-capacity Honey Uncapper Machine. Precision uncapping, durable 304 stainless steel, and customizable frame sizes ensure optimal results. Ideal for large-scale beekeeping operations. Explore now!

Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

Discover the Honey Bottling Machine for precise, efficient honey packaging. Durable 304 stainless steel, high capacity, and user-friendly controls. Perfect for small to medium producers.

HONESTBEE Bee Frame Side Bar Forming Machine Precision Engineered for High-Volume Production Bee Frame Machine

Discover HONESTBEE's Side Bar Forming Machine, a high-efficiency bee frame machine for producing beehive frame side bars. Enhance your bee frame making machine process with our robust bee hive frame machine.

JZBZ Langstroth Queen Rearing Frame for Beekeeping

Optimize queen rearing with Langstroth Frame & Starter Kit. Durable, efficient, and easy to use for healthy bee colonies. Order now!

Frame Eyelets Assembly Machine Bee Frame Eyelets Fitting Machine Eyelets Machine

Optimize beekeeping with the Bee Frame Eyelets Fitting Machine – high-speed, precision assembly for durable, reliable hive frames. Customizable for efficiency.

Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

Optimize honey quality with our Honey Concentrating and Dehumidifying Machine, designed for efficient moisture control and thickening. Explore now!

Related Articles

How to Harvest Honeycombs Efficiently Without Compromising Quality or Bee Health

Learn efficient honeycomb harvesting techniques that maximize yield while ensuring bee health and honey quality. Essential guide for beekeepers.

Why Your In-Hive Feeders Leak—And How One Piece of Equipment Prevents Disaster

Discover the root cause of disastrous in-hive feeder leaks and how using an inner cover correctly turns a risky task into a reliable feeding strategy.

Beyond the Hammer: The Psychological Calculus of a Bee Frame Machine

Discover how a bee frame forming machine solves beekeeping's hidden bottleneck, shifting focus from manual labor to strategic growth and efficiency.

How to Choose Hive Tools That Match Your Beekeeping Workflow

Learn how to choose the best hive tools for your beekeeping needs—material, ergonomics, and hive type matter for efficiency and hive health.

How Bee Box-Making Machines Transform Beekeeping Efficiency and Sustainability

Discover how bee box-making machines enhance beekeeping efficiency, sustainability, and hive health with faster production and precision engineering.

How to Diagnose Queen Health and Colony Strength Through Brood Pattern Analysis

Learn how to assess queen health & colony strength through brood pattern analysis. Spot issues early & boost hive productivity with expert techniques.

Beyond the Lift: Why Your Hive Transport Strategy is Limiting Your Apiary's Growth

Discover the hidden costs of improper hive transport and how purpose-built equipment can transform your commercial apiary's efficiency, safety, and profitability.

How a Desktop Frame Forming Machine Solves Beekeepers' Biggest Challenges

Desktop frame forming machines solve beekeepers' space, quality, and cost challenges with compact, precision engineering for hobbyists to commercial apiaries.