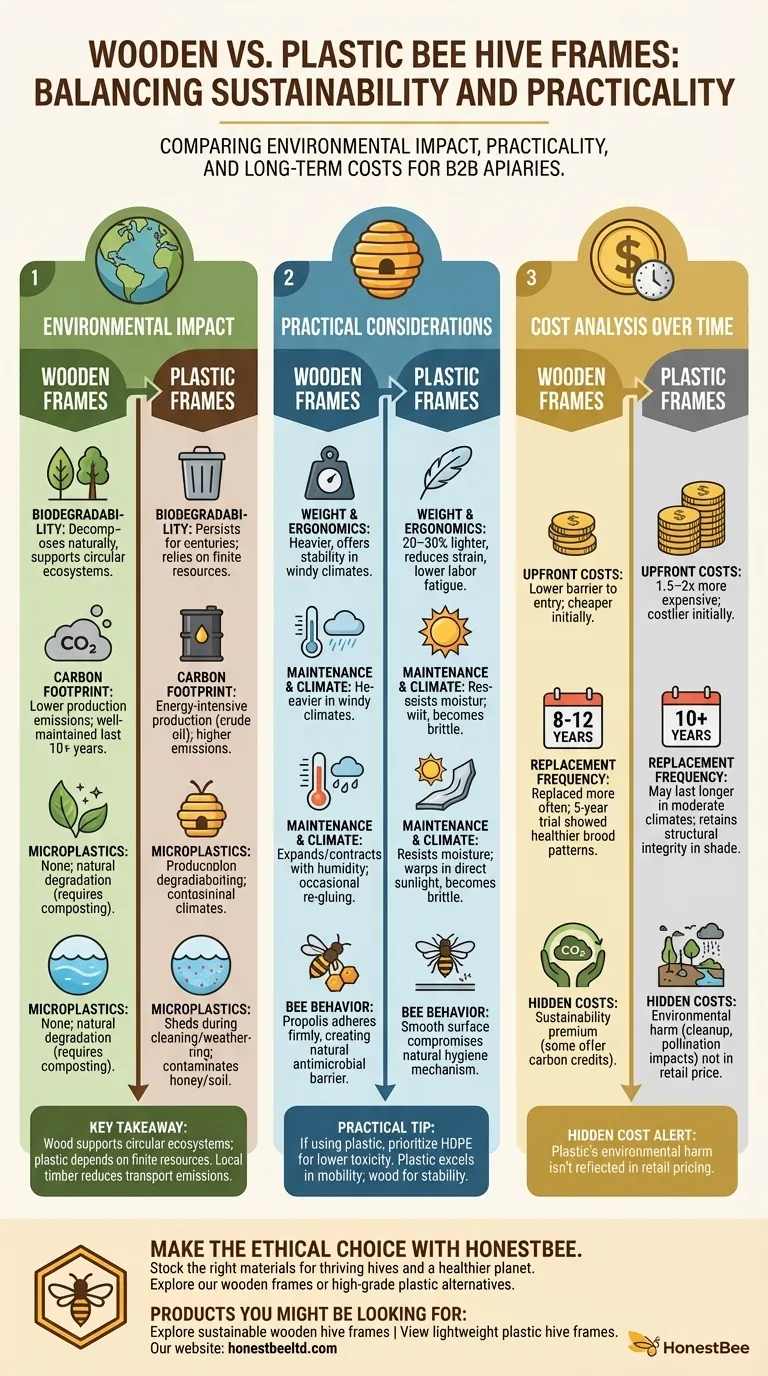

Choosing the right hive frame material isn’t just about cost—it’s a decision that impacts your bees’ health, your operational efficiency, and the environment. This guide compares wooden and plastic frames across three critical dimensions: environmental impact, practical beekeeping considerations, and long-term costs.

Environmental Impact of Hive Frame Materials

Biodegradability and Sourcing Ethics

Wooden frames, typically made from sustainably harvested pine or cedar, decompose naturally at the end of their lifespan. In contrast, plastic frames rely on petroleum-based polymers that persist in landfills for centuries. While some manufacturers use recycled plastics, the extraction and processing of virgin materials still contribute to habitat destruction.

Key takeaway: Wood supports circular ecosystems; plastic depends on finite resources.

Carbon Footprint and Production Realities

Wood production emits less carbon than plastic manufacturing, which involves energy-intensive processes like cracking crude oil. However, wooden frames may require more frequent replacement, potentially offsetting their initial advantage. Research shows that well-maintained wooden frames can last over a decade, narrowing this gap.

Consider: Local timber sourcing reduces transport emissions—ask suppliers about origin transparency.

Microplastic Risks and End-of-Life Disposal

Plastic frames shed microplastics during cleaning and weathering, which can contaminate honey and soil. A 2022 study found microplastics in 75% of commercial hive products sampled. Wooden frames avoid this entirely, but their natural degradation requires proper composting to avoid attracting pests.

Practical tip: If using plastic, prioritize high-density polyethylene (HDPE) over PVC for lower toxicity.

Practical Considerations for Beekeepers

Weight and Ergonomics in Large-Scale Operations

Plastic frames are 20–30% lighter than wood, reducing strain during hive inspections. For commercial apiaries managing thousands of hives, this ergonomic benefit can significantly lower labor fatigue. However, lightweight frames may be prone to wind displacement in open fields.

Tradeoff: Plastic excels in mobility; wood offers stability in windy climates.

Maintenance Demands Across Climates

Wood expands and contracts with humidity, requiring occasional re-gluing or tightening. Plastic resists moisture but can warp in direct sunlight, leading to misaligned comb. Beekeepers in hot regions report plastic frames becoming brittle after 5–7 years.

Bee behavior insight: Propolis adheres more firmly to rough wooden surfaces, creating a natural antimicrobial barrier. Plastic’s smooth surface may compromise this hygiene mechanism.

Cost Analysis Over Time

Upfront Costs vs. Replacement Frequency

Plastic frames cost 1.5–2x more initially but may last longer in moderate climates. Wooden frames are cheaper upfront but need replacement every 8–12 years. For budget-conscious beekeepers, wood’s lower barrier to entry is appealing.

Hidden cost alert: Plastic’s environmental harm (e.g., cleanup costs, pollination impacts) isn’t reflected in retail pricing.

Weather Resistance and Longevity Case Studies

A 5-year apiary trial found:

- Plastic frames in shaded areas retained structural integrity

- Wooden frames in rainy climates required 30% more maintenance but fostered healthier brood patterns

Sustainability premium: Some distributors offer carbon credits for wooden frame purchases.

Make the Ethical Choice with HONESTBEE

Whether you prioritize durability or sustainability, HONESTBEE’s wholesale beekeeping supplies help commercial apiaries and distributors stock the right materials. Explore our wooden frames or high-grade plastic alternatives—each designed to support thriving hives and a healthier planet.

Next step: Audit your current frames’ lifecycle costs. How many replacements could you avoid with climate-appropriate materials?

Products You Might Be Looking For:

Explore sustainable wooden hive frames

View lightweight plastic hive frames

Visual Guide

Related Products

- Plastic Bee Frame Beekeeping Hive Frames for Wholesale

- HONESTBEE Wired and Assembled Wooden Bee Frames Foundation for a Thriving Hive

- Assembled Wooden Bee Frames with Plastic Foundation for Durability and Convenience by HONESTBEE

- Assembled Wooden Bee Frames with Beeswax Foundation Ready to Use by HONESTBEE

- Heavy-Duty Stainless Steel Clip-On Frame Perch

Related Articles

- How to Transition Hive Frames Safely Without Disrupting Colony Health

- How Honey Frames Naturally Manage Queen Bees Without Compromising Colony Health

- How Specialized Frames Revolutionize Queen Rearing Success

- How Beehive Frame Making Machines Enhance Apiary Productivity and Hive Longevity

- Beyond the Scraper: The Invisible War on a Beehive Frame