In most cases, yes. A standard, universal bucket opener is designed to work on the vast majority of common plastic pails, including standard 3.5, 5, and 7-gallon buckets. These tools are specifically engineered to pry open the tightly sealed lids common in industrial and food-grade containers.

The core issue isn't the plastic itself, but the type of seal the lid creates. Bucket openers are simply leverage tools designed to defeat the common airtight, locking-tab seal found on most pails.

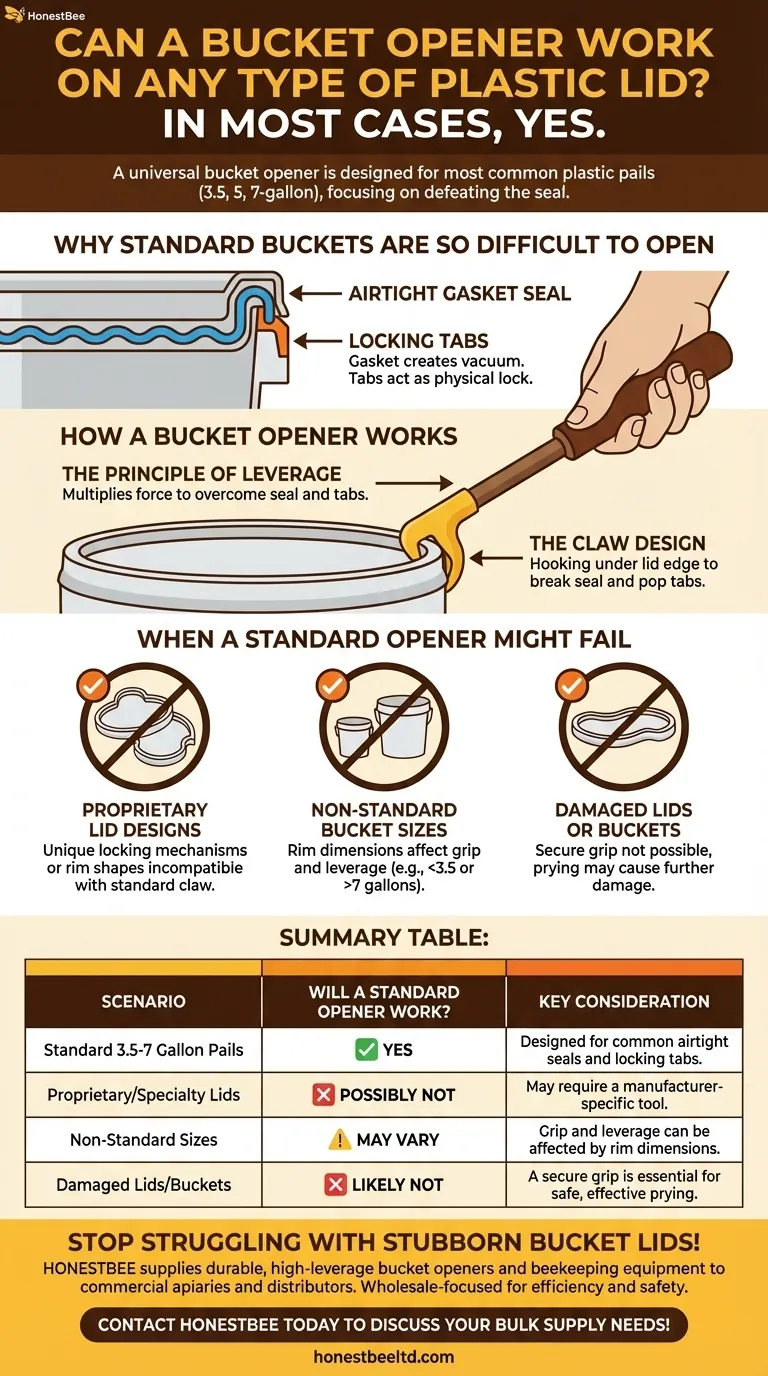

Why Standard Buckets Are So Difficult to Open

To understand the tool, you must first understand the problem. The difficulty in opening a new bucket is a feature, not a flaw, designed to protect the contents.

The Airtight Gasket Seal

Most new pails use a rubber or plastic gasket inside the lid's channel. When the lid is pressed on, this gasket creates an airtight and watertight seal.

This seal prevents contamination and spillage, but it also creates a slight vacuum, holding the lid down with significant force.

The Locking Tabs

Around the perimeter of the lid are small plastic tabs or segments that snap securely under the bucket's rim.

These tabs act as a physical lock, preventing the lid from vibrating loose or being opened accidentally. They are the primary obstacle the opener is designed to overcome.

How a Bucket Opener Works

A bucket opener is a simple machine that multiplies your force, allowing you to easily overcome the seal and locking tabs without damaging the container.

The Principle of Leverage

The long handle of the opener acts as a lever. It allows you to apply a small amount of downward force that translates into a much greater upward force on the edge of the lid.

This is the same principle that makes a crowbar effective.

The Claw Design

The small "claw" or "tooth" at the end of the tool is designed to hook securely under the lid's edge.

As you press down on the handle, this claw pries one section of the lid upward, breaking the seal and popping the locking tabs free in that area. You then work your way around the rim, section by section.

When a Standard Opener Might Fail

While universal openers are highly effective, they are not infallible. Certain situations can present a challenge.

Proprietary Lid Designs

Some manufacturers use unique, proprietary lid and bucket designs, especially for specialty chemicals or products.

These systems may have different locking mechanisms or rim shapes that are incompatible with a standard opener's claw.

Non-Standard Bucket Sizes

Though less common, buckets that are significantly smaller (e.g., 1-2 gallons) or larger than the standard 3.5-7 gallon range may have different rim dimensions.

This can prevent the tool from getting the proper grip and leverage needed to work effectively.

Damaged Lids or Buckets

If the rim of the bucket or the edge of the lid is already damaged or warped, the opener's claw may not be able to get a secure grip.

In these cases, forcing the issue can cause further damage to the plastic, making the problem worse.

Making the Right Choice for Your Goal

To ensure you have the right tool, consider the type of buckets you will be handling.

- If your primary focus is on common household or hardware store buckets: A standard, universal bucket opener is the correct and most efficient tool for the job.

- If you are dealing with specialized industrial or commercial containers: First, inspect the lid for any unique features and confirm if the manufacturer recommends a specific opening tool.

Ultimately, a bucket opener is an essential tool for anyone who frequently works with sealed pails, saving time and preventing damage to both the container and your hands.

Summary Table:

| Scenario | Will a Standard Opener Work? | Key Consideration |

|---|---|---|

| Standard 3.5-7 Gallon Pails | ✅ Yes | Designed for common airtight seals and locking tabs. |

| Proprietary/Specialty Lids | ❌ Possibly Not | May require a manufacturer-specific tool. |

| Non-Standard Sizes | ⚠️ May Vary | Grip and leverage can be affected by rim dimensions. |

| Damaged Lids/Buckets | ❌ Likely Not | A secure grip is essential for safe, effective prying. |

Stop struggling with stubborn bucket lids! HONESTBEE supplies durable, high-leverage bucket openers and a full range of beekeeping supplies and equipment to commercial apiaries and distributors. Our wholesale-focused operations ensure you get the reliable tools you need to work efficiently and safely.

Contact HONESTBEE today to discuss your bulk supply needs and streamline your operation!

Visual Guide

Related Products

- Food Grade Plastic Honey Bucket Pail for Beekeeping

- Hexagonal Glass Honey Jar with Wooden Lid Integrated Dipper Elegant Functional Storage

- Classic Drum Shaped Glass Honey Jar with Airtight Lid

- Classic Beehive Honey Bottle Jar with Squeeze Dispenser Lid

- Ergonomic Squeezable Honey Bottle with Precision Twist Nozzle Cap

People Also Ask

- Is it advisable to use a screwdriver instead of a bucket opener? Avoid Injury and Container Damage

- Why are bucket openers important for efficiency and safety? Boost Speed & Protect Your Products

- What are the benefits of using a bucket opener? Boost Safety & Efficiency in Your Operations

- What are some common uses for bucket openers? Essential for Safety & Efficiency in Commercial Operations

- What are the main benefits of using a bucket opener? Enhancing Safety and Preservation

- What are the best practices for using a bucket opener? Open Buckets Safely & Efficiently

- What is a bucket opener and what is its primary function? Open Pails Safely & Preserve Seals

- What is a bucket opener? The Essential Tool for Safe and Efficient Lid Removal