The short answer is control. Beekeepers customize honey quality by selecting different filter mesh sizes within their filtering machine. This single variable allows them to precisely determine what is removed from the honey, enabling them to produce everything from a minimally-filtered, rustic product to a perfectly clear, liquid-gold honey suitable for retail shelves.

A honey filtering machine is not simply a cleaning device; it is a strategic tool. It gives the beekeeper direct control over the honey’s final character—its clarity, texture, and shelf life—by selectively removing or retaining particles like wax, debris, and pollen.

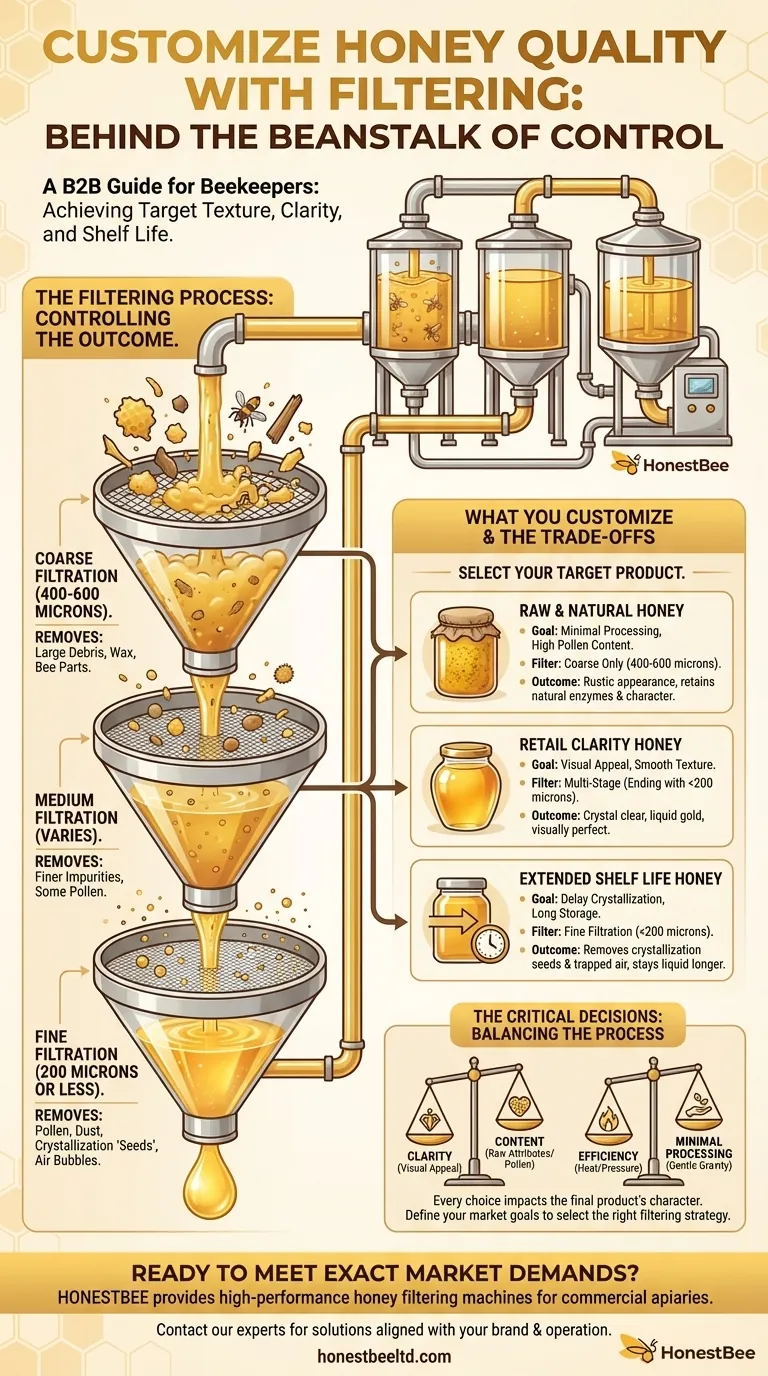

The Core Mechanism: Controlling Filtration Levels

A honey filtering machine's primary function is to pass honey through a series of screens or filters. The customization comes from the beekeeper's choice of which filters to use.

The Role of Filter Mesh Size

The mesh size of a filter determines the size of the particles that are allowed to pass through. A larger mesh (a lower micron number) will only catch large debris, while a progressively finer mesh (a higher micron number) will remove smaller and smaller particles.

From Coarse to Fine Filtration

Most processes involve multiple stages. Honey is first passed through a coarse filter to remove large impurities like wax cappings and bee parts. It can then be passed through finer filters to achieve the desired level of clarity.

The Impact on Pollen Content

This is the most critical aspect of customization. Fine filters will remove most, if not all, of the naturally occurring pollen grains in honey. Some consumers seek out honey with high pollen content for its perceived health benefits, while others prefer the visual appeal of perfectly clear honey.

What a Filtering Machine Actually Removes

Understanding what is being filtered out is key to understanding how you are shaping the final product. The machine targets several specific elements.

Physical Debris

This is the most basic level of filtration. It removes unwanted contaminants that get mixed in during extraction, such as wax particles, wood splinters from the hive body, and bee parts.

Particulates Affecting Clarity

The primary cause of cloudy honey is suspended microscopic particles. A filtering machine effectively removes fine dust and pollen grains, resulting in a clearer, more visually appealing product.

Elements That Accelerate Crystallization

Fine particles and even existing sugar crystals can act as "seeds" that trigger the crystallization process. By removing these, filtration helps keep the honey in a liquid state for longer, extending its shelf life on the shelf.

Trapped Air Bubbles

The process can also help remove tiny air bubbles that are incorporated during extraction. This leads to a smoother texture and enhances the honey's glass-like appearance in a jar.

Understanding the Trade-offs

Customization is about making deliberate choices, and each choice has an implication. There is no single "best" way to filter honey; there is only the best way for your specific goal.

Clarity vs. "Raw" Honey Attributes

The biggest trade-off is between clarity and content. By filtering out pollen and other microscopic solids to achieve a pristine appearance, you are also removing elements that many consumers associate with "raw" or "unprocessed" honey.

The Use of Heat

Some filtering systems gently heat the honey to lower its viscosity, making it flow through the fine filters more easily. While this improves efficiency, excessive heat can degrade delicate enzymes and aromas. A skilled beekeeper uses just enough heat to enable filtration without "cooking" the honey.

Efficiency vs. Minimal Processing

Aggressive, fine filtration using pressure systems is highly efficient and produces a very consistent product. However, a minimalist approach using only coarse gravity filtration is slower but preserves more of the honey's natural state.

Making the Right Choice for Your Goal

Your filtration strategy should be directly aligned with your target market and brand identity.

- If your primary focus is a "raw" or "natural" product: Use only a coarse mesh filter (e.g., 400-600 microns) to remove large debris while intentionally retaining all pollen and fine particles.

- If your primary focus is maximum clarity for retail: Employ a multi-stage filtration process, ending with a fine mesh filter (e.g., 200 microns or less) to remove all particulates that cause cloudiness.

- If your primary focus is extending shelf life: Ensure your process removes fine crystallization "seeds," which typically requires filtration down to a fine level.

Ultimately, a honey filtering machine empowers you to define the final product and deliver exactly what your customers value most.

Summary Table:

| Filtration Goal | Recommended Filter Micron Size | Key Outcome |

|---|---|---|

| Raw/Natural Honey | 400-600 microns | Removes large debris, retains pollen and natural character. |

| Maximum Clarity for Retail | 200 microns or less | Removes all particulates for a clear, visually appealing product. |

| Extended Shelf Life | Fine filtration (e.g., 200 microns) | Removes crystallization seeds to keep honey liquid longer. |

Ready to customize your honey production and meet exact market demands? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-performance, wholesale-focused honey filtering machines. Our equipment gives you precise control over filtration levels to produce everything from rustic raw honey to perfectly clear retail products. Contact our experts today to find the perfect filtering solution for your operation and brand.

Visual Guide

Related Products

- Stainless Steel Triangle Support Honey Strainer and Filters

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Stainless Steel Manual 8 Frame Radial Honey Extractor Machine for Beehives

- Professional 4 Frame Self Reversing Electric Honey Extractor for Beekeeping

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

People Also Ask

- How does using a honey filtering machine help in minimizing contamination? Ensure Pure, High-Quality Honey Standards

- What methods can be used to strain raw honey? Expert Techniques for Pure, Clean Honey Harvests

- What function does honey filtration and clarification equipment serve? Enhance Purity and Value in Your Production

- What is the purpose of using a standard grading sieve before filling propolis powder? Optimize Capsule Quality

- What role does honey filtering equipment play in meeting commercial quality standards? Upgrade Your Honey for Export

- What is the function of a honey filter machine? Elevate Purity and Commercial Quality for Your Apiary

- What purpose do honey settling and filtration tanks serve? Boost Purity and Market Value in Honey Processing

- What role does industrial-grade filtration equipment play in the production of raw honey? Enhance Purity and Quality