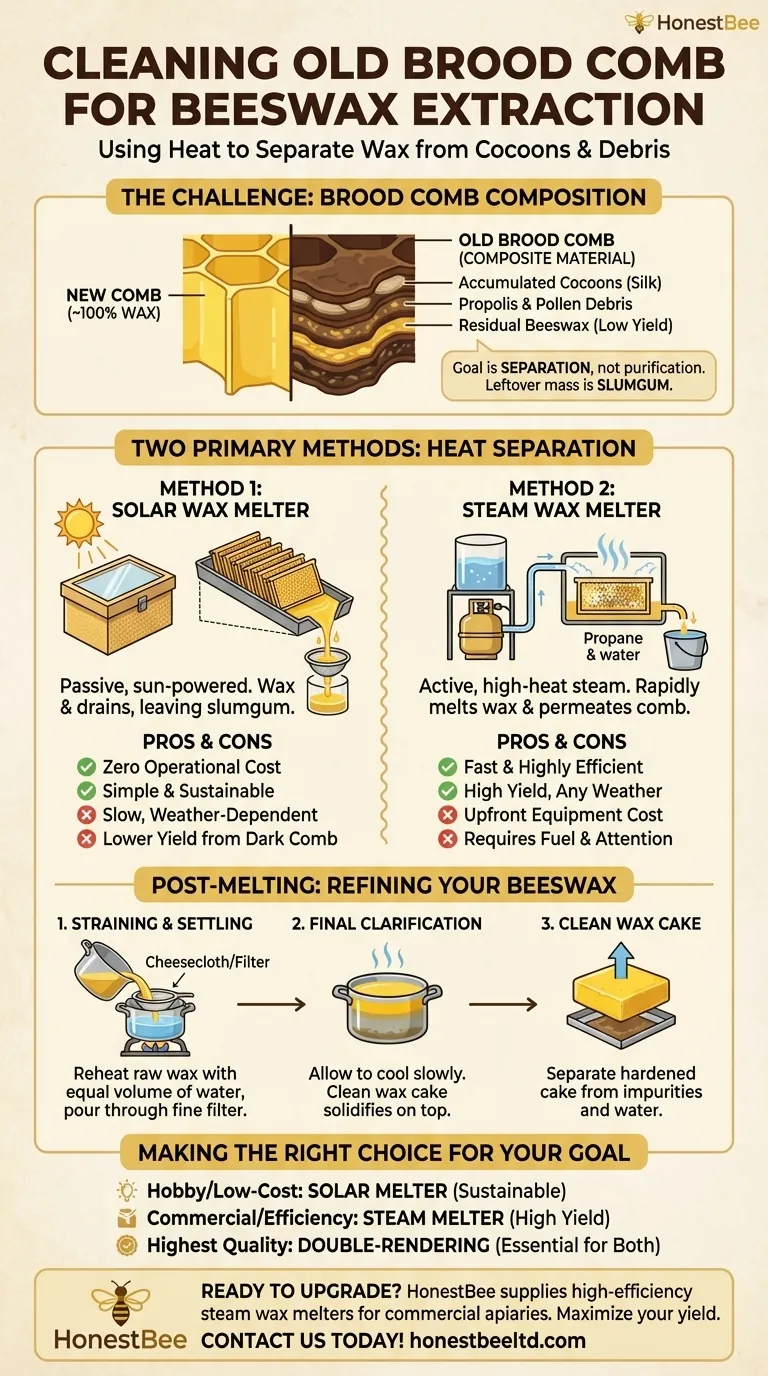

To extract beeswax from old brood comb, the most effective methods use heat to separate the wax from the accumulated cocoons and debris. The two primary pieces of equipment for this task are solar wax melters, which use the power of the sun, and steam wax melters, which use boiling water to generate steam. Both methods are designed to melt the wax, allowing it to drain away from the non-wax material.

The core challenge with old brood comb isn't just cleaning it, but accepting its composition. It contains far more debris (pupal cocoons, propolis, waste) than actual wax, so the goal is separation, not purification, in the first step.

Why Brood Comb is a Special Challenge

Unlike the nearly pure wax from honey cappings, old brood comb is a composite material. Understanding its makeup is key to setting realistic expectations for your beeswax yield.

The Anatomy of Old Brood Comb

Each time a bee develops from a larva to an adult in a cell, it leaves behind a thin silk cocoon. Over many generations, these cocoons build up, layer by layer.

The bees also track in propolis and pollen, which get integrated into the comb structure. This accumulation is what turns the comb from bright yellow to dark brown or black.

The leftover mass of cocoons, propolis, and other debris after the wax has been melted out is called slumgum. It is a dense, fibrous material with very little value.

Setting Realistic Wax Yields

A new, deep frame of foundation and drawn comb contains about a quarter-pound of pure wax. An old, black brood comb from that same frame might yield only half that amount, or even less.

The older and darker the comb, the lower the percentage of recoverable wax. Expect to process a large volume of old comb to get a modest amount of beeswax.

The Two Methods for Wax Extraction

Both methods rely on the same principle: wax melts at a relatively low temperature (around 145°F / 63°C), while the slumgum does not. Heat allows the liquid wax to be separated.

Method 1: The Solar Wax Melter

A solar wax melter is essentially a well-insulated box with a dark interior and a glass or polycarbonate lid, designed to trap the sun's heat.

Inside, combs are placed on a sloped metal pan. As the sun heats the box, the wax melts, runs down the pan, and drips through a filter or screen into a collection container. The slumgum is left behind on the pan.

Method 2: The Steam Wax Melter

A steam wax melter uses an external heat source (like a propane burner) to boil a reservoir of water, piping the resulting steam into a chamber holding the old combs.

The hot steam permeates the combs, rapidly melting the wax. The melted wax and condensed steam then drain out of the chamber into a collection bucket. This method is much faster and more aggressive than a solar melter.

Understanding the Trade-offs

Neither method is universally superior; the best choice depends on your scale, climate, and goals.

Solar Melter: Pros & Cons

The primary advantage of a solar melter is its zero operational cost and simplicity. It uses free energy from the sun and operates passively.

However, it is slow and weather-dependent, requiring hot, sunny days to function effectively. It is also less efficient at extracting wax from the darkest combs, as the slumgum can absorb the liquid wax and prevent it from draining completely.

Steam Melter: Pros & Cons

A steam melter is fast and highly efficient, able to process large quantities of comb in any weather, day or night. It can extract more wax from very old comb compared to a solar melter.

The main downsides are the upfront cost of the equipment and the need for a fuel source like propane. It is an active process that requires your attention during operation.

Post-Melting: Refining Your Beeswax

The wax collected from a first-pass melt will still contain fine debris and sediment. To get clean, usable wax blocks, a second rendering step is required.

Straining and Settling

The raw, melted wax is typically poured through a finer filter, like cheesecloth or a paint strainer, into a pot. It is then gently reheated with an equal volume of water.

Final Clarification

Once the wax-water mixture is fully melted, it is removed from the heat and allowed to cool very slowly. As it cools, the clean wax solidifies into a cake on top, while the dirt and impurities settle into the water below. Once hard, the wax cake can be easily separated.

Making the Right Choice for Your Goal

Your beekeeping operation's size and your available time will guide your decision.

- If your primary focus is low-cost processing for a hobby apiary: A DIY or commercial solar wax melter is an excellent, sustainable choice for a small number of combs.

- If your primary focus is efficiency for a larger or sideline operation: A steam wax melter is a worthwhile investment that will save you significant time and increase your overall yield.

- If your primary focus is achieving the highest quality wax: Regardless of the melting method, master the double-rendering process to separate the clean wax from the final impurities.

Salvaging wax from old combs is a rewarding way to reclaim a valuable resource from your hives.

Summary Table:

| Method | Best For | Pros | Cons |

|---|---|---|---|

| Solar Wax Melter | Hobby apiaries, low-cost processing | Zero operational cost, uses solar energy | Slow, weather-dependent, lower yield from dark comb |

| Steam Wax Melter | Larger operations, efficiency | Fast, high yield, works in any weather | Higher upfront cost, requires fuel source |

Ready to upgrade your wax extraction process? As HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with high-efficiency steam wax melters and other essential beekeeping supplies. Our wholesale-focused operations ensure you get the best equipment to maximize your beeswax yield and operational efficiency. Contact us today to discuss your needs!

Visual Guide

Related Products

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Professional Thermostatic Conical Honey Melter

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

People Also Ask

- How can the beeswax cappings from honey extraction be processed and reused? Transform Waste into High-Value Gold

- What is the specific function of applying melted natural beeswax? Boost Your Hive Occupancy with Biological Lures

- What role does efficient beeswax extraction and purification equipment play in diversification? Unlock New Markets

- What are the advantages of integrated electric heating tubes compared to traditional steam heating? Boost Your Efficiency

- How do steam wax melting machines support the biological control of Varroa mites? Stop Parasite Spread and Recover Wax