To melt beeswax with a double boiler, you use a two-tiered system to provide gentle, indirect heat. Fill the bottom pot with water and bring it to a simmer, then place the beeswax in the upper, separate pot or bowl. The steam from the water below will melt the wax evenly and safely, without scorching it or creating a fire risk.

The core principle is not about melting the wax quickly, but melting it safely. A double boiler uses steam as a buffer, ensuring the temperature remains low and stable, which is critical for preserving the wax's quality and preventing it from reaching its dangerous flashpoint.

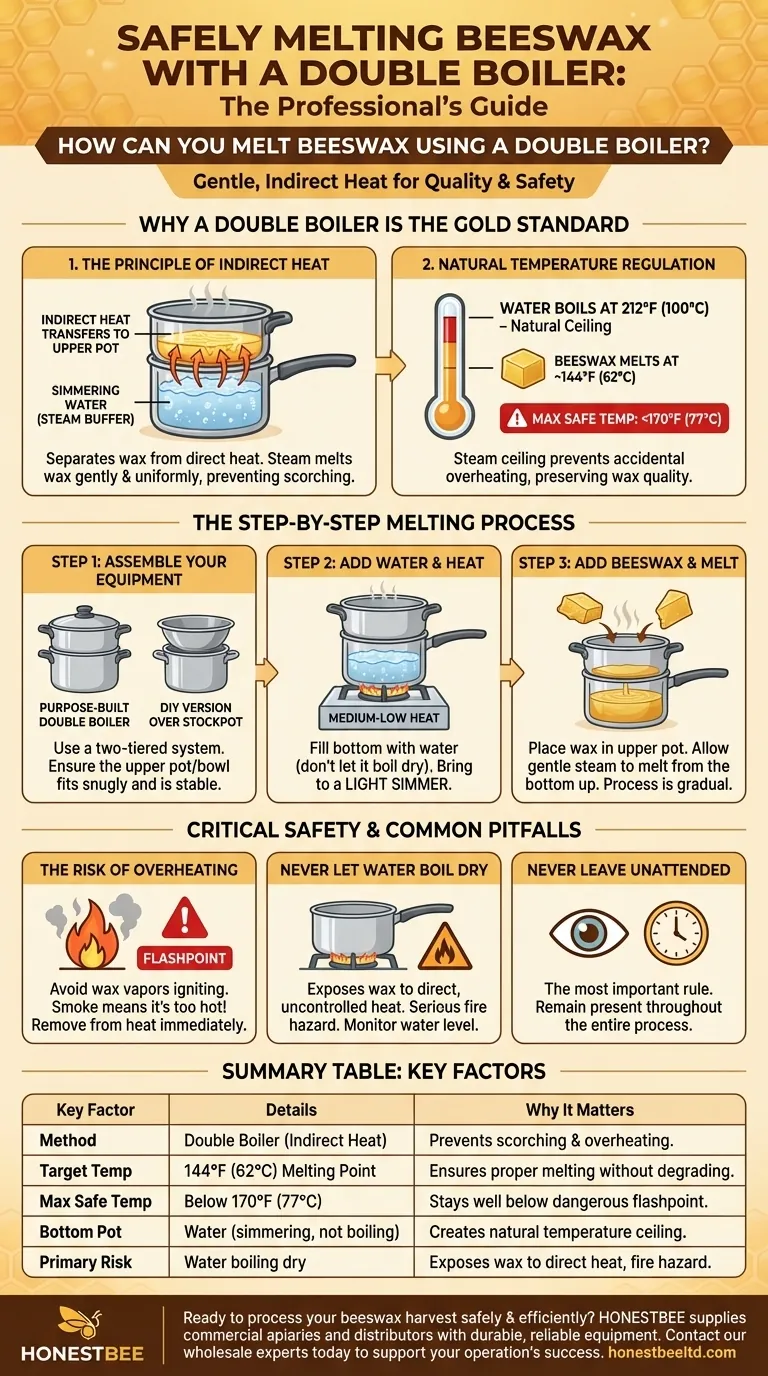

Why a Double Boiler is the Gold Standard

The choice of a double boiler is a deliberate one, rooted in the chemical properties of beeswax. It is a simple, effective tool for risk management.

The Principle of Indirect Heat

A double boiler works by separating the wax from the direct heat source. The bottom pot contains only water, which is heated to a simmer.

This simmering water produces steam, which then transfers its heat to the bottom of the upper pot. This process ensures the wax melts gently and uniformly, without developing hot spots that can scorch and discolor it.

Natural Temperature Regulation

Water boils at 212°F (100°C), creating a natural temperature ceiling for the melting process. Beeswax melts at around 144°F (62°C) and should not be heated beyond 170°F (77°C) to preserve its quality.

Because the steam cannot get significantly hotter than the boiling water, the double boiler method makes it much more difficult to accidentally overheat the wax.

The Step-by-Step Melting Process

Whether you have a dedicated double boiler or are making a temporary one, the process is straightforward.

1. Assemble Your Equipment

A purpose-built double boiler has two interlocking pots. You can easily create your own by placing a heat-safe metal or glass bowl over a larger stockpot.

Ensure the bowl fits snugly on the rim of the pot without touching the water below. It must be stable.

2. Add Water and Heat

Fill the bottom pot with a few inches of water. There should be enough to create steam without it boiling dry, but not so much that it touches the bottom of the upper container.

Place the pot on the stove and bring the water to a light simmer over medium-low heat. A rolling boil is unnecessary and can create too much steam or splash water.

3. Add Beeswax and Melt

Place your solid beeswax into the dry upper pot or bowl. As the steam heats the container, the wax will begin to melt from the bottom up.

The process is gradual. Allow the gentle heat to do its work without turning up the stove. Once the wax is fully liquid, it is ready.

Critical Safety and Common Pitfalls

Beeswax is flammable, and safety must be your primary concern. The double boiler method minimizes risks, but it does not eliminate them.

The Risk of Overheating

The primary danger is the flashpoint—the temperature at which the wax vapors can ignite if exposed to a flame. Using gentle, indirect heat is the best way to stay well below this temperature.

If you see or smell smoke, your wax is too hot. Immediately remove it from the heat.

Never Let the Water Boil Dry

The water in the bottom pot is your primary safety control. If it all evaporates, the upper pot will be exposed to direct, uncontrolled heat from the burner.

This can cause the wax temperature to rise rapidly, leading to scorching and creating a serious fire hazard. Keep an eye on the water level during longer melting sessions.

Never Leave Melting Wax Unattended

This is the most important rule. A situation can become dangerous in seconds. Always remain present and attentive throughout the entire melting process.

Making the Right Choice for Your Project

Your goal determines how you approach the process.

- If your primary focus is maximum safety and quality: Use a double boiler, keep the heat on medium-low, and monitor the wax with a thermometer to ensure it stays below 170°F (77°C).

- If your primary focus is small-batch crafting: A DIY double boiler using a saucepan and a metal bowl is perfectly sufficient and effective for projects like lip balms or lotions.

- If you are looking for an energy-free alternative: Consider a solar melter, which uses the sun's heat for an even gentler, though much slower, melting process.

Ultimately, mastering the double boiler method empowers you to handle beeswax safely and effectively for any project.

Summary Table:

| Key Factor | Details | Why It Matters |

|---|---|---|

| Method | Double Boiler (Indirect Heat) | Prevents scorching and overheating of wax. |

| Target Temperature | 144°F (62°C) Melting Point | Ensures wax melts properly without degrading. |

| Max Safe Temperature | Below 170°F (77°C) | Stays well below the dangerous flashpoint. |

| Bottom Pot Content | Water (simmering, not boiling) | Creates a natural temperature ceiling for safety. |

| Primary Risk | Water boiling dry | Exposes wax to direct heat, creating a fire hazard. |

Ready to process your beeswax harvest safely and efficiently?

As a beekeeper, you know that quality equipment is key to producing quality products. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the durable, reliable supplies needed for every step of the process—from hive to finished product.

Contact our wholesale experts today to discuss your equipment needs and learn how we can support your operation's success.

Visual Guide

Related Products

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Honey Tank Heater Drum Heating Blanket for Honey Barrel

People Also Ask

- Can I melt beeswax in a wax melter? The Key to Safe, High-Quality Results

- How can you monitor the temperature of beeswax as it melts? Ensure Quality & Safety with Precise Control

- What is the flash point of beeswax, and why is it important? Essential Safety Guide for Beekeepers

- What factors should be considered when choosing a wax melter? Optimize Your Beekeeping Efficiency

- How long does the wax melting process typically take? A Guide to Safe & Efficient Melting