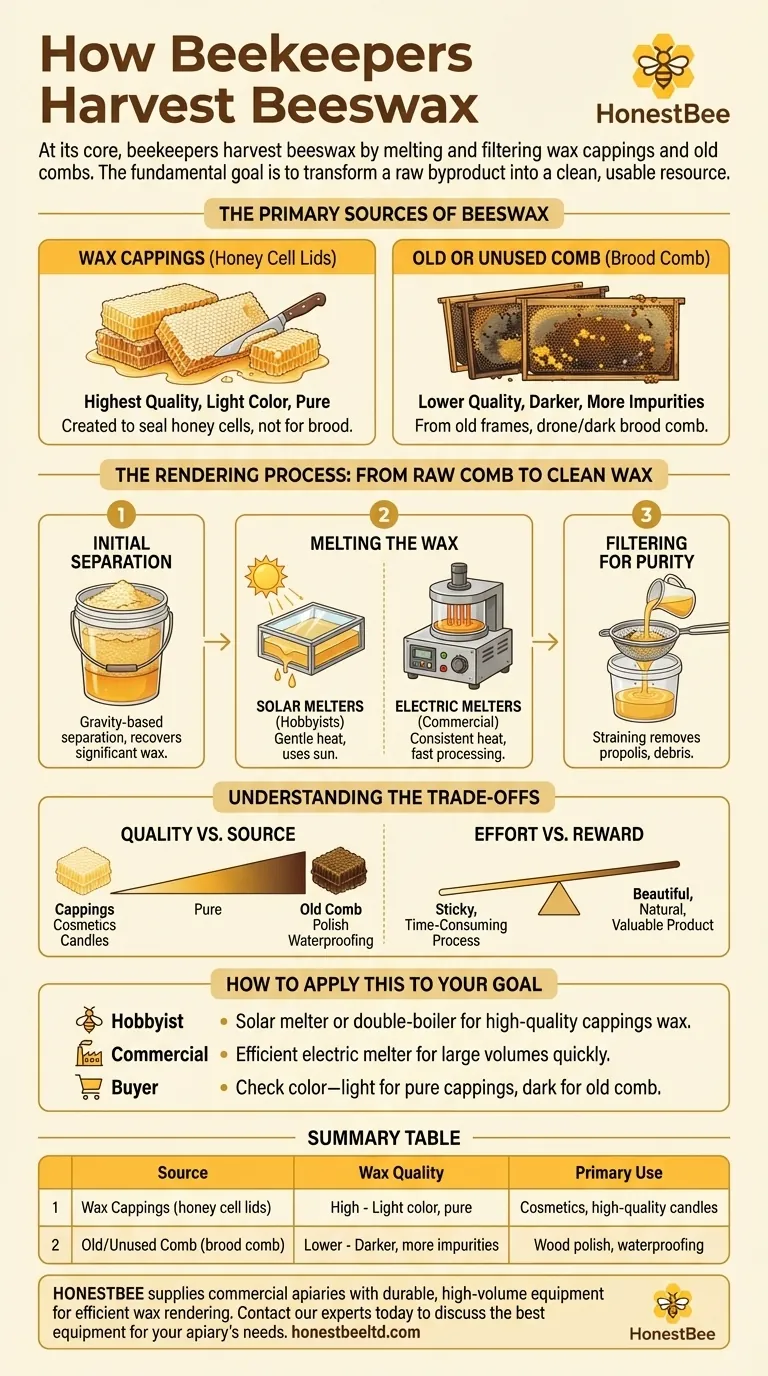

At its core, beekeepers harvest beeswax by melting and filtering the wax cappings and old combs that are removed from the hive during honey extraction or routine maintenance. This process, known as rendering, separates the pure wax from honey, cocoons, pollen, and other hive debris.

The fundamental goal of harvesting beeswax is to transform a raw byproduct of beekeeping into a clean, usable resource. This is achieved by melting the wax to separate it from impurities and then allowing it to cool into solid blocks.

The Primary Sources of Beeswax

Beeswax isn't just scraped from the hive walls. It is harvested from two specific structures built by the bees, each yielding wax of a different quality.

Wax Cappings

This is the highest quality beeswax you can get. Bees create fresh, clean wax lids to seal cells filled with ripened honey.

During honey harvesting, beekeepers slice these cappings off the frames. This wax is prized for its light color and purity because it has not been used for raising young bees (brood).

Old or Unused Comb

Beekeepers also harvest beeswax from old frames that are being taken out of circulation. This can include drone comb or dark brood comb.

This wax is often darker and contains more impurities, such as larval cocoons, pollen, and propolis. It requires a more thorough rendering process to become clean.

The Rendering Process: From Raw Comb to Clean Wax

Rendering is the multi-step method of melting and purifying raw comb into clean blocks of wax. The specific equipment used often depends on the scale of the operation.

Step 1: Initial Separation

The first step is to separate the bulk of the honey from the wax. A common low-tech method is to place the wax cappings or crushed comb into a bucket.

The lighter wax will float to the top, while the heavier honey settles at the bottom. This gravity-based separation can recover a significant portion of the wax before melting even begins.

Step 2: Melting the Wax

To remove the remaining impurities, the wax must be melted. There are two primary tools for this job.

Solar melters are often used by hobbyists. They are essentially insulated boxes with a glass top that use the sun's heat to gently melt the wax, which then drips through a filter into a collection pan.

Electric melters are favored by commercial beekeepers who process large volumes. These devices provide consistent, controlled heat to render wax far more quickly than solar methods.

Step 3: Filtering for Purity

Melting alone is not enough. The liquid wax must be strained to remove physical impurities like propolis, larval molts, and other hive debris.

This is typically done by pouring the hot, liquid wax through filters like cheesecloth or fine mesh screens. For very pure wax, this process may be repeated multiple times.

Understanding the Trade-offs

Harvesting beeswax involves balancing effort, equipment, and the desired quality of the final product.

Quality vs. Source

Wax from cappings is clean, bright yellow, and requires minimal filtering. It's ideal for cosmetics or candles where purity and color are important.

Wax from old brood comb yields a larger quantity but is much darker and requires more intensive filtering. This wax is perfectly suitable for applications like wood polish or general waterproofing.

Effort vs. Reward

Rendering beeswax is a sticky, time-consuming process. However, it ensures that none of the bees' incredible work goes to waste.

The reward is a beautiful, natural, and valuable product with a vast range of uses, making the effort worthwhile for most beekeepers.

How to Apply This to Your Goal

Your approach to beeswax depends entirely on your role and your objective.

- If your primary focus is hobby beekeeping: Start with a simple solar melter or a dedicated double-boiler to process the high-quality wax from your cappings.

- If your primary focus is a commercial operation: Invest in an efficient electric melter to handle large volumes of both cappings and old comb quickly.

- If your primary focus is purchasing beeswax for a project: Pay attention to the color—a light, creamy yellow indicates purer wax from cappings, while a darker brown suggests it came from older brood comb.

By carefully melting and filtering what would otherwise be a waste product, beekeepers transform the diligent labor of their hives into a valuable and sustainable resource.

Summary Table:

| Source of Beeswax | Wax Quality | Primary Use |

|---|---|---|

| Wax Cappings (honey cell lids) | High - Light color, pure | Cosmetics, high-quality candles |

| Old/Unused Comb (brood comb) | Lower - Darker, more impurities | Wood polish, waterproofing |

Ready to scale your beeswax production or start your operation?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the durable, high-volume equipment needed for efficient wax rendering. Whether you need robust electric melters for large-scale processing or reliable filters for superior purity, we provide the wholesale solutions to maximize your yield and profitability.

Contact our experts today to discuss the best equipment for your apiary's needs.

Visual Guide

Related Products

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- HONESTBEE 6 Frame Three Use Electric Honey Extractor for Beekeeping

People Also Ask

- What role do precision wax melting units and molds play? Professional Beeswax Processing & Crafting Guide

- What makes polyurethane foam environmentally friendly? The Surprising Benefits of a Durable, Inert Material

- What happens to beeswax if it is heated beyond 170F? Prevent Irreversible Quality Loss and Darkening

- What are the primary products of honey bee farming besides honey? Discover the Hive's Hidden Treasures

- How does a steam wax melter work? A Fast, Efficient Method for High-Quality Wax