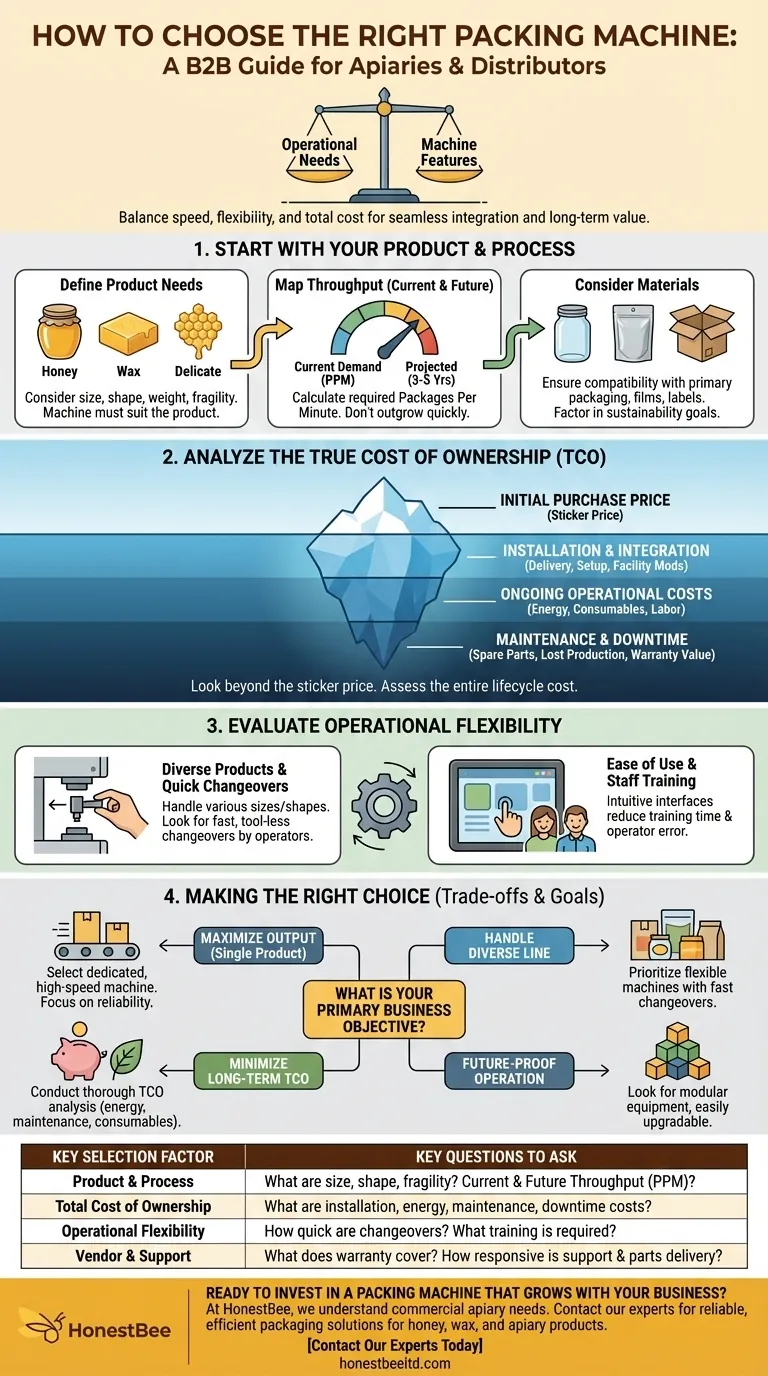

To choose the right packing machine, you must evaluate it against your specific operational needs. The decision hinges on a balance of key factors including the machine's speed, its flexibility to handle different products, the total cost of ownership, and the level of support and training provided by the vendor.

The best packing machine is not the fastest or the cheapest. It is the one that integrates seamlessly into your production line, aligns with your business goals, and delivers the lowest total cost of ownership over its lifespan.

Start with Your Product and Process

Before you can evaluate any machine, you must have a deep understanding of what you need to package and at what scale. The machine serves the product, not the other way around.

Define Your Product's Needs

Your product's physical characteristics are the primary constraint. Consider its size, shape, weight, and fragility. A machine designed for durable goods will damage delicate items, while a system for small pouches cannot handle large boxes.

Map Your Current and Future Throughput

Throughput, or speed, is a critical factor. Calculate your required packages per minute (PPM) or per hour for your current demand. Crucially, you must also project your needs for the next 3-5 years to avoid purchasing a machine that you will quickly outgrow.

Consider Your Packaging Materials

The machine must be compatible with your chosen packaging materials. This includes not only the primary packaging but also any films, adhesives, or labels. This is also where sustainability goals come into play, as "eco-friendly" materials can sometimes require specialized or slower equipment.

Analyze the True Cost of Ownership

The sticker price of a machine is only the beginning of your investment. A comprehensive financial analysis looks at the entire lifecycle cost.

The Initial Purchase Price

This is the most obvious cost. Obtain quotes from multiple vendors to establish a baseline, but do not let this be your only deciding factor. A cheaper machine can often have higher long-term costs.

Installation and Integration Costs

Consider the costs of delivery, installation, and integration with your existing production line. Does the machine require special electrical work, compressed air, or modifications to your facility layout? These expenses add up quickly.

Ongoing Operational Costs

This includes the cost of energy, compressed air, consumables (like film or glue), and labor. An efficient machine may have a higher purchase price but can save you significant money over several years of operation.

Maintenance and Downtime Costs

Every machine requires maintenance. Ask about the cost of common spare parts and the recommended maintenance schedule. Factor in the cost of potential downtime, as a single hour of lost production can be more expensive than a premium component. A strong warranty is an indicator of the manufacturer's confidence in their equipment's reliability.

Evaluate Operational Flexibility

In a dynamic market, the ability to adapt is a competitive advantage. A machine's flexibility determines how easily you can respond to new opportunities or product variations.

Handling Different Products and Formats

If you have a diverse product line or plan to introduce new SKUs, you need a machine that can handle various sizes and shapes. Ask about the process for changeovers between different product runs.

Ease of Changeover

A "flexible" machine is useless if it takes hours and a specialized technician to switch from one product to another. Look for systems that offer quick, tool-less changeovers that can be performed by your line operators. This directly impacts your operational efficiency and uptime.

The Need for Staff Training

A complex machine requires well-trained operators to run it efficiently and safely. Evaluate the quality of the training provided by the vendor. Intuitive, easy-to-use interfaces can reduce training time and minimize operator error.

Understanding the Trade-offs

Choosing a packing machine involves balancing competing priorities. Being aware of common pitfalls will help you make a more informed decision.

Over-investing in Speed You Don't Need

Paying a premium for a machine that runs at 200 PPM is a waste of capital if the rest of your production line can only supply it with 80 PPM. Your packaging machine should be paced to match your overall line speed.

Underestimating the Importance of Support

When a machine goes down, your entire operation can stop. A vendor with a reputation for poor technical support and slow parts delivery is a significant business risk, regardless of how good the machine seems. The warranty period and service level agreements are critical.

Ignoring Integration Challenges

A new packing machine must "talk" to the equipment upstream (like fillers or conveyors) and downstream (like case packers or palletizers). Ensure the controls and communication protocols are compatible to avoid a costly and frustrating integration project.

Making the Right Choice for Your Goal

Your final decision should be guided by your primary business objective.

- If your primary focus is maximizing output on a single product: Select a dedicated, high-speed machine from a vendor with a proven track record for reliability and support.

- If your primary focus is handling a diverse and changing product line: Prioritize flexible machines with fast, tool-less changeovers, even if it means a lower maximum speed.

- If your primary focus is minimizing long-term operational costs: Conduct a thorough Total Cost of Ownership (TCO) analysis, focusing on energy use, maintenance, and consumable costs.

- If your primary focus is future-proofing your operation: Look for modular equipment that can be easily upgraded or expanded as your production demands increase.

A thorough analysis of your unique operational needs transforms this from a machine purchase into a strategic business investment.

Summary Table:

| Key Selection Factor | Key Questions to Ask |

|---|---|

| Product & Process | What are the product's size, shape, and fragility? What is your current and future throughput (PPM)? |

| Total Cost of Ownership | What are the installation, energy, maintenance, and downtime costs beyond the purchase price? |

| Operational Flexibility | How quickly can you changeover between products? What level of staff training is required? |

| Vendor & Support | What does the warranty cover? How responsive is the technical support and parts delivery? |

Ready to invest in a packing machine that grows with your business?

At HONESTBEE, we understand that commercial apiaries and equipment distributors need reliable, efficient packaging solutions. We supply wholesale-focused beekeeping equipment and supplies, and our expertise can help you select a machine that integrates seamlessly, minimizes your total cost of ownership, and maximizes your operational uptime.

Contact our experts today for a personalized consultation to find the perfect packing solution for your honey, wax, and other apiary products.

Visual Guide

Related Products

- Professional Durable Customizable Blister Packing Machine

- HONESTBEE Professional Benchtop Pneumatic Bottle Capping Machine Capper

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Automatic In-Line Flat Surface Labeling Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

People Also Ask

- What are the essential safety tips for operating a honey stick machine? Ensure Zero-Risk Production Efficiency

- What is the purpose of a packaging machine? Boost Efficiency & Cut Costs for Your Business

- What are the benefits of using packaging machines? Boost Efficiency, Cut Costs & Elevate Your Brand

- Why is the selection of professional packaging tools and materials critical in the honey supply chain? Protect Your Brand

- What is the importance of versatility and adaptability in a honey packaging machine? Future-Proof Your Production