The fundamental difference between manual and automatic honey extractors is the power source. Manual extractors rely on a hand-crank operated by the user, while automatic (electric) extractors use an electric motor to spin the frames. This single distinction dictates their cost, efficiency, and suitability for different scales of beekeeping.

The choice between a manual and an automatic honey extractor is not about which is "better," but which is the right tool for your specific operation. It's a strategic decision that balances your budget, the number of hives you manage, and the value of your time and labor.

The Core Mechanism: Hand Power vs. Motor Power

The goal of any extractor is the same: to use centrifugal force to sling honey from the frames without damaging the delicate wax comb. How that force is generated is the key differentiator.

Manual Extractor Operation

A manual extractor features a hand-crank that you turn to spin an internal basket holding the honey frames. The speed and duration of the spin are entirely controlled by your physical effort.

This direct control allows for a gentle start, but maintaining a consistent and effective speed requires significant labor.

Automatic Extractor Operation

An automatic, or electric, extractor uses an electric motor to do the work. You simply load the frames, close the lid, and set the speed and time on a control panel.

The motor provides consistent, hands-free operation, dramatically increasing speed and reducing physical strain.

How Scale Dictates Your Choice

The number of hives you manage is the most critical factor in determining which type of extractor you need.

For the Hobbyist (Fewer than 10 Hives)

For small-scale beekeepers, a manual extractor is often the most practical and economical choice. The lower volume of honey to be processed doesn't justify the higher cost of an automatic model.

The physical effort required is manageable when you're only processing a few batches of frames per season.

For the Commercial or Sideliner Beekeeper

Once you manage a larger number of hives, time and labor become significant costs. An automatic extractor becomes a necessary investment.

It can process a much larger volume of frames in a fraction of the time, boosting productivity and ensuring the operation remains profitable and physically sustainable.

Understanding the Trade-offs

Each type of extractor comes with its own set of advantages and disadvantages that go beyond the initial purchase price.

Cost vs. Long-Term Value

Manual extractors have a much lower upfront cost, making them accessible to beginners and hobbyists on a tight budget.

Automatic extractors are a significant investment, but for larger operations, they deliver long-term value by drastically reducing labor costs and increasing overall production capacity.

Time and Physical Effort

The primary drawback of a manual extractor is the immense physical effort and time required. Cranking can be strenuous, especially during large harvests.

Automatic extractors almost completely eliminate this manual labor, freeing you to perform other tasks like uncapping the next batch of frames.

Consistency and Honey Quality

With an automatic extractor, you can set a precise speed, leading to a more consistent and efficient extraction. This ensures maximum honey yield while minimizing stress on the combs.

While a skilled operator can achieve good results with a manual extractor, it's harder to maintain the perfect speed, which can sometimes lead to incomplete extraction or damaged frames.

Making the Right Choice for Your Goal

Ultimately, the best extractor is the one that aligns with your operational goals and resources.

- If your primary focus is keeping startup costs low for a few hives: A manual extractor is the most budget-friendly and practical solution.

- If your primary focus is maximizing efficiency for a growing operation: An automatic extractor is a necessary investment to save time and reduce labor.

- If your primary focus is minimizing physical strain regardless of hive count: An automatic extractor provides a level of convenience that manual cranking cannot match.

Choosing the right tool for the scale of your work ensures your honey harvest is a rewarding, rather than exhausting, experience.

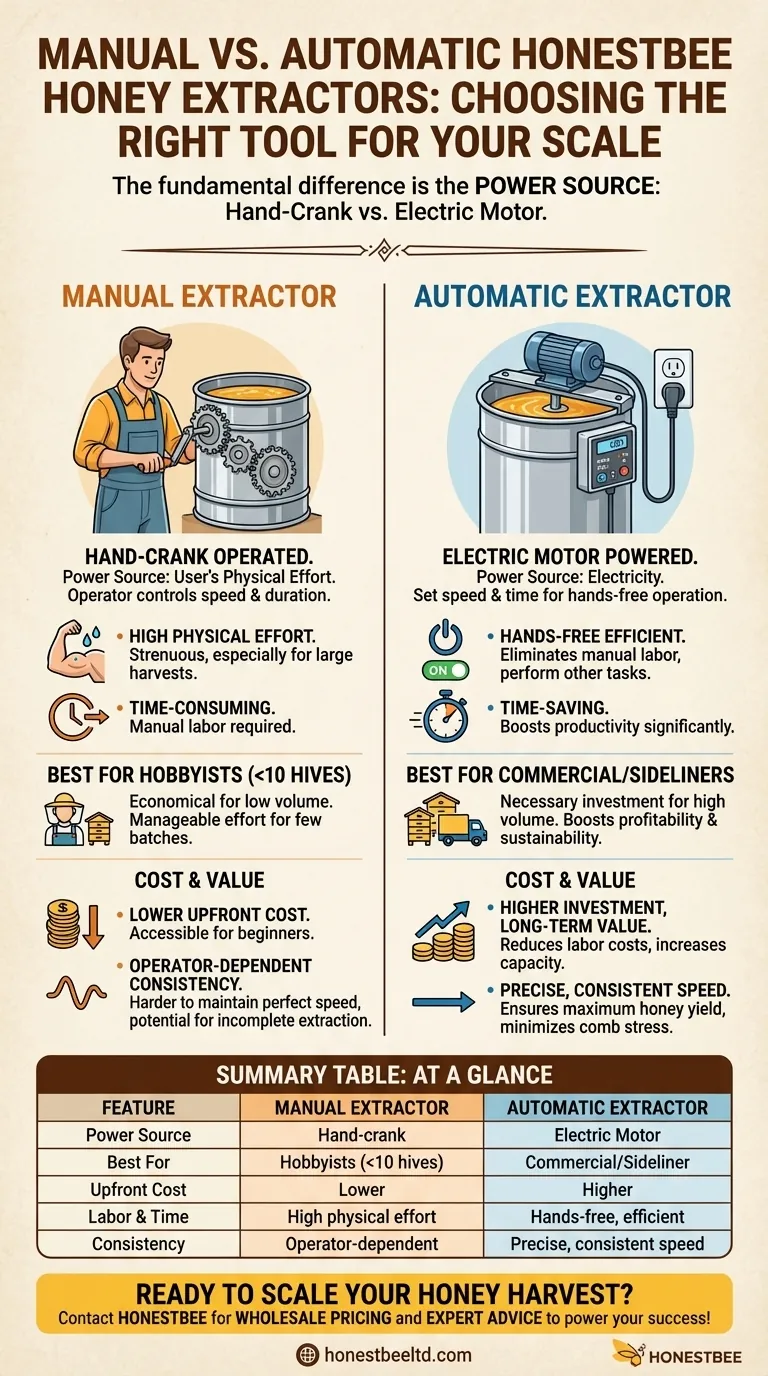

Summary Table:

| Feature | Manual Extractor | Automatic Extractor |

|---|---|---|

| Power Source | Hand-crank | Electric Motor |

| Best For | Hobbyists (<10 hives) | Commercial/Sideliner Beekeepers |

| Upfront Cost | Lower | Higher |

| Labor & Time | High physical effort | Hands-free, efficient |

| Consistency | Operator-dependent | Precise, consistent speed |

Ready to Scale Your Honey Harvest?

Choosing the right extractor is crucial for your operation's efficiency and profitability. Whether you're a commercial apiary or a beekeeping equipment distributor, HONESTBEE has the wholesale-focused solutions you need.

We supply durable, high-performance beekeeping equipment tailored for volume and reliability. Let us help you select the perfect extractor to maximize your yield and minimize labor.

Contact HONESTBEE today for wholesale pricing and expert advice to power your success!

Visual Guide

Related Products

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

- Stainless Steel 3 Frame Manual Honey Extractor Spinner for Bee Honey Extraction

People Also Ask

- How do you collect honey at home? A Beginner's Guide to Harvesting from Your Hive

- What is the most common method for cleaning a honey extractor? Protect Your Honey & Equipment

- What should be considered when harvesting honey from multiple hives? Scale Your Harvest Efficiently

- What size honey extractor do I need? Match Frame Capacity to Your Hives for Maximum Efficiency

- What is the pressing method for extracting honey? A Simple, Low-Cost Approach for Small-Scale Beekeepers