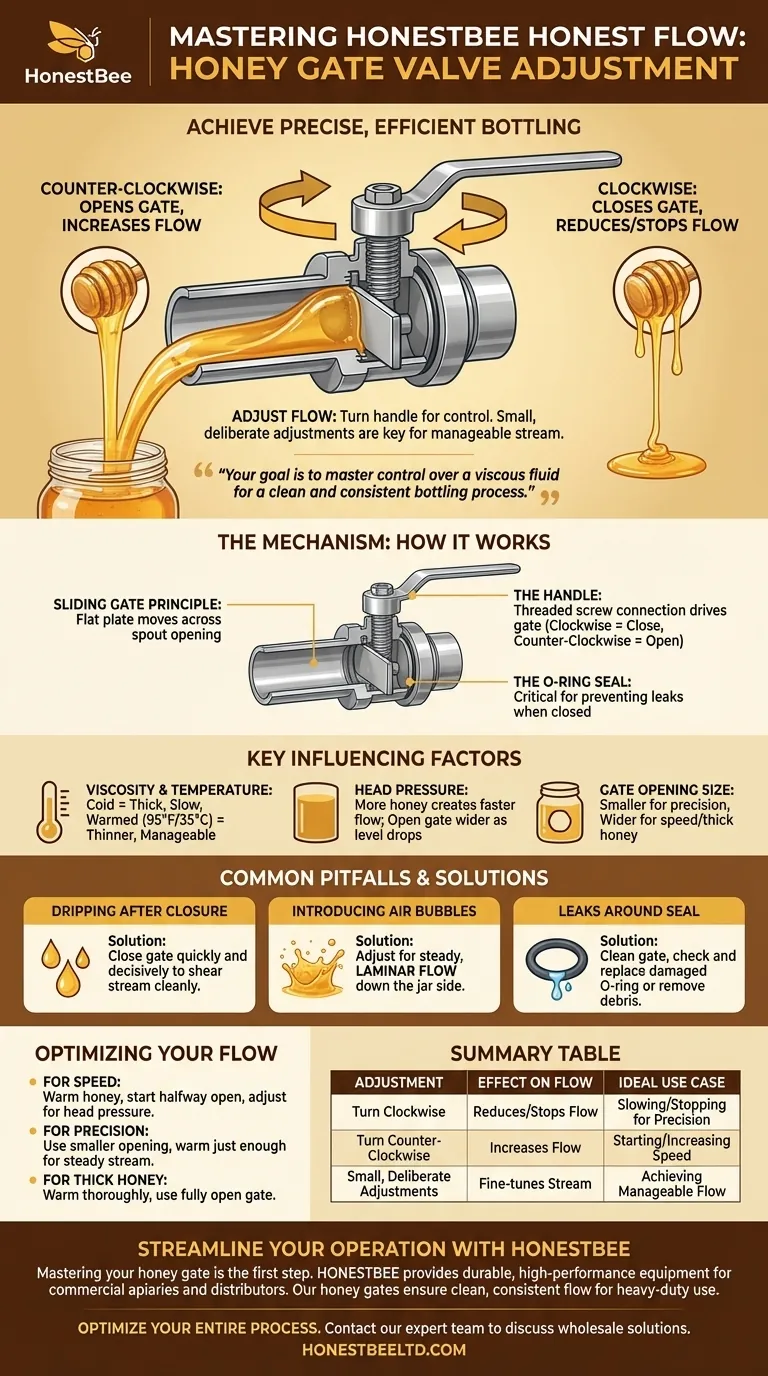

To adjust a honey gate valve, you control the flow by turning the handle. Turning the handle clockwise closes the gate and reduces or stops the flow of honey. Turning it counter-clockwise opens the gate, increasing the flow. The key is to make small, deliberate adjustments to achieve a stream that is both manageable and efficient for your bottling task.

Your goal is not just to open or close a valve, but to master control over a viscous fluid. True efficiency comes from understanding how factors like honey temperature and container fullness affect the flow, allowing you to maintain a clean and consistent bottling process from the first jar to the last.

The Mechanism: How a Honey Gate Works

Understanding the simple mechanics of your honey gate demystifies the process and gives you greater control. It is a straightforward tool designed for a specific purpose: regulating the flow of a thick liquid.

The Sliding Gate Principle

At its core, the valve uses a flat plate, or "gate," that slides within a sealed housing. When you operate the handle, this gate moves across the opening of the spout.

The Role of the Handle

The handle is connected to a threaded screw. Turning it clockwise drives the gate forward, gradually closing the opening. Turning it counter-clockwise retracts the gate, clearing the path for the honey to flow out.

The Importance of the O-ring

A silicone or rubber O-ring sits in a groove where the gate presses against the valve body. This seal is critical for preventing slow, sticky leaks when the gate is fully closed.

Key Factors Influencing Honey Flow

Simply turning the handle is only part of the story. The behavior of your honey is governed by physics, and understanding these principles is essential for a smooth operation.

Viscosity and Temperature

This is the single most important factor. Honey's viscosity (its thickness and resistance to flow) is highly dependent on its temperature.

Cold honey is extremely thick and will flow very slowly, even with the gate wide open. Gently warmed honey (to around 95°F or 35°C) becomes significantly thinner and more manageable.

Head Pressure

The amount of honey in your tank or bucket creates head pressure. A full tank exerts more pressure, causing the honey to flow much faster than when the tank is nearly empty.

You must be prepared to open the gate wider as the honey level drops to maintain a consistent flow rate.

Gate Opening Size

The degree to which you open the gate determines the final flow rate. A smaller opening is ideal for filling small jars where precision is key. A wider opening allows for a faster fill on larger containers or helps move very thick, viscous honey.

Common Pitfalls to Avoid

Even with a simple tool, certain issues can arise. Anticipating them will save you time and prevent a sticky mess.

Problem: Dripping After Closure

A common frustration is the persistent drip after you've closed the gate. This is often caused by closing the valve too slowly, which leaves a string of honey that eventually breaks and drips.

Solution: Close the gate with a quick, decisive motion. This shears the honey stream cleanly, minimizing drips. Keep a damp cloth or a small dish handy to catch any residual drops.

Problem: Introducing Air Bubbles

If the honey flows too quickly and splashes into the jar, it will introduce air bubbles that look unsightly and can contribute to faster crystallization.

Solution: Adjust the gate for a steady, laminar flow—a smooth, glass-like stream that doesn't churn or splash. Aim the stream down the side of the jar, not directly into the center.

Problem: Leaks Around the Seal

If your gate leaks even when fully tightened, the cause is almost always one of two things. The O-ring may be worn, damaged, or unseated, or a honey crystal may be lodged in the seal, preventing a tight closure.

Solution: Disassemble and clean the gate thoroughly, paying close attention to the O-ring and its channel. If the O-ring is cracked or stretched, it must be replaced.

Optimizing Your Flow for Your Goal

The right technique depends on what you are trying to achieve. Use these guidelines to tailor your approach.

- If your primary focus is speed and efficiency: Gently warm your honey and start with the gate about halfway open, adjusting as needed to manage the initial head pressure.

- If your primary focus is precision and cleanliness: Use a smaller gate opening for maximum control, and ensure your honey is just warm enough to flow in a steady, predictable stream.

- If you are bottling thick or crystallized honey: You must warm the honey thoroughly and will likely need the gate fully open to achieve any meaningful flow.

By balancing these factors, you transform bottling from a chore into a controlled and satisfying process.

Summary Table:

| Adjustment | Effect on Flow | Ideal Use Case |

|---|---|---|

| Turn Handle Clockwise | Reduces or stops flow | Slowing down for precision, stopping flow |

| Turn Handle Counter-Clockwise | Increases flow | Starting flow, increasing speed for larger containers |

| Small, Deliberate Adjustments | Fine-tunes stream | Achieving a manageable, consistent flow |

Streamline your commercial honey bottling operation with HONESTBEE.

Mastering your honey gate valve is just the first step toward a more efficient and profitable bottling line. As a leading wholesale supplier to commercial apiaries and beekeeping equipment distributors, HONESTBEE provides the durable, high-performance equipment you need.

We understand the challenges of large-scale honey processing. Our honey gates are designed for heavy-duty use, featuring robust seals and precise mechanisms to ensure a clean, consistent flow, batch after batch.

Let us help you optimize your entire process. Contact our expert team today to discuss your equipment needs and discover how our wholesale solutions can enhance your productivity and bottom line.

Visual Guide

Related Products

- Stainless Steel Honey Gate Valve Tap Tool for Honey Extractor

- Honey Gate Valve with Ergonomic Ball Handle Plastic Bee Honey Tap for Beekeeping Bottling and Honey Extractor Equipment

- Premium Diamond-Faceted Glass Honey Dispenser

- Honeycomb Style Drip Free Honey Dispenser

- Inverted Squeezable Honey Jar with No Drip Flip Top Cap for Easy Pouring

People Also Ask

- What is the proper procedure for cleaning and maintaining a honey gate? Prolong Your Equipment's Life

- What are the steps for cleaning and maintaining a honey gate? Ensure Honey Purity and Prevent Costly Leaks

- How should a honey gate be properly installed? Ensure a Leak-Proof Seal for Your Honey Extraction

- What are the design advantages of a knife-type honey gate valve? Stop Drips and Improve Extraction Efficiency

- Can a honey gate be reused? Maximize the Lifespan of Your Beekeeping Extraction Equipment

- Can a honey gate be reused, and how should it be stored? Ensure Longevity for Your Honey Harvests

- What is a honey gate and what is its primary function? Control Your Honey Flow Efficiently

- How do you properly install a honey gate? Prevent Leaks and Protect Your Honey Harvest