At its core, cold pressing honey is a simple, traditional method that uses mechanical force—not heat—to separate honey from its wax comb. The honeycomb is crushed or pressed, forcing the raw honey through a strainer, which leaves the solid wax behind. This minimal processing ensures the final product is as close as possible to its natural state within the hive.

The essential difference between cold-pressed honey and conventional honey is the deliberate avoidance of heat. This single choice preserves the delicate enzymes, pollen, and volatile aromatics that define the honey's unique character but are often damaged or removed by commercial processing.

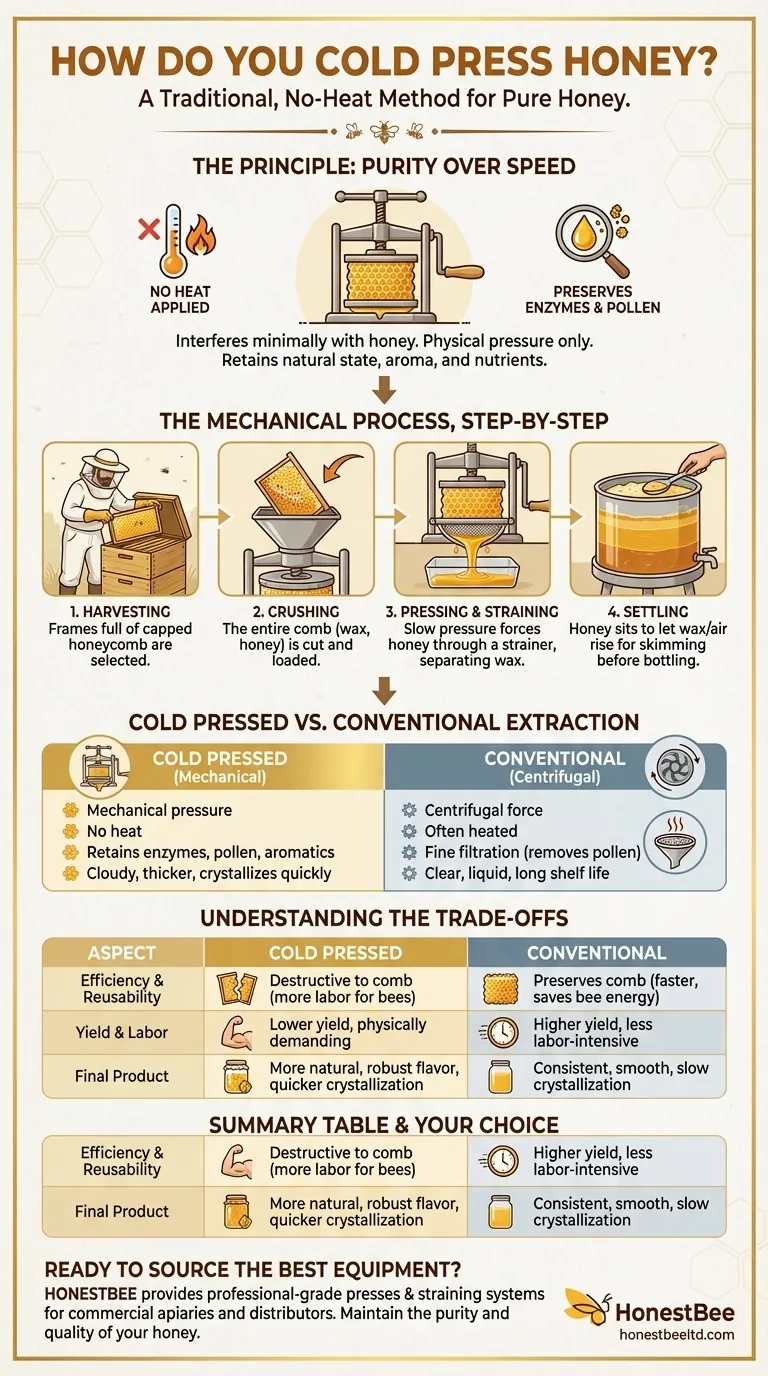

The Principle of Cold Pressing: Purity Over Speed

The philosophy behind cold pressing is to interfere with the honey as little as possible. It prioritizes retaining the natural components of the honey over the speed and efficiency of extraction.

What "Cold Pressed" Truly Means

The term "cold" signifies the absence of any applied heat during the extraction process. The entire separation is achieved through physical pressure.

This stands in stark contrast to many large-scale operations which may use "preheating" to lower the honey's viscosity, making it flow faster through filters and bottling equipment.

The Mechanical Process, Step-by-Step

While setups can vary from small-scale hobbyist presses to larger commercial equipment, the core steps remain the same.

- Harvesting: Frames full of capped honeycomb are carefully selected and removed from the hive.

- Crushing: The entire comb—wax, honey, and all—is cut from the frames and placed into a press. This breaks open the wax cells, releasing the honey.

- Pressing & Straining: A press applies slow, steady pressure to the crushed comb. The liquid honey is forced out and passes through a mesh or screen, which separates it from the solid beeswax.

- Settling: The extracted honey is often left to sit in a tank. This allows finer wax particles and air bubbles to naturally rise to the surface, where they can be skimmed off before bottling.

Cold Pressed vs. Conventional Extraction

Understanding cold pressing is easier when you compare it to the more common industrial method: centrifugal extraction.

The Conventional Method: Speed and Heat

Most commercial honey is extracted using a machine called a centrifugal extractor. Beekeepers first slice the wax caps off the comb (a step called "uncapping") and then place the frames inside the extractor.

The machine spins the frames at high speed, using centrifugal force to sling the honey out of the comb without destroying it. The honey is then often gently heated and finely filtered to create a clear, liquid product with a long shelf life.

The Impact of Heat and Filtration

Even low levels of heat can degrade the natural enzymes in honey, such as diastase and invertase, which are valued for their potential health benefits. Heat can also drive off delicate aromatic compounds, resulting in a less complex flavor profile.

Furthermore, the fine filtration common in conventional processing can remove most of the naturally occurring pollen. Cold-pressed honey is typically only strained, not filtered, meaning it retains these microscopic traces of pollen and propolis.

Understanding the Trade-offs

If cold pressing results in a more natural product, it's fair to ask why all honey isn't extracted this way. The answer lies in practical trade-offs between quality and efficiency.

Efficiency and Reusability

Centrifugal extraction is significantly faster and less labor-intensive than pressing. Crucially, it preserves the wax comb. Bees expend a tremendous amount of energy to build a comb, and being able to return an empty comb to the hive for refilling saves them weeks of work.

Yield and Labor

Cold pressing is a destructive process for the comb. It is also more physically demanding and can result in a lower yield, as some honey inevitably remains trapped within the pressed wax block.

The Final Product

Cold-pressed honey is often thicker, cloudier, and more flavorful than its conventional counterpart, as noted by producers. It also tends to crystallize more quickly because the retained pollen and wax particles provide nucleation points for crystals to form. This is a natural characteristic, not a flaw.

Making the Right Choice for Your Goal

Ultimately, the "best" honey depends entirely on your priorities.

- If your primary focus is preserving the most natural state: Seek out honey labeled "cold pressed" or "raw and unfiltered," as this guarantees minimal processing and retains the full spectrum of enzymes, pollen, and flavor.

- If your primary focus is a clear, liquid honey for tea or baking: A standard, heat-treated commercial honey is perfectly suitable, offering consistency and a long shelf life without crystallization.

- If you are a beekeeper: You must weigh the premium, artisanal quality of cold-pressed honey against the immense efficiency and hive-health benefits of preserving your wax combs through centrifugal extraction.

Understanding the journey from comb to bottle empowers you to choose honey based not just on taste, but on the principles behind its production.

Summary Table:

| Aspect | Cold Pressed Honey | Conventional Honey |

|---|---|---|

| Processing Method | Mechanical pressure, no heat | Centrifugal force, often with heat |

| Key Characteristic | Retains enzymes, pollen, aromatics | Clear, liquid, long shelf life |

| Final Product | Cloudy, thicker, quick crystallization | Smooth, consistent, slow crystallization |

| Best For | Raw honey enthusiasts, natural product seekers | General use, baking, clear liquid preference |

Ready to Source the Best Equipment for Your Honey Production?

Whether you're a commercial apiary scaling up your cold press operations or a distributor looking for reliable wholesale supplies, HONESTBEE provides the professional-grade beekeeping equipment you need. From durable presses to straining systems, we help you maintain the purity and quality of your honey.

Contact HONESTBEE today to discuss your wholesale equipment needs and ensure your honey retains its natural goodness.

Visual Guide

Related Products

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- How does the honey pressing method offer flexibility in hive management regarding comb structure? Simplify Your Harvest

- What is the 'crush & strain' method for harvesting honey? The Ultimate Low-Cost Guide to Manual Extraction

- What is the advantage of cycling out wax by pressing honeycomb? Improve Apiary Health and Wax Quality

- What is the advantage of pressing and bottling honey one comb at a time? Unlock Unique Artisan Flavor Profiles

- How is a fruit or honey press used to extract honey from comb? Master Cold-Pressed Honey for Maximum Purity

- How does the Honey-Wax Separating Screw Press process cappings? Maximize Honey Yield and Efficiency

- What are the multipurpose functionalities of a honey press? Versatile Harvesting for Beekeepers & Homesteaders

- What makes pressing honey a comparatively clean and tidy extraction method? Discover the Mess-Free Workflow