To prepare honey for bottling, you must gently warm it to a target temperature between 110°F and 118°F (43°C to 48°C). This process is designed to liquefy crystallized honey, making it easy to strain and pour without "cooking" it or degrading its natural qualities. The key is to use slow, indirect heat, never applying a heat source directly to the honey container.

The fundamental goal is not just to liquefy the honey, but to do so while preserving its delicate enzymes, aroma, and flavor. Overheating is the single biggest mistake in honey preparation, and it is entirely avoidable with the right technique.

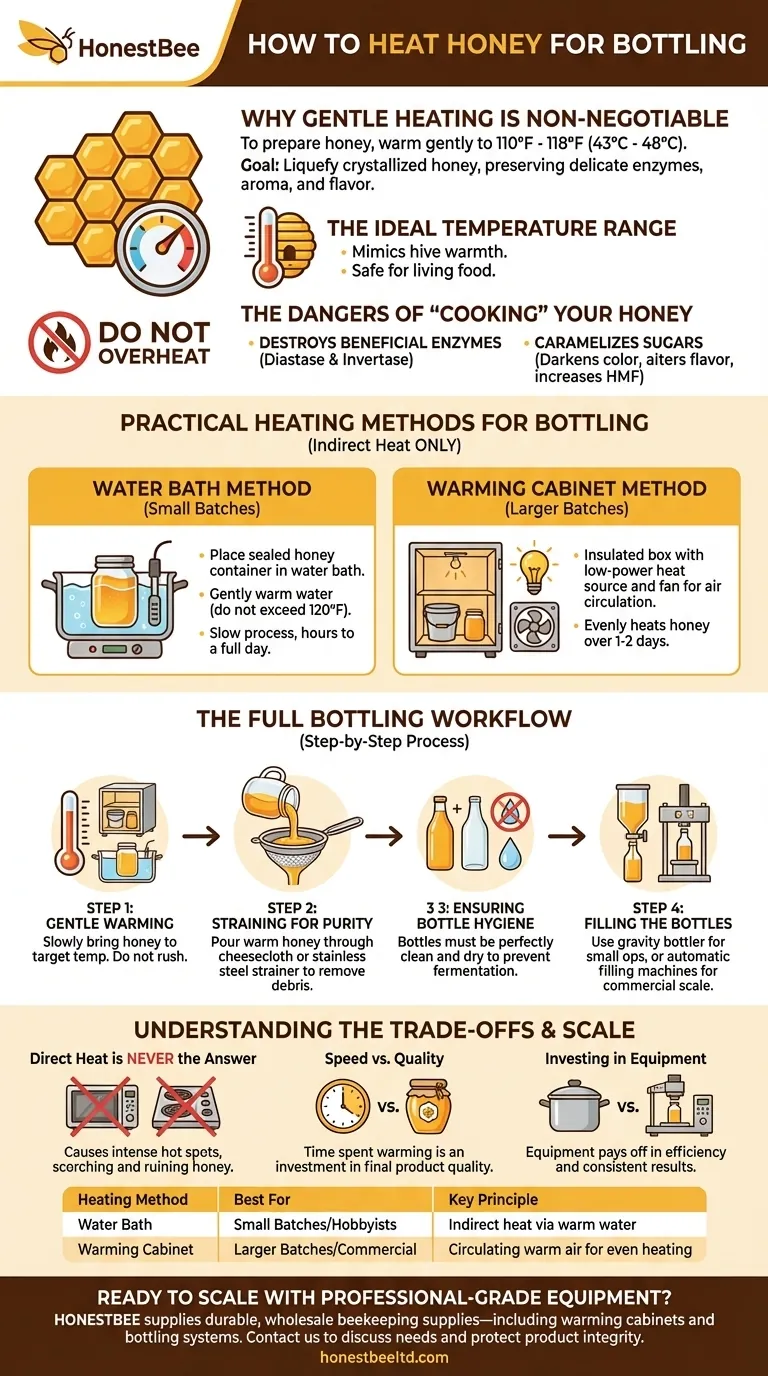

Why Gentle Heating is Non-Negotiable

Raw honey is a living food, full of beneficial enzymes and volatile compounds that create its unique flavor and aroma. Applying excessive heat permanently damages these properties.

The Ideal Temperature Range

The target of 110°F to 118°F (43°C to 48°C) is chosen for a specific reason. It safely mimics the temperature inside a bustling beehive on a hot summer day, providing enough warmth to reliquefy crystals without harming the honey.

The Dangers of "Cooking" Your Honey

When honey is overheated, two primary things happen. First, beneficial enzymes like diastase and invertase are destroyed. Second, its sugars begin to caramelize, which darkens the color, alters the flavor, and increases the level of a compound called HMF (hydroxymethylfurfural), an indicator of heat damage.

Practical Heating Methods for Bottling

The best method depends on your batch size. In all cases, the principle is to heat the air or water around the honey container, not the container itself.

The Water Bath Method (For Small Batches)

This is the simplest and most common method for hobbyists. Place your sealed bucket or jar of honey into a larger pot of water. Use a submersible heater or your stovetop on its lowest setting to gently warm the water, using a thermometer to ensure the water does not exceed 120°F.

This process is slow and can take several hours to a full day for a 5-gallon bucket. Patience is essential.

The Warming Cabinet Method (For Larger Batches)

For those processing larger volumes, a warming cabinet is more efficient. This is an insulated box containing a low-power heat source (like a 100-watt light bulb or a small heater) and a fan for air circulation.

The circulating warm air gently and evenly heats the honey buckets over 1-2 days. You can build a simple version yourself or purchase a professionally made unit.

The Full Bottling Workflow

Heating is just one step. To ensure a high-quality final product, you must follow a clear process from start to finish.

Step 1: Gentle Warming

Using one of the methods described above, slowly bring your honey to the target temperature. Do not rush this step.

Step 2: Straining for Purity

Once liquid, the honey must be strained. Pour the warm honey through a cheesecloth or a specialized stainless steel honey strainer. This removes any remaining wax cappings, bee parts, or other debris that may have been collected during extraction.

Step 3: Ensuring Bottle Hygiene

Your honey bottles must be perfectly clean and completely dry. Any moisture inside the bottle can increase the honey's overall water content, creating a risk of fermentation and spoilage down the line.

Step 4: Filling the Bottles

For small operations, a gravity bottler is effective. This is essentially a tank with a valve at the bottom that allows for controlled, clean filling by using gravity. For commercial scale, automatic filling machines provide high-speed, consistent bottling for thousands of units.

Understanding the Trade-offs

Choosing your method involves balancing speed, cost, and quality control.

Direct Heat is Never the Answer

Never use a microwave or place a container of honey directly on a stovetop. These methods create intense hot spots that will scorch and ruin the honey instantly, even if other parts of the container remain solid.

Speed vs. Quality

While you may be tempted to increase the temperature to speed up the liquefaction process, this is a critical mistake. The time spent gently warming honey is an investment in preserving the quality and value of your final product. There are no safe shortcuts.

Investing in Equipment

A simple water bath costs almost nothing, but a dedicated warming cabinet and gravity bottler can cost several hundred dollars. This investment pays for itself in time savings and, more importantly, in consistent, high-quality results as you scale your operation.

Making the Right Choice for Your Goal

Your bottling process should match your operational scale and commitment to quality.

- If your primary focus is bottling a few jars for friends and family: A simple water bath on a low-temperature setting is a perfect, low-cost solution.

- If your primary focus is a small-scale business or serious hobby: A dedicated warming cabinet and a gravity bottler will provide the consistency and efficiency you need.

- If your primary focus is a commercial operation: You must invest in integrated, temperature-controlled tanks and automated filling systems to ensure uniform quality at scale.

Ultimately, proper honey handling is a testament to your respect for the product and the bees that created it.

Summary Table:

| Heating Method | Best For | Key Principle |

|---|---|---|

| Water Bath | Small Batches/Hobbyists | Indirect heat via warm water |

| Warming Cabinet | Larger Batches/Commercial | Circulating warm air for even heating |

Ready to scale your honey bottling with professional-grade equipment?

HONESTBEE supplies durable, wholesale-focused beekeeping supplies and equipment—including warming cabinets and bottling systems—to commercial apiaries and distributors. We help you maintain the highest quality standards while improving efficiency.

Contact us today to discuss your specific needs and get a quote on reliable equipment that protects your product's integrity.

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

- Silicone Rubber Honey Drum Heating Belt

- 10L Stainless Steel Electric Honey Press Machine

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

People Also Ask

- Why is the use of precision temperature-controlled heating equipment necessary? Protect Your Bees from HMF Toxicity

- What are the benefits of precise temperature control in honey heating tanks? Preserve Quality and Efficiency

- What is the primary function of a honey heating tank? Master Your Honey Processing with Precision Control

- How do climate-controlled storage systems contribute to the preservation of honey shelf life? Expert Storage Guide

- Why is the heating process necessary during the honey bottling stage? Master Stabilization for Quality Results

- Why is the 150°C high-temperature paraffin dipping process recommended? Master Beehive Disinfection and Preservation

- What are the technical requirements for honey liquefaction? Ensure Quality with Precise Temperature Control

- Why is the heating unit position critical in beekeeping thermal equipment? Ensure Uniform Pest Control & Colony Safety