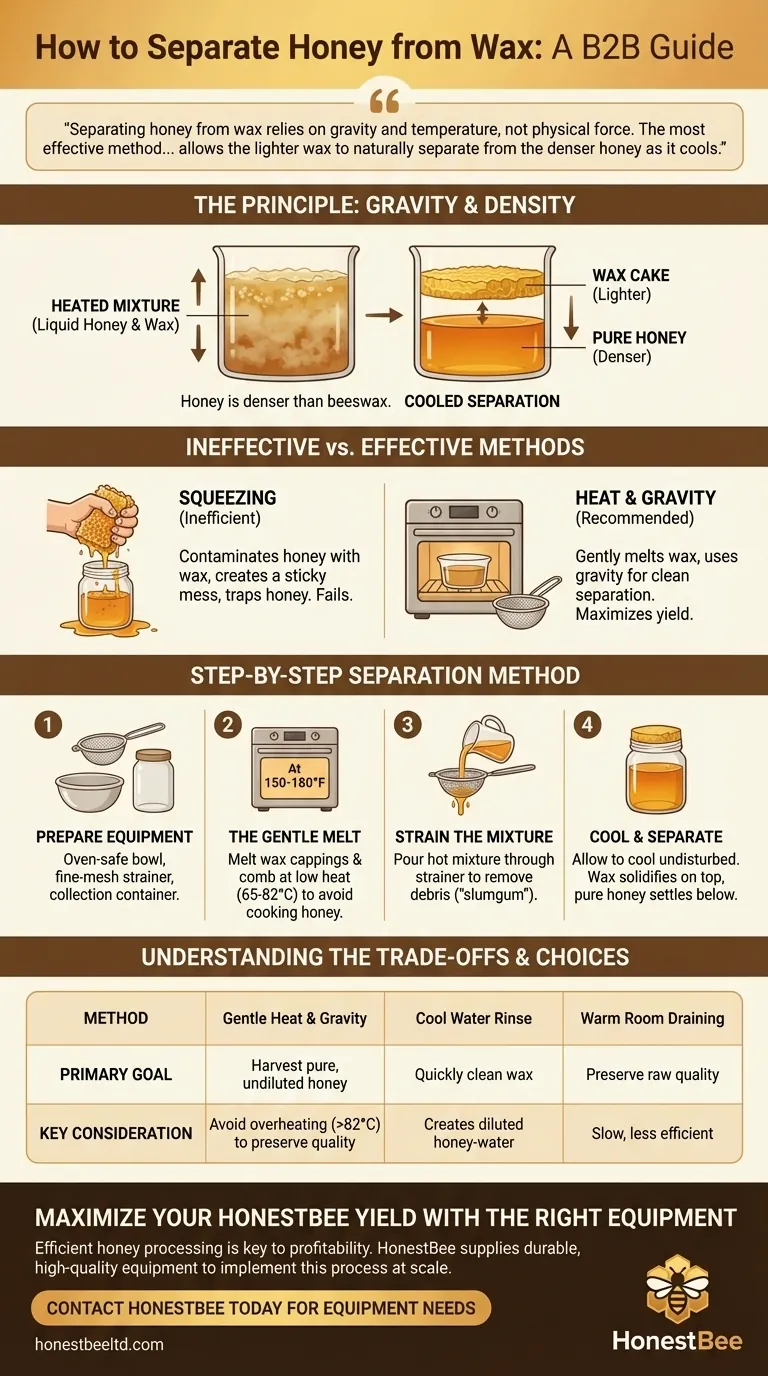

Separating honey from wax is a process that relies on gravity and temperature, not physical force. The most effective method involves gently melting the honeycomb or cappings, allowing the lighter wax to naturally separate from the denser honey as it cools. This ensures you recover the maximum amount of pure honey without damaging its quality.

The core principle is simple: when gently heated, both honey and wax will liquefy. Because wax is less dense than honey, it will float to the surface and form a solid, easily removable cake upon cooling, leaving pure honey below.

The Principle of Separation: Gravity and Density

Why Squeezing Is Ineffective

Attempting to squeeze honey from wax comb by hand or with a press is inefficient. This method contaminates the honey with wax particles, creates a sticky mess, and leaves a significant amount of honey trapped in the wax.

How Heat and Density Work Together

The magic of this process lies in the different physical properties of honey and beeswax. Honey is significantly denser than beeswax.

When you apply gentle heat, both substances turn to liquid. As the mixture rests and cools, gravity takes over. The less-dense liquid wax naturally rises to the top, while the heavier liquid honey settles at the bottom.

The Step-by-Step Separation Method

This process works best for separating honey from the wax cappings and broken bits of comb left over after honey extraction.

Step 1: Prepare Your Equipment

You will need a large, oven-safe bowl or pot, a fine-mesh strainer or several layers of cheesecloth, and a second container to catch the rendered honey.

Place the strainer or cheesecloth over your collection container.

Step 2: The Gentle Melt

Place your wax cappings and broken comb into the oven-safe bowl. Heat them using a very low temperature.

An oven on its lowest setting (around 150-180°F or 65-82°C) or a solar oven on a warm day is ideal. The goal is to melt the wax without "cooking" the honey.

Step 3: Strain the Mixture

Once the honey and wax are fully liquefied, carefully pour the hot mixture through your cheesecloth or strainer into the collection container. The cloth will catch any debris, known as "slumgum."

Step 4: The Cooling and Separation Phase

Allow the container of strained liquid to sit undisturbed at room temperature for several hours or overnight.

As it cools, you will see a clear division form. The wax will solidify into a hard, golden disk on the surface, while the clean, liquid honey will remain below. Once the wax is completely hard, you can lift it off in one piece.

Understanding the Trade-offs

The Risk of Overheating Honey

The most critical factor is temperature. Overheating honey (above 180°F or 82°C) will destroy its beneficial enzymes, darken its color, and alter its delicate flavor. Always use the lowest possible heat setting.

An Alternative: Rinsing with Water

Another method mentioned is rinsing the wax cappings with cool water to remove residual honey.

This is a fast and simple way to clean the wax, but it does not yield pure honey. Instead, you create a diluted honey-water solution, which is useful for starting mead or for certain baking recipes but is not a substitute for liquid honey.

Making the Right Choice for Your Goal

- If your primary focus is harvesting pure, undiluted honey: The gentle heat and gravity separation method is the definitive technique.

- If your primary focus is quickly cleaning wax with no special equipment: Rinsing with cool water is a viable option, but the resulting honey will be diluted.

- If you want to preserve the "raw" quality of the honey completely: You can place crushed comb in a strainer over a bucket in a very warm room (80-90°F) and let it drain for several days, though this is less efficient.

By using the right technique for your goal, you can confidently process your harvest and enjoy both pure honey and clean beeswax.

Summary Table:

| Method | Primary Goal | Key Consideration |

|---|---|---|

| Gentle Heat & Gravity | Harvest pure, undiluted honey | Avoid overheating (>82°C/180°F) to preserve honey quality |

| Cool Water Rinse | Quickly clean wax for rendering | Creates diluted honey-water, not pure honey |

| Warm Room Draining | Preserve raw honey quality | Slow process, less efficient for large batches |

Maximize Your Honey Yield with the Right Equipment

As a commercial apiary or beekeeping equipment distributor, efficient honey processing is key to your profitability. The gentle heat and gravity method described is the industry standard for preserving honey quality and maximizing recovery from cappings.

HONESTBEE supplies the durable, high-quality equipment you need to implement this process effectively and at scale. From fine-mesh strainers to temperature-controlled melters, our wholesale-focused operations ensure you get reliable gear that stands up to commercial use.

Ready to improve your honey recovery and wax rendering process? Contact HONESTBEE today to discuss your equipment needs and how we can support your operation's success.

Visual Guide

Related Products

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Stainless Steel Honey Press Wax Press with Tank

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

People Also Ask

- How is a bucket honey press operated? A Master Guide to Efficient Manual Honey and Wax Extraction

- How do honey presses benefit large-scale beekeeping operations? Maximize Commercial Throughput and Wax Yield

- What are the multipurpose functionalities of a honey press? Versatile Harvesting for Beekeepers & Homesteaders

- What is the advantage of the long handle on the honey press? Unlock Effortless Extraction with Minimal Force

- How do you separate honey from wax cappings? Choose the Best Method for Your Harvest

- What are the technical advantages of using the pressing method instead of centrifugation for honey harvesting?

- What role does a high-pressure hydraulic press play in processing merva? Boost Your Wax Recovery Yield Today

- Can the Honey Press be used for purposes other than honey extraction? Unlock Its Versatility for Juicing & Herbal Projects