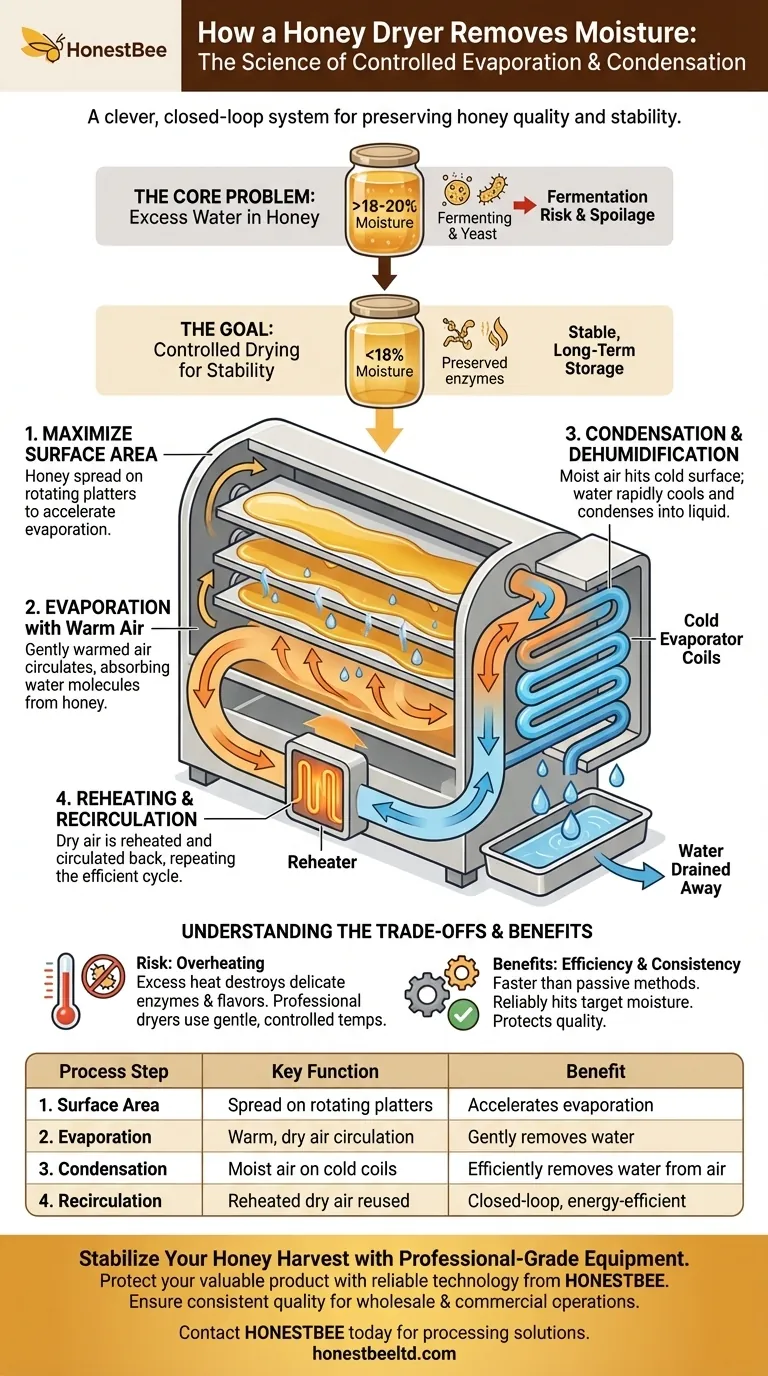

At its core, a honey dryer removes moisture using a clever, closed-loop system. It works by passing warm, dry air over the honey to absorb water, then channeling that moist air over a cold surface to condense the water out. This newly dried air is then reheated and circulated back over the honey to repeat the process until the desired moisture level is reached.

The critical insight is that a honey dryer doesn't just "blow hot air" on honey. It operates on a continuous cycle of evaporation and condensation, efficiently pulling water from the honey and then wringing that water out of the air in a controlled, self-contained loop.

The Core Problem: Excess Water in Honey

Before diving into the mechanics, it's crucial to understand why honey drying is necessary. The water content of honey is the single most important factor for its long-term stability.

Why Moisture Content Matters

Raw honey with a moisture content above 18-20% is at high risk of fermenting. Yeasts naturally present in honey can become active in this high-water environment, spoiling the batch and rendering it unsellable.

The Goal of Controlled Drying

The objective is to gently reduce the water content to a safe level (typically below 18%) for stable, long-term storage. This must be done without damaging the delicate enzymes, aromas, and beneficial properties that make honey valuable.

Deconstructing the Drying Process

A honey dryer accomplishes this goal through a precise, multi-step process based on the principle of condensation.

Step 1: Maximizing Surface Area

To accelerate evaporation, the honey is spread into a thin film. This is often accomplished using a system of slowly rotating platters or discs that continuously pick up a layer of honey and expose it to the circulating air.

Step 2: Evaporation with Warm Air

The system circulates gently warmed air through the chamber. This warm air passes over the thin film of honey on the platters, which encourages the water molecules to evaporate from the honey and become bound to the air.

Step 3: Condensation and Dehumidification

This is the key to the entire system. The now-moist air is pulled away from the honey and passed over a very cold surface, typically the evaporator coils of a heat pump. As the warm, moist air hits the cold coils, it rapidly cools, forcing the captured water to condense into liquid, which is then drained away.

Step 4: Reheating and Recirculation

After passing over the cold coils, the air is now devoid of its moisture. This dry air is then reheated and sent back into the chamber to pass over the honey again, picking up more water. This closed loop is highly efficient, continuously removing moisture without introducing outside air.

Understanding the Trade-offs

While effective, this technology involves specific considerations that are important for any honey processor to understand.

The Risk of Overheating

Heat is the enemy of high-quality honey. While a dryer uses warm air, excessive temperatures can destroy beneficial enzymes and delicate flavors. A professional condensation dryer is designed to work at gentle, controlled temperatures to preserve the honey's integrity.

Efficiency and Batch Size

The process is very effective but not instantaneous. A typical machine might reduce the moisture content of 72 kg of honey by 2-3% in about three hours. This is a significant improvement over passive methods but must be factored into production timelines.

Equipment vs. Passive Methods

A dedicated honey dryer is a significant investment compared to simply using a dehumidifier in a small, sealed room. However, it offers far greater speed, control, and consistency, making it a professional-grade tool for ensuring product quality.

Making the Right Choice for Your Goal

Understanding this process helps you decide if it aligns with your operational needs.

- If your primary focus is preserving honey quality: A condensation dryer provides the gentle, low-temperature control needed to protect delicate enzymes and flavors.

- If your primary focus is processing efficiency: The combination of increased surface area and a closed-loop drying system dramatically speeds up moisture removal compared to passive methods.

- If your primary focus is product consistency: This technology allows you to reliably hit a target moisture content, ensuring every batch meets the highest standards for long-term stability and sale.

Ultimately, a honey dryer is a specialized tool engineered to solve a critical problem: stabilizing honey while protecting its natural quality.

Summary Table:

| Process Step | Key Function | Benefit |

|---|---|---|

| 1. Surface Area Maximization | Honey spread on rotating platters | Accelerates evaporation rate |

| 2. Evaporation | Warm, dry air circulates over honey | Gently encourages water to leave honey |

| 3. Condensation | Moist air hits cold coils; water condenses | Removes water from the air efficiently |

| 4. Recirculation | Dry air is reheated and reused | Creates a closed-loop, energy-efficient system |

Stabilize Your Honey Harvest with Professional-Grade Equipment

As a commercial beekeeper or distributor, consistent honey quality is non-negotiable. Protect your valuable product from fermentation and preserve its delicate enzymes and flavors with reliable honey drying technology from HONESTBEE.

We supply durable, efficient beekeeping supplies and equipment tailored for wholesale and commercial operations. Let us help you ensure every batch meets the highest standards for moisture content and long-term stability.

Contact HONESTBEE today to discuss the right honey processing solutions for your apiary.

Visual Guide

Related Products

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Professional Thermostatic Conical Honey Melter

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- What are some dehumidification techniques for reducing honey moisture? Preserve Quality & Prevent Fermentation

- Why is Postharvest Drying Equipment critical in the stingless bee honey supply chain? Prevent Spoilage & Boost Quality

- Why is it necessary to equip honey processing workshops with industrial dehumidifiers? Prevent Spoilage and Souring

- What is the recommended maximum water content for honey? Expert Guide to Reducing Moisture and Preventing Spoilage

- What is the function of unglazed clay pots in the moisture reduction of honey? Preserving Bioactive Nutrients

- What are the benefits of using a honey dryer for honey production? Boost Yield & Quality

- How does the honey dryer operate to process honey? Master Gentle Moisture Removal for High-Quality Results

- What is the primary purpose of using industrial dehumidifiers in the pretreatment of stingless bee pot-pollen?