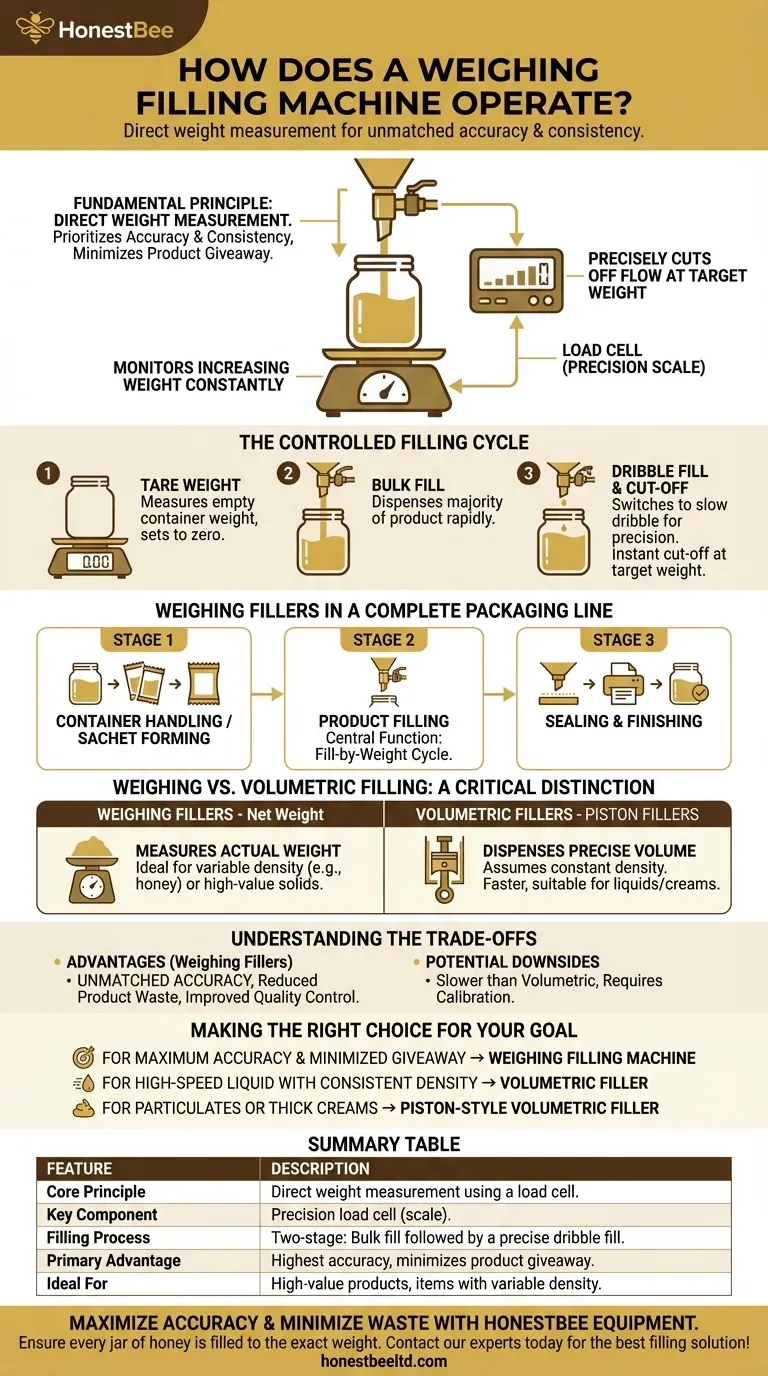

At its core, a weighing filling machine operates by dispensing product into a container that sits on a scale, or load cell. The machine's control system constantly monitors the increasing weight and precisely cuts off the product flow once a pre-set target weight is achieved, ensuring each container holds the exact same amount of product by mass.

The fundamental principle is direct weight measurement, which prioritizes accuracy and product consistency over filling speed or volume. This makes it the superior choice for high-value products or materials where density can vary, eliminating costly "product giveaway."

The Core Operational Principle: Fill-by-Weight

A weighing filling machine, also known as a net weight filler, is built around a simple but highly effective concept. It integrates a feeding mechanism with a precision scale to control the dispensing process.

The Role of the Load Cell

The load cell is the heart of the system. It is a highly sensitive electronic scale that the empty container is placed upon before the filling process begins.

The control system first measures the empty container's weight, known as the tare weight, and sets this value to zero. This ensures that only the product being added—the net weight—is measured.

The Controlled Filling Cycle

To maximize both speed and accuracy, most weighing fillers use a two-stage filling process.

First is the bulk fill, where the machine dispenses the majority of the product rapidly. As the weight approaches the target, the system automatically switches to a slow dribble fill (or trickle fill), adding the product gradually for maximum precision.

The "Cut-Off" Signal

The machine's controller continuously monitors the data from the load cell. The instant the target net weight is reached, it sends a signal to a valve or gate, immediately stopping the product flow. This instantaneous cut-off is what guarantees repeatable accuracy from one container to the next.

Weighing Fillers in a Complete Packaging Line

A weighing filler is typically one crucial component within a larger, automated packaging process. The entire sequence often looks like this.

Stage 1: Container Handling & Sachet Forming

The process begins with empty containers being fed onto the filling station. In some systems, like those for bags or sachets, the machine first unwinds and forms the packaging material itself.

Stage 2: Product Filling

The container is positioned on the load cell, and the fill-by-weight cycle begins as described above. This is the central function performed by the weighing filler.

Stage 3: Sealing and Finishing

Once filled, the container moves to the next station for sealing (e.g., heat sealing for sachets), batch number printing or embossing, and finally cutting and output as a finished product.

Weighing vs. Volumetric Filling: A Critical Distinction

It is vital to distinguish weighing fillers from another common type: volumetric fillers. They solve the same general problem but with a different philosophy.

Weighing Fillers (Net Weight)

These systems, as we've discussed, measure the actual weight of the product. They are ideal for products where density can change with temperature or batch variations (like honey) or for high-value solids where giving away even a gram per package is costly.

Volumetric Fillers (Piston Fillers)

A piston filler is a prime example of a volumetric system. It operates by drawing a precise volume of product from a hopper into a cylinder. A piston then pushes this exact volume out through a nozzle and into the container.

These machines are often faster and simpler but assume the product's density is constant. They are excellent for liquids, creams, and pastes where controlling volume is sufficient for consistency.

Understanding the Trade-offs

Choosing a filling technology requires balancing accuracy, speed, and cost.

The Case for Weighing Fillers

The primary advantage is unmatched accuracy. This directly translates into reduced product waste and improved quality control, which is essential for regulatory compliance and customer satisfaction.

Potential Downsides

Weighing fillers can be slower than their volumetric counterparts because the process involves settling time for the scale to get a precise reading. The load cells also require periodic calibration to maintain accuracy.

Making the Right Choice for Your Goal

Your specific product and production goals will determine the best technology.

- If your primary focus is maximum accuracy and minimizing product giveaway: A weighing filling machine is the definitive choice.

- If your primary focus is high-speed production of a liquid with consistent density: A volumetric filler, like a piston filler, may offer a more cost-effective solution.

- If your primary focus is handling products with particulates or thick creams: A piston-style volumetric filler is often specifically designed for this challenge.

Ultimately, understanding the core principle of direct weight measurement is the key to leveraging the power of a weighing filling machine effectively.

Summary Table:

| Feature | Description |

|---|---|

| Core Principle | Direct weight measurement using a load cell. |

| Key Component | Precision load cell (scale). |

| Filling Process | Two-stage: Bulk fill followed by a precise dribble fill. |

| Primary Advantage | Highest accuracy, minimizes product giveaway. |

| Ideal For | High-value products, items with variable density (e.g., honey, granules). |

Maximize your filling accuracy and minimize product waste with the right equipment. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-performance weighing and filling solutions. Ensure every jar of honey is filled to the exact weight, protecting your profits.

Contact our experts today to discuss the best filling machine for your operation!

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Semi-Automatic Pneumatic Bottle Capping Machine by HONESTBEE

- Automatic In-Line Round Bottle Labeling Machine

- Automatic Dual Sided In Line Labeling Machine

- Automatic Honey Frame Uncapper Machine for Beekeeping

People Also Ask

- How does an automated honey filling machine provide technical assurance? Scale Your Commercial Honey Distribution

- What are the key advantages of volumetric filling machines? Boost Packaging Speed & Flexibility

- How do automated honey filling machines and processing equipment contribute to market competitiveness? From Bulk to Brand

- What are the characteristics of a semi-automatic honey stick machine? Boost Your Packaging Efficiency

- How do automated industrial honey filling machines ensure compliance? Secure Food Safety and Global Market Access

- What economic benefits result from introducing automatic filling machines into apiculture? Unlock High-Value Markets.

- Which specific production challenges are addressed by high-precision honey filling machines? Solve Your Scaling Issues

- Why is honey packaging important? Protect Quality, Build Your Brand & Boost Sales