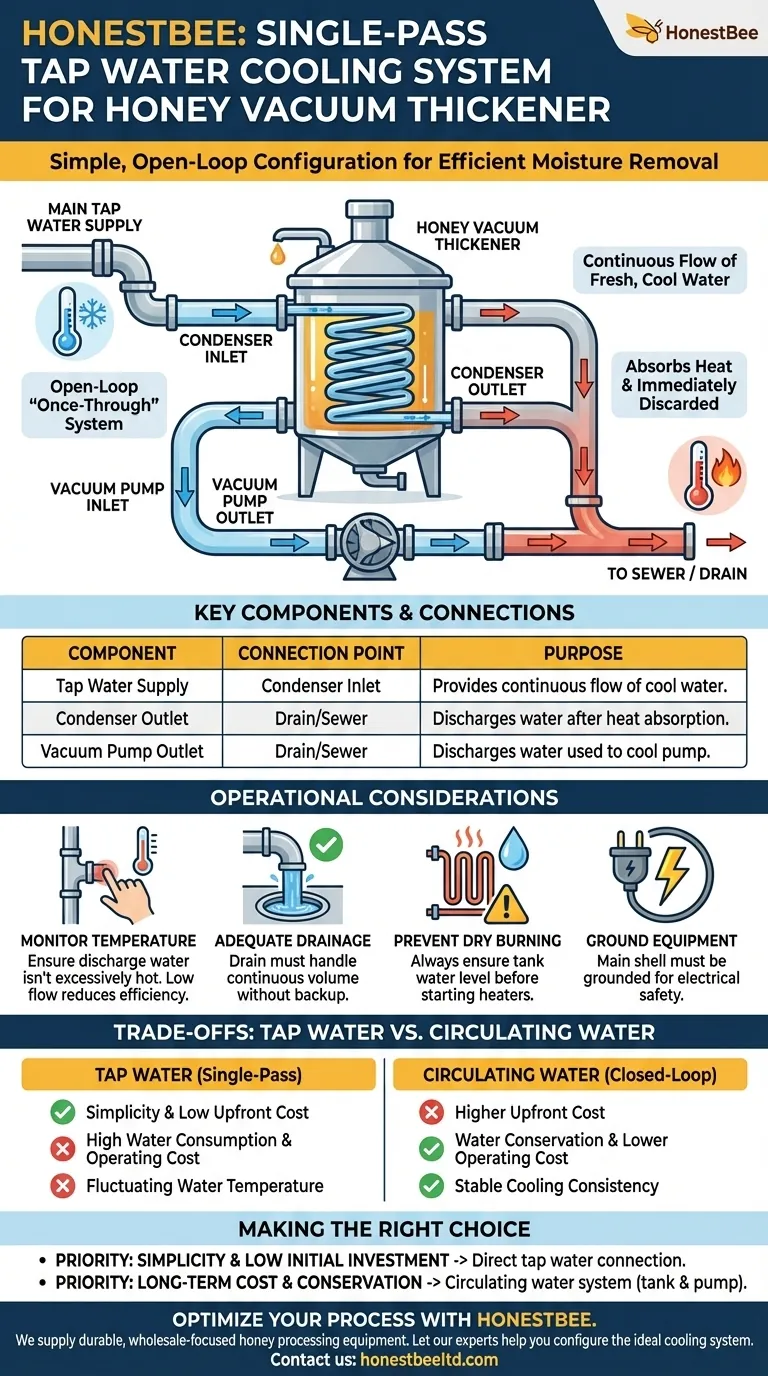

Configuring a honey vacuum thickener with tap water is a straightforward, single-pass process. You connect the main tap water pipe directly to the water inlet of the condenser. The water then flows through the system once, with the water outlets from both the condenser and the vacuum pump being connected directly to a sewer or drain for disposal.

The core principle of a tap water cooling setup is its simplicity: it's an open-loop, "once-through" system. Fresh, cool water is continuously supplied, absorbs heat from the condenser and pump, and is then immediately discarded, requiring no recirculation equipment.

Understanding the Tap Water Cooling Circuit

The primary function of the cooling system is to condense the water vapor evaporated from the honey, which is essential for maintaining a strong vacuum and efficiently removing moisture. A tap water setup accomplishes this with a direct and uncomplicated plumbing arrangement.

The Primary Connection: Condenser Inlet

Your main pressurized water source, the tap water pipe, connects to the designated water inlet on the condenser. This is the entry point for the entire cooling circuit.

The Dual Outlets to the Drain

After passing through the system, the warmed water must be expelled. Both the condenser's water outlet and the vacuum pump's water outlet are routed to the sewer. This continuous flow is critical for carrying heat away from the equipment.

Why It's a "Single-Pass" System

This configuration is fundamentally different from a closed-loop or circulating system. There is no water tank, and no pump is needed to recirculate the water. The municipal water pressure is sufficient to drive the flow through the equipment and out to the drain.

Key Operational Considerations

Properly managing the cooling circuit is vital for both the efficiency of the concentration process and the longevity of your equipment.

Monitor Cooling Water Temperature

Pay close attention to the temperature of the water exiting the system. If the discharge water feels excessively hot, it may indicate that the water flow rate is too low to effectively remove heat. This can reduce condensation efficiency and put a strain on the vacuum pump.

Ensure Adequate Drainage

Because water is constantly flowing and being discarded, your drain or sewer connection must be able to handle this continuous volume without backing up. Any obstruction can lead to spills and potential water damage.

Prevent Dry Burning

While not directly related to the plumbing, it is a critical safety interlock. Always ensure the water level in the preheating and concentration tank jackets is sufficient before starting. Operating the heaters without water will cause severe damage.

Ground the Equipment

For electrical safety, the main shell of the thickener must be properly grounded. This prevents the risk of electric shock, which is especially important in an environment where water is present.

Understanding the Trade-offs: Tap Water vs. Circulating Water

Choosing a cooling method involves balancing initial cost, operational expense, and environmental impact.

Simplicity and Lower Upfront Cost

The primary advantage of using tap water is its simplicity. It requires minimal extra equipment—no large storage tanks or recirculation pumps are needed, which significantly lowers the initial investment.

Water Consumption and Operating Cost

The main drawback is high water consumption. Since water is used once and discarded, the process can lead to substantial water bills over time, especially during long production runs.

Cooling Consistency

The temperature of tap water can fluctuate seasonally. This may affect the consistency of the condensation process, as warmer cooling water is less effective at creating a strong vacuum. A dedicated circulating system can provide more stable water temperatures.

Making the Right Choice for Your Goal

Your decision should be based on your operational scale, budget, and access to resources.

- If your primary focus is simplicity and minimal initial investment: The direct tap water connection is the most straightforward and cost-effective method to get started.

- If your primary focus is long-term operating cost and water conservation: A circulating water system with a tank and pump is the more sustainable and economical choice for frequent or large-scale production.

Ultimately, understanding these trade-offs allows you to select the cooling strategy that best aligns with your production needs and financial priorities.

Summary Table:

| Component | Connection Point | Purpose |

|---|---|---|

| Tap Water Supply | Condenser Inlet | Provides a continuous flow of cool water. |

| Condenser Outlet | Drain/Sewer | Discharges water after it absorbs heat. |

| Vacuum Pump Outlet | Drain/Sewer | Discharges water used to cool the pump. |

Optimize your honey processing with the right equipment from HONESTBEE.

We supply commercial apiaries and beekeeping equipment distributors with durable, wholesale-focused honey processing equipment, including vacuum thickeners. Our experts can help you configure the ideal cooling system—whether simple tap water or a more advanced recirculating setup—to maximize your efficiency and protect your investment.

Contact our team today to discuss your specific needs and get a quote: Get in Touch

Visual Guide

Related Products

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

People Also Ask

- What are some examples of honey packaging types? Choose the Best for Your Brand

- Why is the use of temperature-controlled storage tanks essential for honey? Secure Quality and Prevent Fermentation

- Why are platinum or quartz used for honey ash dishes? Ensure Forensic-Level Precision in Ash Content Analysis

- What advantages do modern honey harvesting techniques offer? Boost Yield and Purity with Specialized Machinery

- What improvements does a digital titration device offer for honey free acidity analysis? Boost Precision and Efficiency

- How do industrial-grade honey filling and processing equipment support beekeeping sustainability? Boost Hive Profits

- Why is a pH meter recommended for honey acidity titration? Ensure Precision in Honey Quality Analysis

- What is the function of Carrez reagents I and II in honey HMF testing? Ensure Accurate Chemical Analysis