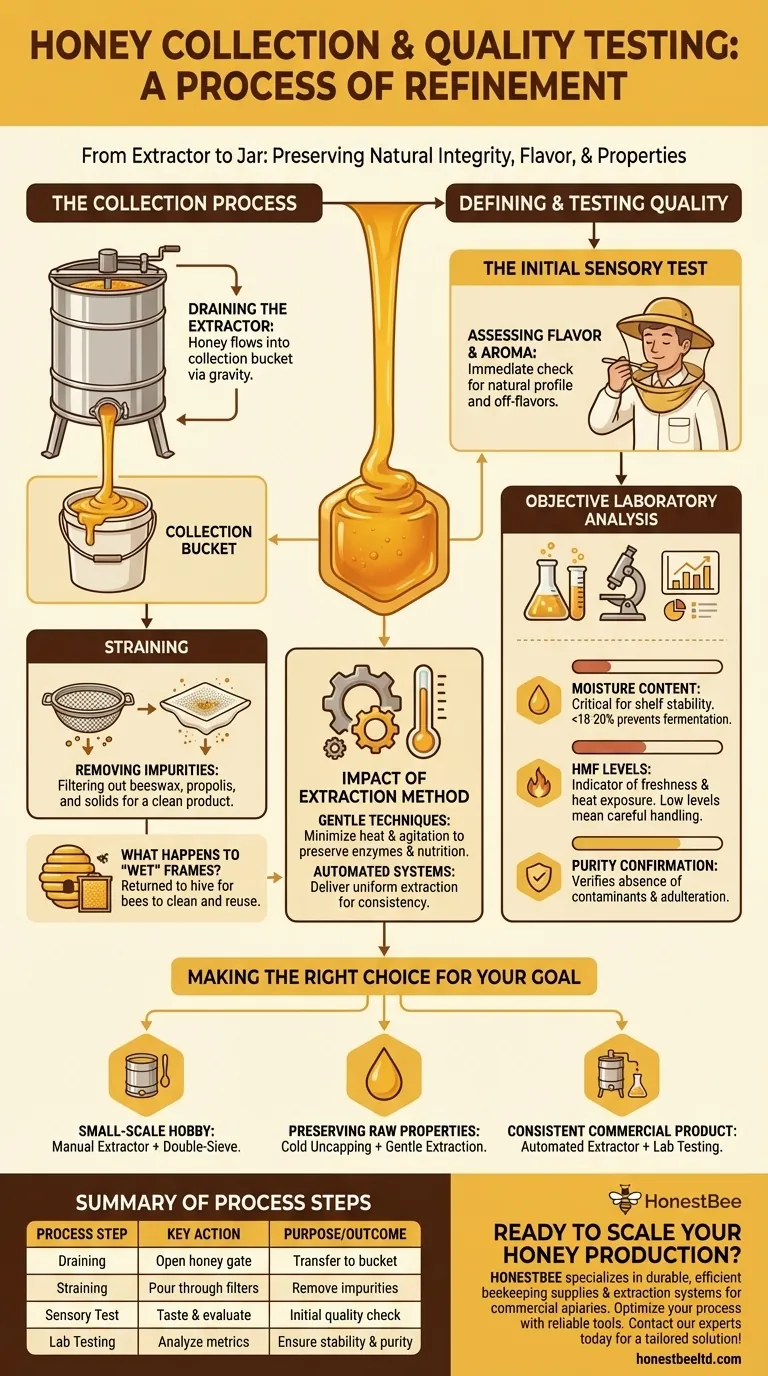

In short, once honey is spun out of the frames, it pools at the bottom of the extractor where a valve is opened to let it drain into a collection bucket. It is then filtered to remove impurities like beeswax, and its quality is assessed through sensory evaluation and, in more rigorous settings, objective laboratory testing.

The collection and testing of honey is a process of refinement. The goal is not merely to get honey into a jar, but to preserve its natural integrity by removing physical impurities while protecting its delicate flavor, aroma, and beneficial properties from damage.

The Collection Process: From Extractor to Bucket

The journey from the honeycomb to the final container involves several critical steps. Each one is designed to separate the pure honey from other hive materials without compromising its quality.

Draining the Extractor

After the frames are spun, the extracted honey flows down the walls of the extractor drum and accumulates at the bottom.

A valve at the base, often called a honey gate, is opened. Gravity does the work, allowing the thick, viscous honey to flow slowly into a food-grade bucket or tank positioned below.

The Critical Step of Straining

The raw honey coming from the extractor is not yet pure. It contains small particles of beeswax, propolis, and sometimes bee parts.

To achieve a clean final product, the honey is poured through a series of strainers or filters. These can range from simple double-sieve systems for hobbyists to fine mesh filters used in more advanced setups, ensuring all solid contaminants are removed.

What Happens to the "Wet" Frames?

The frames, now empty of honey but still coated in a sticky residue, are referred to as "wet."

These frames are typically returned to the hive. The bees will quickly clean every last drop of honey, preventing waste and giving them a valuable source of food to store or consume.

Defining and Testing Honey Quality

Ensuring high-quality honey goes far beyond simply making sure it's clean. Quality is a measure of purity, flavor, and the preservation of its natural state.

The Initial Sensory Test

The most immediate quality check is sensory. Beekeepers taste the honey, assessing its flavor profile, which can vary dramatically based on the nectar source.

This initial tasting confirms that the honey meets the expected standard and has not developed any off-flavors from fermentation or contamination.

The Impact of Extraction Method

The method of extraction directly influences quality. Gentle techniques, such as those used by a honey press or a carefully managed automated extractor, minimize heat and agitation.

This protection is vital for preserving the honey's delicate enzymes, flavors, and nutritional properties, which can be damaged by excessive heat or rough handling. Automated systems also deliver a uniform extraction speed, contributing to a more consistent product.

Objective Quality Metrics: What Professionals Measure

For commercial producers or those seeking certification, sensory tests are not enough. Objective laboratory analysis provides a true measure of quality.

Key metrics include:

- Moisture Content: This is the most critical factor for shelf stability. Honey with a moisture content above 18-20% is at risk of fermenting.

- HMF (Hydroxymethylfurfural): HMF is a compound that forms when honey is heated or has aged. Low HMF levels indicate fresh honey that has been handled carefully without excessive heat.

- Purity: Lab tests can confirm the honey is free from contaminants and has not been adulterated with other sugars.

Understanding the Trade-offs

Different goals require different approaches, and every method involves a trade-off between efficiency, cost, and the final quality of the honey.

Manual vs. Automated Extraction

Manual, hand-crank extractors are cost-effective and ideal for hobbyists. However, the extraction speed can be inconsistent, potentially leading to variations in how much honey is extracted.

Automated extractors provide uniform speed and are far more efficient for larger operations. This consistency helps in producing a standard product, which is essential for building a reputable brand, but comes at a higher initial cost.

Heat Application During Uncapping

To remove the wax cappings from a frame, beekeepers often use heated uncapping knives. While effective, excessive heat can begin to degrade the honey's delicate enzymes before it even reaches the extractor.

Using cold knives or mechanical uncappers avoids this risk entirely, better preserving the honey in its raw state, though these methods can be slower or more labor-intensive.

Making the Right Choice for Your Goal

Your approach to collection and testing should align directly with what you want to achieve with your honey.

- If your primary focus is small-scale hobby production: A manual extractor followed by a simple double-sieve for straining is a perfectly effective and economical method.

- If your primary focus is preserving raw honey's delicate properties: Prioritize methods that use zero or very low heat, such as a cold uncapping knife and gentle extraction techniques.

- If your primary focus is a consistent commercial product: Invest in an automated extractor for efficiency and consider sending samples for laboratory testing to verify moisture content and purity.

Ultimately, high-quality honey is the direct result of careful, deliberate choices made at every step of the process.

Summary Table:

| Process Step | Key Action | Purpose/Outcome |

|---|---|---|

| Draining | Open honey gate at extractor base | Transfer honey to a collection bucket via gravity |

| Straining | Pour honey through mesh/sieve filters | Remove wax, propolis, and other solid impurities |

| Sensory Test | Taste and evaluate flavor/aroma | Initial quality check for off-flavors or fermentation |

| Lab Testing | Analyze moisture, HMF, and purity | Ensure shelf stability, freshness, and no adulteration |

Ready to scale your honey production with professional-grade equipment?

As HONESTBEE, we specialize in supplying durable, efficient beekeeping supplies and extraction systems to commercial apiaries and distributors. Our wholesale-focused operations ensure you get the reliable tools needed for consistent, high-quality honey output. Let's discuss how our equipment can optimize your process—contact our experts today for a tailored solution!

Visual Guide

Related Products

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- Natural Wood Honey Dipper for Tea Coffee and Desserts

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

People Also Ask

- What is the purpose of a honey press? Maximize Yield for Small-Scale Beekeeping

- What are the material advantages of using a stainless steel honey press? Ensure Pure, Lead-Free Honey Extraction

- What are the steps to operate a bucket honey press? Maximize Your Honey Yield with Simple Mechanical Force

- What are the key features of a honey press? Maximize Yield with Durable, Efficient Extraction

- What is the role of large harvesting dishes in top-bar hives? Essential Tools for Efficient Honey Collection