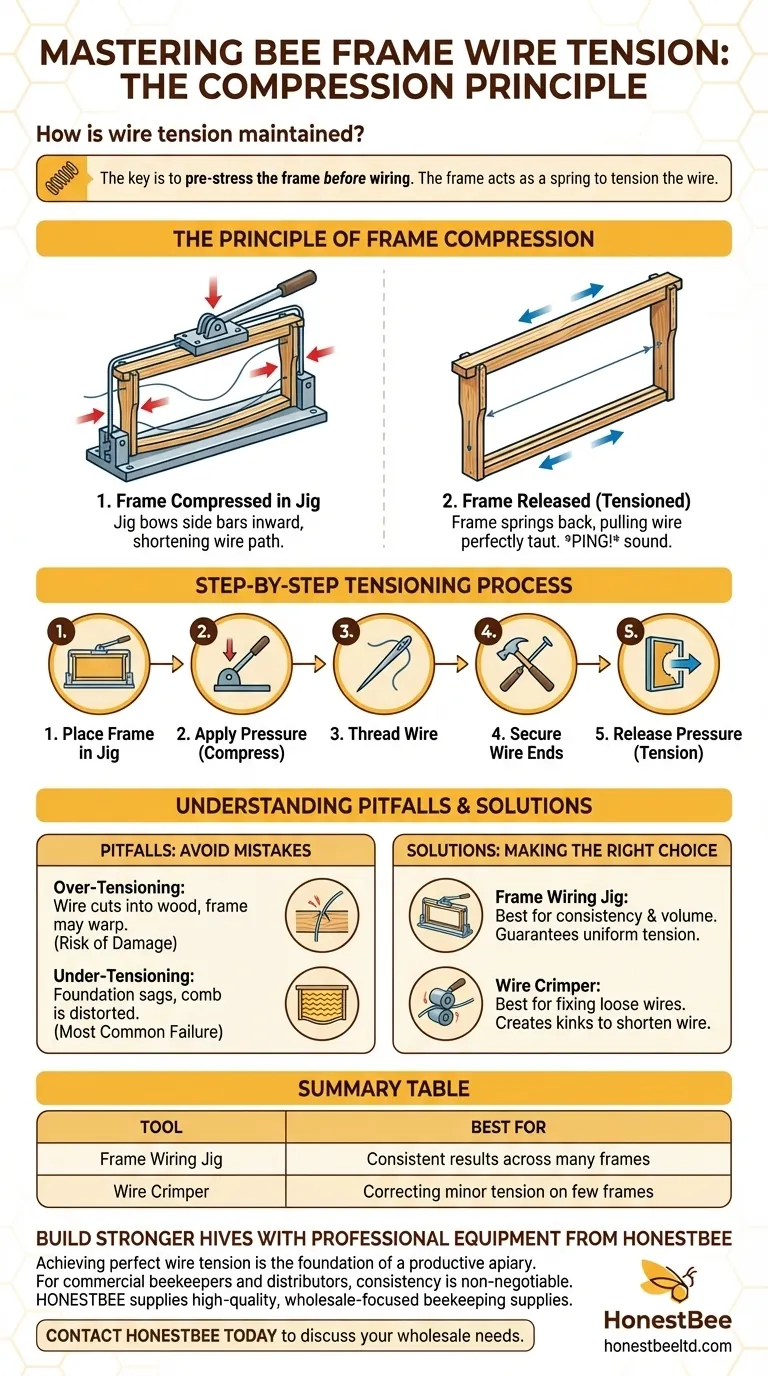

Achieving proper wire tension in a bee frame is accomplished by using the frame itself as a spring. The process involves temporarily compressing the frame in a specialized jig, which bows the side bars inward. After the wire is threaded and secured, the frame is released from the jig, and as it springs back to its natural shape, it pulls the wire perfectly taut.

The key to consistent wire tension is not to pull the wire tight, but to pre-stress the frame before wiring. The frame does the work of tensioning the wire for you when it is released.

The Principle of Frame Compression

To create strong, durable comb, the wire support system must be tight. A loose wire offers no support, leading to foundation that sags and breaks under the weight of honey or the heat of the hive.

Why Tension Is Critical

Properly tensioned wires provide the structural skeleton for the wax foundation. This rigidity prevents the foundation from warping or "blowing out" during honey extraction.

More importantly, it ensures the bees build straight, even comb within the confines of the frame, which is essential for easy hive inspections and management.

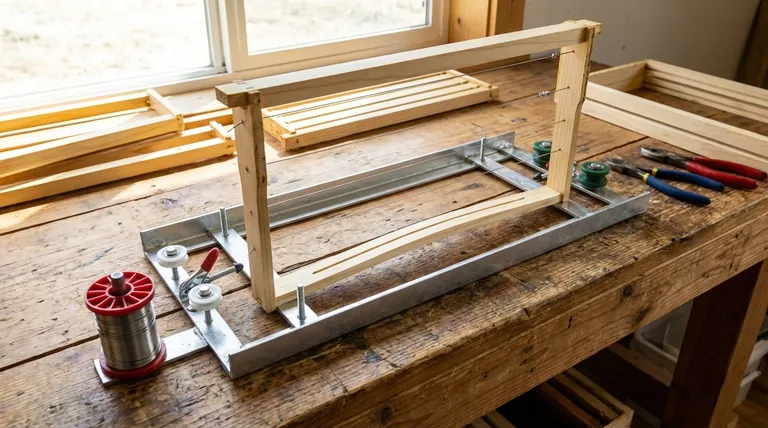

The Mechanics of a Wiring Jig

The most common tool for this job is a frame wiring jig or wiring board. This simple device has a base to hold the frame and a block or lever positioned to press down on the frame's bottom bar.

When you apply pressure, the bottom bar is pushed slightly downward. Because the side bars are fixed at the top, this pressure forces them to bow inwards, shortening the distance the wire needs to travel.

The Step-by-Step Tensioning Process

- Place the frame into the wiring jig.

- Apply pressure to the jig's lever, compressing the frame. You will see the side bars flex slightly.

- Thread the wire through the eyelets or holes in the side bars.

- Secure the wire by wrapping it tightly around the starting and ending nails or pins.

- Release the pressure on the jig. The side bars will spring back to their straight, parallel position, instantly tightening the wire. A properly tensioned wire will make a low-pitched "ping" or hum when plucked.

Understanding the Trade-offs and Pitfalls

While the process is straightforward, achieving the right amount of tension requires avoiding a few common mistakes.

The Risk of Over-Tensioning

It is possible to make the wire too tight. Excessive tension can cause the wire to slowly cut into the soft wood of the frame over time, causing it to lose its tautness.

In extreme cases, especially with poor-quality frames, over-tensioning can even warp or break the frame's joints.

The Consequence of Under-Tensioning

This is the most common failure. If the wire is not sufficiently taut, it fails its primary purpose. The wax foundation will sag in the heat, resulting in distorted, uneven comb that is difficult for the beekeeper to manage and for the bees to use efficiently.

Using a Wire Crimper for Adjustments

A secondary tool called a wire crimper can be used to fix slightly loose wires. This hand tool rolls along the wire, creating small kinks. Each kink shortens the wire's length slightly, increasing its overall tension. It is excellent for minor adjustments but is not a substitute for proper initial tensioning.

Making the Right Choice for Your Operation

Your approach to wiring should match your goals and the scale of your beekeeping.

- If your primary focus is consistency and efficiency: Invest in a dedicated frame wiring jig. This is the only way to guarantee uniform, reliable tension across dozens or hundreds of frames.

- If your primary focus is correcting a few loose frames: A simple wire crimper is a cost-effective tool for salvaging frames with slightly sagging wires.

- If your primary focus is starting with minimal equipment: You can attempt to manually flex the frame while wiring, but be prepared for inconsistent results and the high likelihood of sagging foundation.

Building strong frames is the essential first step toward a productive and manageable beehive.

Summary Table:

| Tool | Primary Function | Best For |

|---|---|---|

| Frame Wiring Jig | Compresses frame to pre-stress it before wiring | Beekeepers needing consistent, reliable results across many frames |

| Wire Crimper | Creates kinks to shorten and tighten an already-installed wire | Correcting minor tension issues on a few existing frames |

Build Stronger Hives with Professional Equipment from HONESTBEE

Achieving perfect wire tension is the foundation of a productive apiary. For commercial beekeepers and equipment distributors, consistency and durability are non-negotiable. HONESTBEE supplies the high-quality, wholesale-focused beekeeping supplies and equipment you need to operate efficiently at scale.

Let us help you equip your operation for success. Contact HONESTBEE today to discuss your wholesale needs.

Visual Guide

Related Products

- HONESTBEE Professional Frame Wiring Board and Jig

- Professional Bee Frame Wiring Tool with Integrated Tensioning System by HONESTBEE

- HONESTBEE Durable Frame Wiring Board with Integrated Tensioner

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional 3-Bar Frame Grip with Integrated Hive Tool

People Also Ask

- How do standardized beehive frames contribute to management? Unlock Scalable Success for Commercial Apiaries

- What are the advantages of plastic beehive frames? Enhance Durability and Efficiency in Your Apiary

- What role do standardized wooden frames play in bee colony performance evaluation? Precision Tools for Beekeeping Data

- How do hollow frames with grid subdivisions assist in measuring brood areas? Achieve 99% Precision in Bee Data

- What are the specific functions of specialized breeding cages and wax frames? Enhance Experimental Bee Sample Precision

- What types of damage on bee frames indicate they can be cleaned for reuse? Save Costs with Proper Frame Restoration

- What is the technical value of using a standard wire frame grid? Unlock Precision Measurement in Colony Management

- What is the function of foundation frames for newly mated queens? Accelerate Egg-Laying and Colony Growth