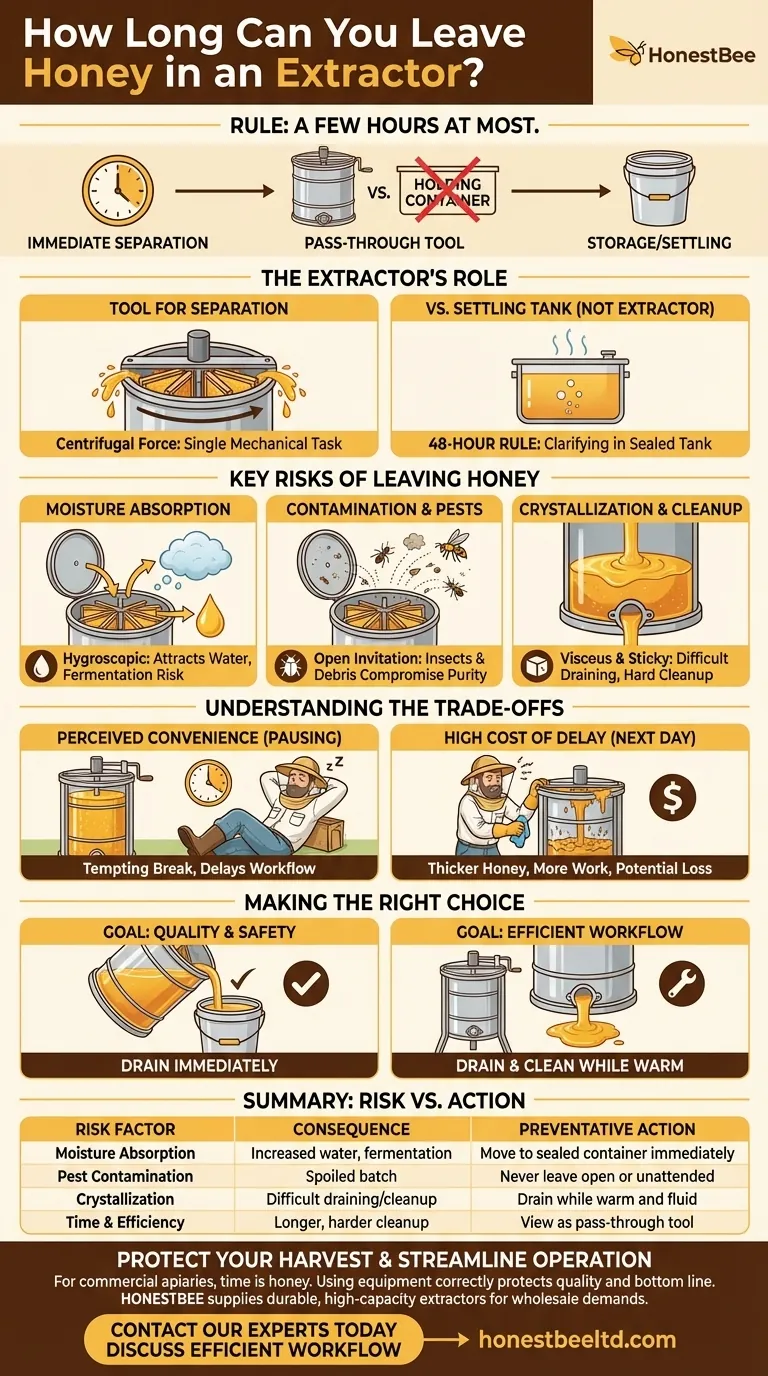

As a rule, you should not leave honey in an extractor for more than a few hours at most. The extractor's purpose is for immediate separation, not for storage or settling. Leaving honey in the machine for an extended period, such as overnight, exposes it to air, pests, and temperature changes that can degrade its quality and make your cleanup process significantly more difficult.

The core principle is to view your extractor as a pass-through tool, not a holding container. The goal is to move the honey from the frames, through the extractor, and into a sealed, food-safe bucket or settling tank as quickly and efficiently as possible.

The Extractor's Role in Your Workflow

To understand why honey shouldn't be left in an extractor, it's critical to distinguish its function from other beekeeping equipment. Its role is specific and temporary.

A Tool for Separation, Not Storage

An extractor uses centrifugal force to spin honey out of the uncapped honeycomb cells. Its design—a large drum with a spinning cage and a gate at the bottom—is optimized for this single mechanical task. It is not sealed against the environment.

The Extractor vs. The Settling Tank

A common point of confusion is the "48-hour rule," which applies to a settling tank, not an extractor. After extraction, honey is poured into a sealed tank for 24-48 hours to allow fine air bubbles and wax particles to rise to the surface, clarifying the final product. An extractor is the step before this process.

Key Risks of Leaving Honey in the Extractor

Leaving honey in an open or unsealed extractor introduces several preventable problems that can compromise your harvest.

Absorption of Moisture

Honey is hygroscopic, meaning it naturally absorbs moisture from the surrounding air. If left in an open extractor in a humid environment, the honey's water content can rise, creating a risk of fermentation and spoilage.

Contamination and Pests

An extractor left with honey is an open invitation to ants, wasps, and other insects. It's also susceptible to contamination from dust and airborne debris, compromising the safety and purity of your honey.

Crystallization and Cleanup

Honey begins to cool and thicken as soon as it leaves the warmth of the hive. If left in the extractor, it will become more viscous and may even begin to crystallize, making it extremely difficult to drain completely through the honey gate and creating a difficult, sticky cleanup process.

Understanding the Trade-offs

While it might seem convenient to pause the process, the risks associated with delay almost always outweigh the benefits.

The "Convenience" of Pausing

A beekeeper might be tempted to leave honey in the extractor overnight due to fatigue or time constraints after a long day of pulling frames from the hives. This seems like a simple way to break the work into two days.

The High Cost of Delay

This perceived convenience comes at a high cost. The next day, you will face honey that is thicker, harder to drain, and potentially contaminated. The time you saved the night before will be lost dealing with these preventable issues.

Making the Right Choice for Your Goal

Your approach should be dictated by your primary goal, whether it's maximizing quality or streamlining your process.

- If your primary focus is honey quality and safety: Drain the extractor immediately after each batch is spun to move the honey into a sealed, food-grade settling tank or bucket.

- If your primary focus is an efficient workflow: Drain and clean your extractor while the residual honey is still warm and fluid, which makes the entire process faster and simpler.

Treating your extractor as a temporary pass-through tool is the key to preserving the quality of your harvest and the longevity of your equipment.

Summary Table:

| Risk Factor | Consequence | Preventative Action |

|---|---|---|

| Moisture Absorption | Increased water content, risk of fermentation | Move honey to a sealed container immediately |

| Pest Contamination | Ants, wasps, and debris can spoil the batch | Never leave an extractor unattended or open |

| Crystallization | Honey thickens, making draining and cleanup difficult | Drain extractor while honey is still warm and fluid |

| Time & Efficiency | Perceived convenience leads to a longer, harder cleanup | View the extractor as a pass-through tool, not for storage |

Protect Your Harvest and Streamline Your Operation

For commercial apiaries and distributors, time is honey. Using the right equipment correctly is essential for protecting your product's quality and your operation's bottom line. HONESTBEE supplies durable, high-capacity extractors and the full suite of beekeeping supplies designed for the demands of wholesale operations.

Contact our experts today to discuss how our equipment can help you maintain a fast, efficient, and quality-focused honey harvesting workflow.

Visual Guide

Related Products

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

People Also Ask

- How does specialized honey harvesting machinery ensure efficiency? Scale Your Forest Honey Production

- What are the advantages of centrifugal honey extractors? Boost Commercial Yield Through Comb Preservation

- How does professional honey extraction equipment improve quality? Elevate Your Apiary's Market Value and Purity

- What are the technical advantages of using centrifugal honey extractors? Maximize Yield & Preserve Your Combs

- What equipment is typically used for honey extraction? Professional Tools for High-Yield Harvesting

- What is the function of industrial-grade centrifuges in honey extraction? Boost Apiary Efficiency and Honey Purity

- What is the primary function of a Centrifugal Honey Extractor? Boost Your Apiary's Yield and Efficiency

- How do centrifuge honey extractors operate? Maximize Your Honey Harvest with Efficient Centrifugal Extraction