Before its first use, your new honey press must be washed with a warm, food-safe detergent solution. This essential first step is not for general tidiness; it is a critical process to remove industrial contaminants like machining oils, metal dust, and welding residues left over from the manufacturing process. A thorough cleaning ensures these substances do not contaminate your first honey harvest.

Cleaning a new press is fundamentally different from cleaning it after use. The initial goal is to eliminate industrial residues to ensure food safety, while subsequent cleanings focus on removing wax and honey.

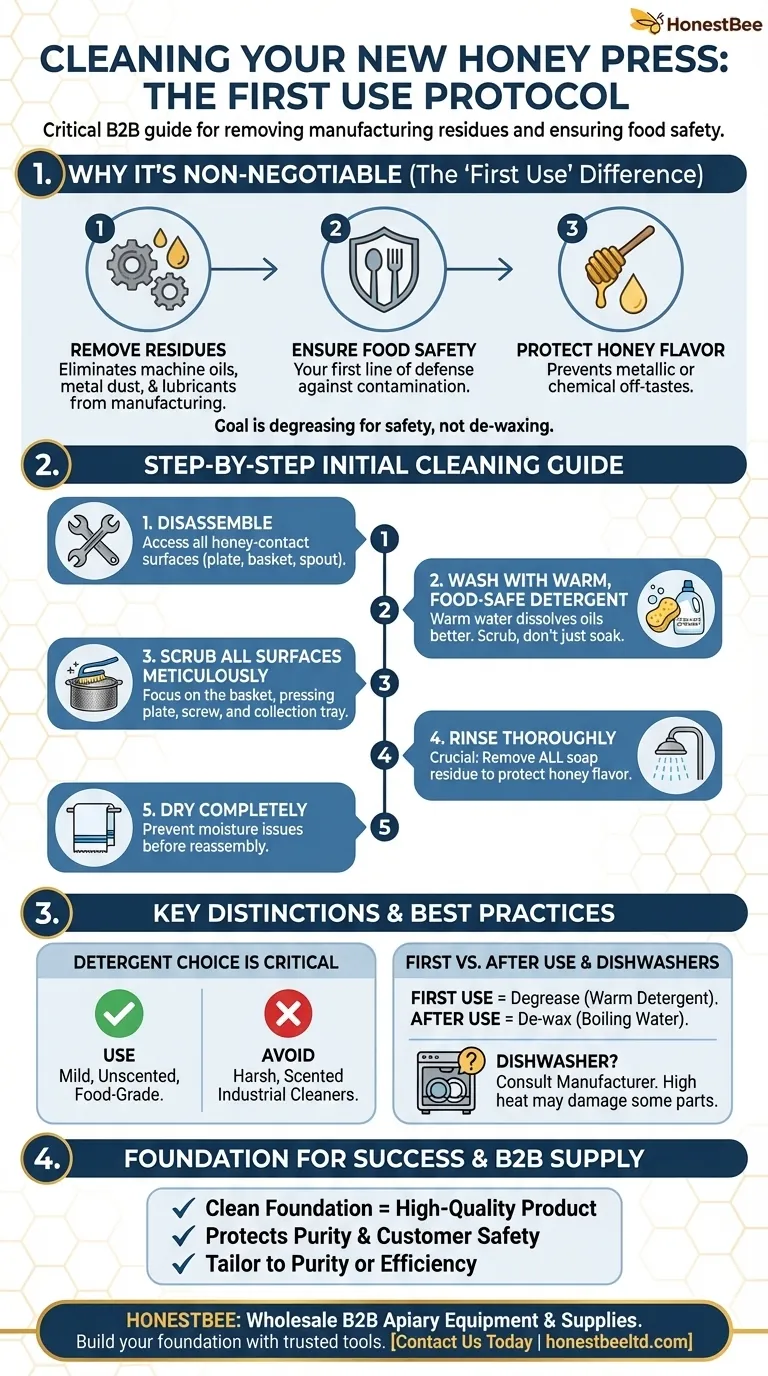

Why a 'First Use' Clean is Non-Negotiable

A honey press arrives from the factory, not the apiary. Understanding the necessity of this initial clean protects your product, your customers, and your investment.

Removing Manufacturing Residues

During production, components are cut, welded, and polished. This leaves a fine layer of machine oils, lubricants, and metal dust. These substances are not food-safe and will impart off-flavors and contaminants into your honey if not removed.

Ensuring Food Safety

Your responsibility as a food producer begins the moment the honey leaves the comb. Treating the press as food-contact equipment from the very start establishes a critical food safety protocol. This first wash is your first line of defense against contamination.

Protecting Your Honey Harvest

The delicate flavor profile of honey is easily tainted. A press that has not been properly degreased can introduce a metallic or chemical taste, potentially ruining an entire batch of otherwise perfect honey.

The Initial Cleaning Process: A Step-by-Step Guide

Follow this procedure to prepare your honey press for its first batch. Most presses are designed for easy cleaning.

Step 1: Disassemble the Press

Before washing, take the press apart as much as possible. This typically involves removing the pressing plate, the steel basket or cage, and the spout. This allows you to access every surface that will contact your honey.

Step 2: Wash with Detergent and Warm Water

Use a food-safe detergent and warm water to scrub all components. Warm water is more effective than cold at dissolving and lifting the oils used in manufacturing. Focus on scrubbing, not just soaking.

Step 3: Pay Attention to All Surfaces

Meticulously clean the inside and outside of the basket, both sides of the pressing plate, the screw mechanism, and the collection tray and spout. These are all critical points of contact.

Step 4: Rinse Thoroughly with Clean Water

This step is as important as washing. Rinse every component with clean, clear water until all traces of detergent are gone. Soap residue can be just as detrimental to your honey's flavor as machine oil.

Step 5: Dry Completely

Allow all parts to air dry completely or dry them with a clean, lint-free cloth. Trapped moisture can lead to issues later. Once dry, you can reassemble the press.

Understanding the Key Distinctions

Not all cleaning is the same. Recognizing the differences in detergents and procedures will ensure you use the right method at the right time.

Detergent Choice is Critical

Do not use harsh industrial cleaners or scented dish soaps. Always opt for a mild, unscented, food-grade detergent. The goal is to clean without leaving behind any chemical residue of your own.

The "After Use" Cleaning Method

Cleaning a press after it has been used for honey and wax is a different task. This process involves using boiling water to melt and soften residual beeswax from the cage, followed by scraping. This is for wax removal, not for degreasing a new machine.

The Dishwasher Question

While some durable stainless steel components like the mesh basket may be dishwasher safe, always consult the manufacturer's instructions first. The high heat of a dishwasher can be effective, but it may not be suitable for all parts of your press.

Preparing Your Press for Success

Your approach to cleaning can be tailored to your specific priorities.

- If your primary focus is absolute purity: Disassemble every possible component and use a designated food-grade sanitizer after the initial detergent wash and rinse.

- If your primary focus is speed and efficiency: Concentrate your most vigorous scrubbing on the direct honey-contact surfaces—the basket, plate, and spout—but ensure you thoroughly rinse the entire unit.

A pristine press is the foundation of a high-quality product.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1 | Disassemble the press | Access all honey-contact surfaces for thorough cleaning. |

| 2 | Wash with warm, food-safe detergent | Remove machining oils, lubricants, and metal dust from manufacturing. |

| 3 | Scrub all surfaces meticulously | Ensure no contaminants remain on the basket, plate, or spout. |

| 4 | Rinse thoroughly with clean water | Eliminate all detergent residue to protect honey flavor. |

| 5 | Dry completely before reassembly | Prevent moisture-related issues and prepare for first use. |

Protect your honey's purity and your customers' safety with equipment you can trust. A properly cleaned press is just the first step. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-quality, durable honey presses and other essential beekeeping supplies through our wholesale-focused operations. Let us help you build a foundation for a superior product. Contact HONESTBEE today to discuss your equipment needs and wholesale pricing.

Visual Guide

Related Products

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

People Also Ask

- How can you smooth out the sharp edges of the honey press? A Guide to Safe, Hygienic Preparation

- What is the primary function of a honey screw press? Maximize Yield with Advanced Cold Press Separation Technology

- What is the recommended temperature for using a honey press? Optimize Your Extraction Efficiency

- Why is it inadvisable to line the press basket with a muslin bag or nylon sock? Protect Your Equipment and Workflow

- How does industrial-grade honey pressing machinery contribute to large-scale liquid honey production? Maximize Your Yield

- What is the function of the inner bucket in the honey press? Master the Art of Effective Honey Filtration

- How does the honey press filter honey? Master Efficient Extraction and Impurity Removal

- What is the mechanism of action for a manual Honey Presser? Maximize Your Yield in Transitional Beekeeping