To ensure uniform wax sheets, the dipping board must be held perfectly straight and horizontal both during and immediately after each dip into the molten wax. This precise handling allows excess wax to flow off the board smoothly and evenly, which is the single most critical factor in creating a sheet of consistent thickness.

The core principle is not just about keeping the board level, but about mastering gravity. A perfectly horizontal board allows gravity to pull excess wax off uniformly, creating a consistent "grain" in the sheet that is essential for preventing defects and ensuring successful milling.

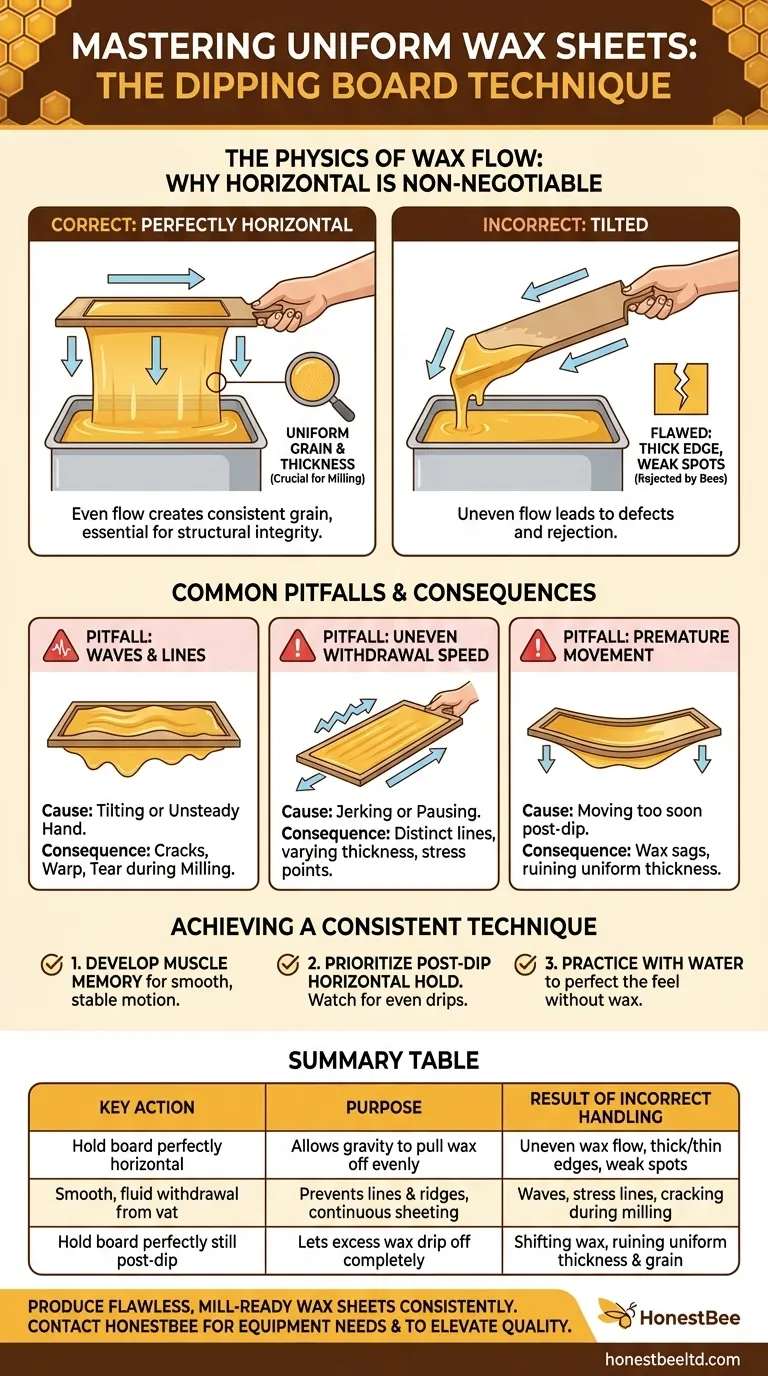

The Physics of Wax Flow: Why Horizontal is Non-Negotiable

The quality of a finished wax sheet is determined in the few seconds after it leaves the vat. The way the molten wax behaves in this short window is governed entirely by technique.

The Critical Role of Gravity

Gravity is the force that removes excess wax from the board. When the board is held perfectly horizontal, gravity acts equally across its entire bottom edge, pulling a uniform "curtain" of wax downward.

This even flow is what produces a flat sheet with a consistent thickness from top to bottom and side to side.

The Consequence of Tilting

If the board is tilted even slightly, gravity will cause the molten wax to run towards the lowest point. This creates a thick edge on one side and a thin, weak area on the other.

This imbalance results in a defective sheet that is difficult to handle and may be rejected by bees.

Establishing a Uniform Wax "Grain"

The smooth, directional flow of cooling wax orients its crystalline structure, creating a uniform "grain" similar to the grain in a piece of wood.

This consistent grain is not just for appearance; it imparts structural integrity to the sheet. A uniform grain is absolutely essential for the sheet to be properly accepted and milled by the foundation-making rollers.

Common Pitfalls and Their Consequences

Minor mistakes in handling the dipping board lead to significant flaws in the final product. Understanding these pitfalls is key to avoiding them.

Pitfall: Waves and Lines

Waves, lines, or ridges in the sheet are a direct result of an uneven flow of wax. This is typically caused by tilting the board or an unsteady hand during the crucial moments after withdrawal.

These are not merely cosmetic defects. They represent points of varying thickness and internal stress, which can cause the sheet to crack, warp, or tear during the milling process.

Pitfall: Uneven Withdrawal Speed

Jerking the board out of the wax or pausing during withdrawal disrupts the smooth sheeting action of the molten wax. This hesitation creates a distinct line where wax has begun to solidify at a different rate.

The motion into and out of the vat must be fluid and deliberate to prevent these imperfections.

Pitfall: Premature Movement

After withdrawing the board, it must be held perfectly still and horizontal until the excess wax has finished dripping off. Moving it or setting it down too soon will cause the still-liquid surface layer to shift and sag, ruining the uniform thickness you worked to create.

Achieving a Consistent Technique

Mastering this process is about developing muscle memory for a smooth, stable, and level motion.

- For the highest quality sheets for milling: Your absolute priority is the post-dip horizontal hold. This is what creates the uniform grain necessary for the rollers to emboss the foundation pattern correctly.

- If you are struggling with waves or thick edges: Focus on keeping the board perfectly still and level the instant it clears the vat. Watch the drips; they should form evenly along the entire bottom edge.

- If you are new to the process: Practice the motion without wax. Dip the dry board in water and observe how the water flows off, using it as a guide to perfect your horizontal hold and smooth withdrawal.

Ultimately, disciplined and precise handling of the dipping board is the foundational skill upon which all high-quality wax sheet production is built.

Summary Table:

| Key Action | Purpose | Result of Incorrect Handling |

|---|---|---|

| Hold board perfectly horizontal during/after dip | Allows gravity to pull wax off evenly, creating uniform thickness | Uneven wax flow, causing thick/thin edges and weak spots |

| Smooth, fluid withdrawal from vat | Prevents lines and ridges by ensuring a continuous sheeting action | Waves and stress lines that can lead to cracking during milling |

| Hold board perfectly still post-dip | Lets excess wax drip off completely before the surface solidifies | Shifting liquid wax, ruining the uniform thickness and grain |

Produce flawless, mill-ready wax sheets consistently. The precision of your dipping technique is fundamental to your operation's success. At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the high-quality, durable equipment needed to master this process. Our wholesale-focused operations ensure you get the reliable tools that support perfect technique and maximize your foundation production yield.

Contact our expert team today to discuss your equipment needs and elevate your wax sheet quality.

Visual Guide

Related Products

- Beeswax Foundation Sheets Beehive Foundation for Wholesale

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Notebook Style Beeswax Foundation Mould Wax Foundation Mold

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

People Also Ask

- Why is beeswax foundation considered an essential consumable? Maximize Hive Productivity and Honey Yields

- Why are beeswax foundations critical for honey yield? Boost Your Commercial Apiary's Production Efficiency Today

- What are the advantages of using beeswax foundation in a beehive? Boost Honey Yields and Hive Purity

- What structural and practical benefits do beeswax foundations provide? Boost Your Hive Stability and Honey Yield

- How is beeswax foundation installed and reinforced in a frame? Master Durable Comb Setup for Your Apiary