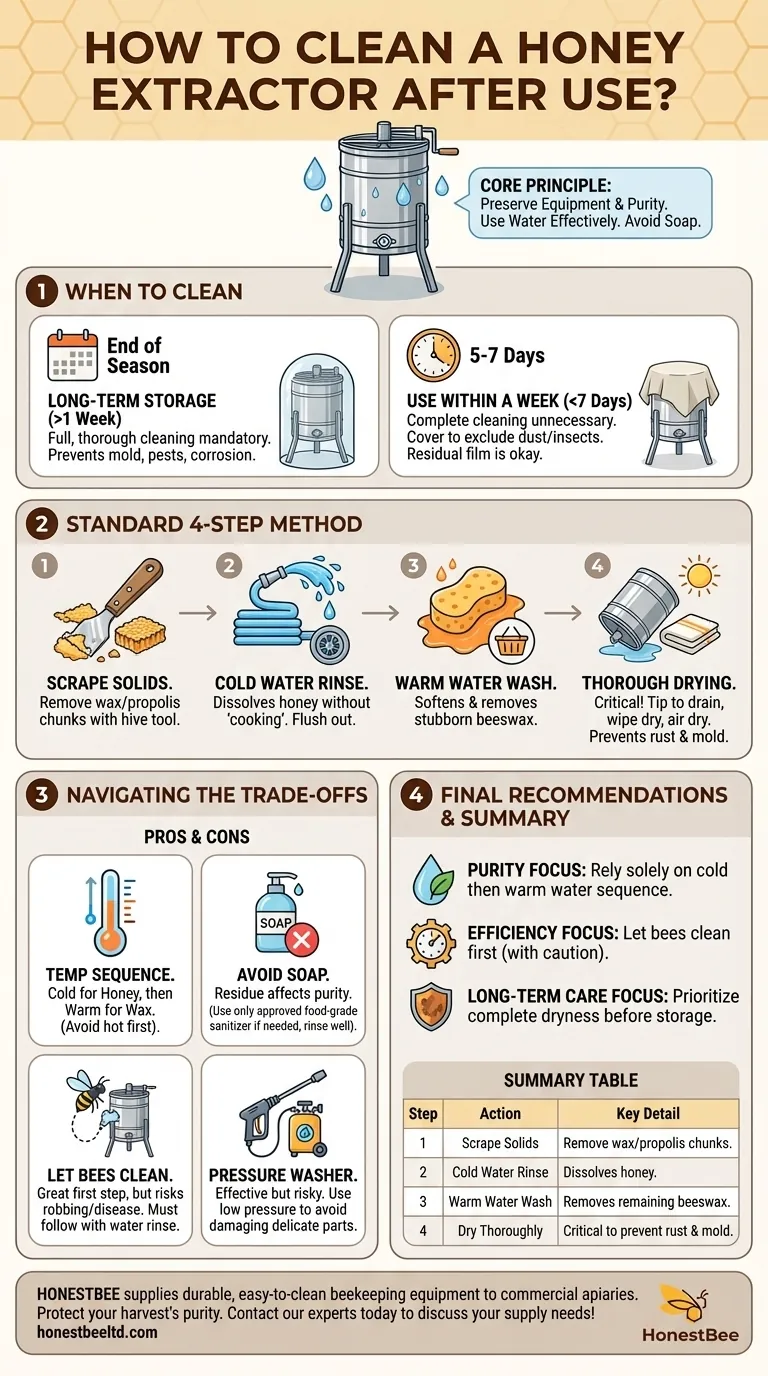

At its core, cleaning a honey extractor is a straightforward process focused on removing residual honey and wax. The most effective method involves an initial rinse with cold water to dissolve the bulk of the honey, followed by a wash with warm water to remove any remaining wax, and then allowing it to dry completely.

The primary goal of cleaning your extractor is not just tidiness, but the preservation of your equipment and the purity of your next honey harvest. The critical principle is to use water effectively and avoid any cleaning agents, like soap, that could leave residue and contaminate future batches.

When to Clean Your Extractor

The timing of your cleaning depends entirely on when you plan to use the extractor again.

For Long-Term Storage

A full, thorough cleaning is mandatory at the end of the harvesting season or any time the extractor will be stored for more than a week. This prevents mold, attracts pests, and protects the machinery from corrosion.

For Use Within a Week

If you plan to extract more honey within the next 5-7 days, a complete cleaning is often unnecessary. Simply cover the extractor to keep out dust and insects. The residual honey film will not harm the next batch.

The Standard Cleaning Method: Step-by-Step

This manual method using water is the most common and safest approach for cleaning your extractor.

Step 1: Scrape Away Solids

Using a spatula or a hive tool, scrape out any significant chunks of beeswax or propolis from the interior drum and the baskets or frames. This makes the washing process much easier.

Step 2: The Initial Cold Water Rinse

Position the extractor so the honey gate can drain into a bucket or floor drain. Use a hose to spray the interior with cold water.

Cold water is highly effective at dissolving honey without "cooking" it onto the metal surfaces. Let the water sit for a few minutes to dissolve the sticky film, then give it a good rinse, flushing the honey-water mixture out the gate.

Step 3: The Main Wash with Warm Water

After the cold rinse, use warm water to wash the interior. Warm water is excellent for softening and removing any remaining bits of stubborn beeswax. You can use a soft cloth or sponge to wipe down the surfaces.

For a deeper clean, especially on an electric model, you may need to disassemble the baskets or racks to clean them individually.

Step 4: Thorough Rinsing and Drying

Perform a final rinse to ensure all debris is gone. Afterward, it is absolutely critical to dry the extractor completely. Tip it on its side or upside down to drain fully, and then wipe any remaining moisture with a clean, dry cloth.

Air drying in the sun is also a great option. Complete dryness prevents rust on metal parts and mold growth during storage.

Cleaning the Exterior

The outside of the machine rarely needs more than a simple wipe-down. Use a damp cloth to clean off any honey drips, fingerprints, or dust.

Understanding the Trade-offs

Beekeepers debate several aspects of cleaning. Understanding the pros and cons will help you make the right choice.

The Water Temperature Debate: Cold vs. Warm

There is no single "right" temperature, but rather a correct sequence. Start with cold water for honey, then use warm water for wax. Using hot water immediately can sometimes make honey stickier before it dissolves.

The Detergent Dilemma: To Use Soap or Not

It is strongly recommended to avoid soap and detergents. Any soap residue left behind, no matter how small, can get into your next honey harvest, affecting its taste and purity. Plain water is sufficient.

If you feel you must use a cleaner, ensure it is a food-grade sanitizer specifically approved for honey-processing equipment and that you rinse it with exceptional thoroughness.

Letting the Bees Do the Work

One popular method is to place the extractor outdoors (at a safe distance from your hives) and let your bees "rob" the remaining honey. They will do a remarkably good job of cleaning it out.

The trade-off is that this can incite a robbing frenzy among hives and potentially spread disease if bees from other colonies join in. It's a great first step, but a final water rinse is still recommended.

Using a Pressure Washer

A pressure washer can be very effective, but it comes with risks. The high pressure can damage delicate parts, bearings, or the motor on an electric extractor. If you use one, use a low-pressure setting and be extremely careful around sensitive components. Some beekeepers take their extractor to a self-serve car wash for this purpose.

Final Recommendations for Your Goal

After cleaning, ensure your extractor is bone-dry. Cover it with a tarp or its original cover and store it in a dry, pest-free location like a garage or shed.

- If your primary focus is honey purity: Avoid all soaps and detergents, relying solely on a cold, then warm, water cleaning sequence.

- If your primary focus is efficiency: Allow your bees a day to clean out the majority of the honey before you begin your manual wash with water.

- If your primary focus is long-term equipment care: Prioritize making the extractor completely dry before storage to prevent any possibility of rust or mold.

Properly cleaning and storing your extractor protects your investment and ensures every future harvest is as pure and delicious as the last.

Summary Table:

| Step | Action | Key Detail |

|---|---|---|

| 1 | Scrape Solids | Remove wax/propolis chunks with a hive tool. |

| 2 | Cold Water Rinse | Dissolves honey; prevents it from cooking on. |

| 3 | Warm Water Wash | Softens and removes remaining beeswax. |

| 4 | Dry Thoroughly | Critical to prevent rust and mold during storage. |

HONESTBEE supplies durable, easy-to-clean beekeeping equipment to commercial apiaries and distributors. Protect your honey's purity and your equipment's longevity with our wholesale-focused solutions. Contact our experts today to discuss your apiary's supply needs!

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- HONESTBEE 6 Frame Three Use Electric Honey Extractor for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

People Also Ask

- How long does it take to extract honey with an extractor? Plan Your Harvest for Maximum Efficiency

- What is the purpose of decanting in honey extraction? Achieve a Purer, More Stable Honey Product

- How long does it take to extract honey with an electric extractor? Cut extraction time to minutes.

- What are the advantages of automatic honey extractors? Scale Your Apiary with Unmatched Efficiency

- Can a manual extractor be upgraded to an electric one? Save Labor & Boost Efficiency