To reduce honey moisture effectively, you must increase the honey's surface area while exposing it to dry air. The most common techniques for beekeepers involve placing open containers of honey in a sealed room with a dehumidifier and a fan, while commercial processors may use controlled heat, vacuum chambers, or specialized equipment to accelerate the process.

The core challenge of dehumidifying honey is not just removing water, but doing so without damaging its delicate enzymes and flavor. The goal is to create an environment where moisture is drawn from the honey and removed from the air, a process best achieved by managing air humidity, temperature, and honey surface area.

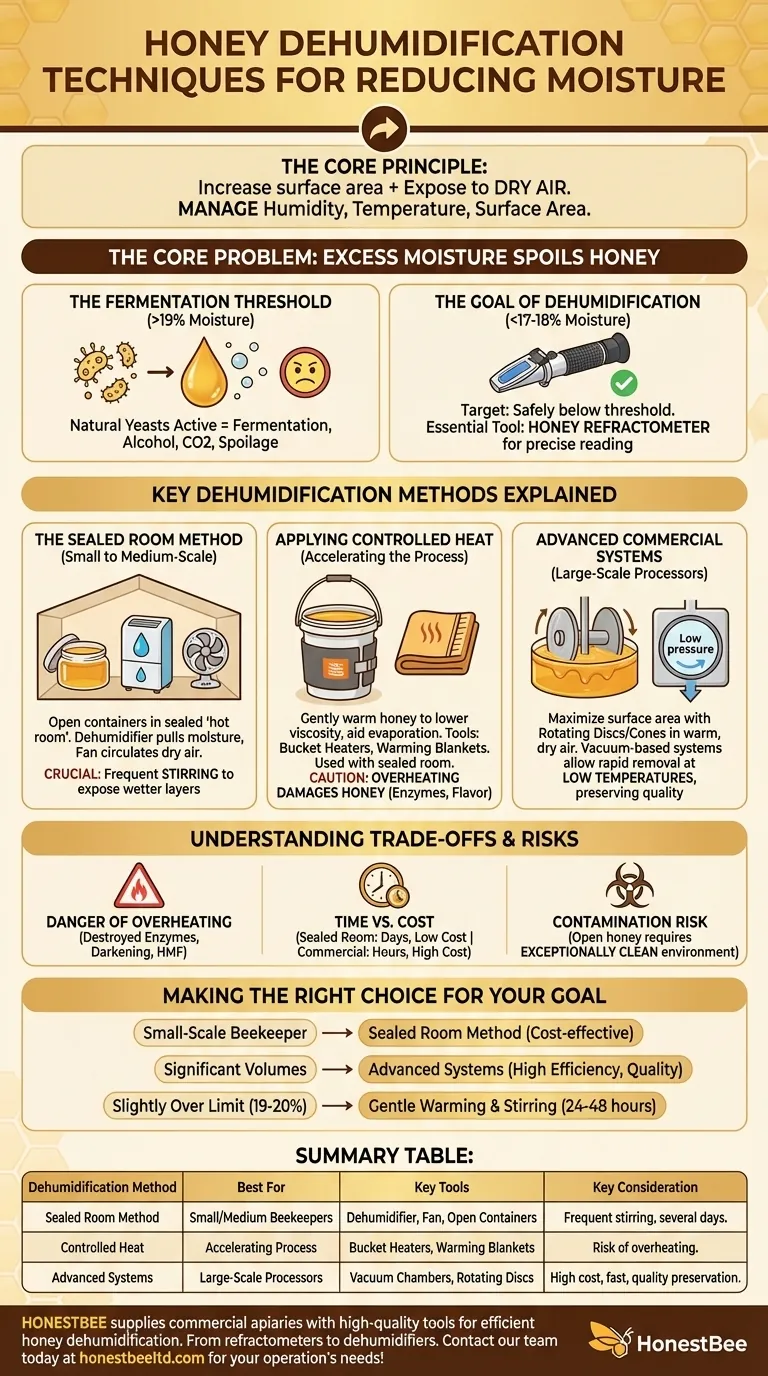

The Core Problem: Why Excess Moisture Spoils Honey

Before diving into techniques, it's critical to understand why moisture content is the single most important factor for honey's shelf stability.

The Fermentation Threshold

Honey contains natural yeasts. When the moisture content rises above approximately 19%, these dormant yeasts can become active and begin to ferment the sugars in the honey.

This fermentation process produces alcohol and carbon dioxide, leading to a sour taste, a frothy appearance, and spoilage. It renders the honey unfit for sale or consumption.

The Goal of Dehumidification

The primary objective is to bring the honey's moisture content safely below the fermentation threshold, typically to a target of 17-18%.

To monitor this process, a honey refractometer is an essential tool. It provides an instant and accurate reading of the moisture percentage, allowing you to know precisely when the honey is stable.

Key Dehumidification Methods Explained

The methods range from simple, small-scale setups to advanced commercial systems. All are based on the same physical principles.

The Sealed Room Method

This is the most accessible technique for small to medium-scale beekeepers. You create a small, sealed "hot room" and place your uncovered honey supers or buckets inside.

A commercial dehumidifier is used to pull moisture out of the air, creating a very dry environment. A fan is added to circulate the dry air across the surface of the honey, accelerating evaporation.

The Importance of Stirring and Surface Area

Water only evaporates from the top layer of the honey. Because honey is so viscous, moisture from the bottom will not easily migrate to the surface.

Stirring the honey in its container several times a day is crucial. This exposes new, wetter layers of honey to the dry air, dramatically speeding up the dehumidification process.

Applying Controlled Heat

Gently warming honey lowers its viscosity, making it flow more easily. This allows moisture to escape more readily.

Tools like bucket heaters or warming blankets can be wrapped around containers. This method is often used in conjunction with the sealed room technique to make the process more efficient.

Advanced Commercial Systems

Large-scale processors require faster, more consistent methods. These often involve equipment that maximizes honey surface area.

This can include rotating discs or cones that are dipped in honey and spun in a current of warm, dry air. Vacuum-based systems are also used to lower the boiling point of water, allowing for rapid moisture removal at very low temperatures, which best preserves the honey's quality.

Understanding the Trade-offs and Risks

Choosing a method requires balancing efficiency, cost, and the potential for damaging the honey.

The Danger of Overheating

This is the most significant risk. Applying too much heat will destroy the delicate enzymes (like diastase and invertase) and volatile flavor compounds that make honey valuable.

Overheating also darkens the honey and can increase its HMF (hydroxymethylfurfural) content, both of which are markers of poor quality or adulteration. Gentle, controlled warming is key.

Time vs. Cost

The sealed room method is inexpensive but can take several days to be effective, depending on the starting moisture level and the room's conditions.

Specialized commercial equipment is a significant capital investment but can reduce moisture content in a matter of hours, increasing throughput and preserving maximum quality.

Contamination Risk

Any time honey is left open to the air, there is a risk of absorbing foreign odors or collecting dust and debris. The dehumidifying room must be exceptionally clean and used only for this purpose.

Making the Right Choice for Your Goal

Select your dehumidification strategy based on the scale of your operation and your quality priorities.

- If you are a small-scale beekeeper: Focus on the sealed room method with a dehumidifier, fan, and frequent stirring, as it is the most cost-effective and reliable solution.

- If you are processing significant volumes: Investigate systems that use controlled, low-temperature heat or vacuum processing to maximize efficiency while preserving honey quality.

- If your honey is only slightly over the limit (e.g., 19-20%): Gentle warming with a bucket heater combined with stirring for 24-48 hours may be all that is required.

Ultimately, managing moisture is about precisely controlling the environment to create a stable, high-quality product that stands the test of time.

Summary Table:

| Dehumidification Method | Best For | Key Tools | Key Consideration |

|---|---|---|---|

| Sealed Room Method | Small to Medium-Scale Beekeepers | Dehumidifier, Fan, Open Containers | Requires frequent stirring; can take several days. |

| Controlled Heat | Accelerating the Process | Bucket Heaters, Warming Blankets | Risk of overheating and damaging honey quality. |

| Advanced Commercial Systems | Large-Scale Processors | Vacuum Chambers, Rotating Discs | High cost but fast, efficient, and preserves quality. |

Need reliable equipment to dehumidify your honey efficiently? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the high-quality tools essential for this critical process. From durable honey refractometers for precise moisture testing to robust dehumidifiers and warming solutions, we provide the wholesale supplies you need to protect your honey's quality and shelf life. Contact our team today to discuss your operation's needs and get a quote.

Visual Guide

Related Products

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

People Also Ask

- What are some tips for preventing excess moisture in honey during harvesting? Essential Steps for a Stable Harvest

- What is the importance of controlling moisture content in honey processing? Prevent Fermentation & Maximize Quality

- What removes moisture from the air? The Two Most Effective Methods for a Dry, Healthy Space

- What is the primary function of professional dehumidification equipment in honey processing? Stability & Quality

- What are the drawbacks of the conventional honey drying method? Avoid Quality Loss and HMF Spikes

- Why is it necessary to maintain honey water content below 20%? Prevent Fermentation & Ensure Professional Quality

- What is the issue with high moisture content in honey? Prevent Fermentation & Protect Your Honey's Value

- What are the key features of the honey dryer? Essential Guide to Advanced Moisture Reduction Technology