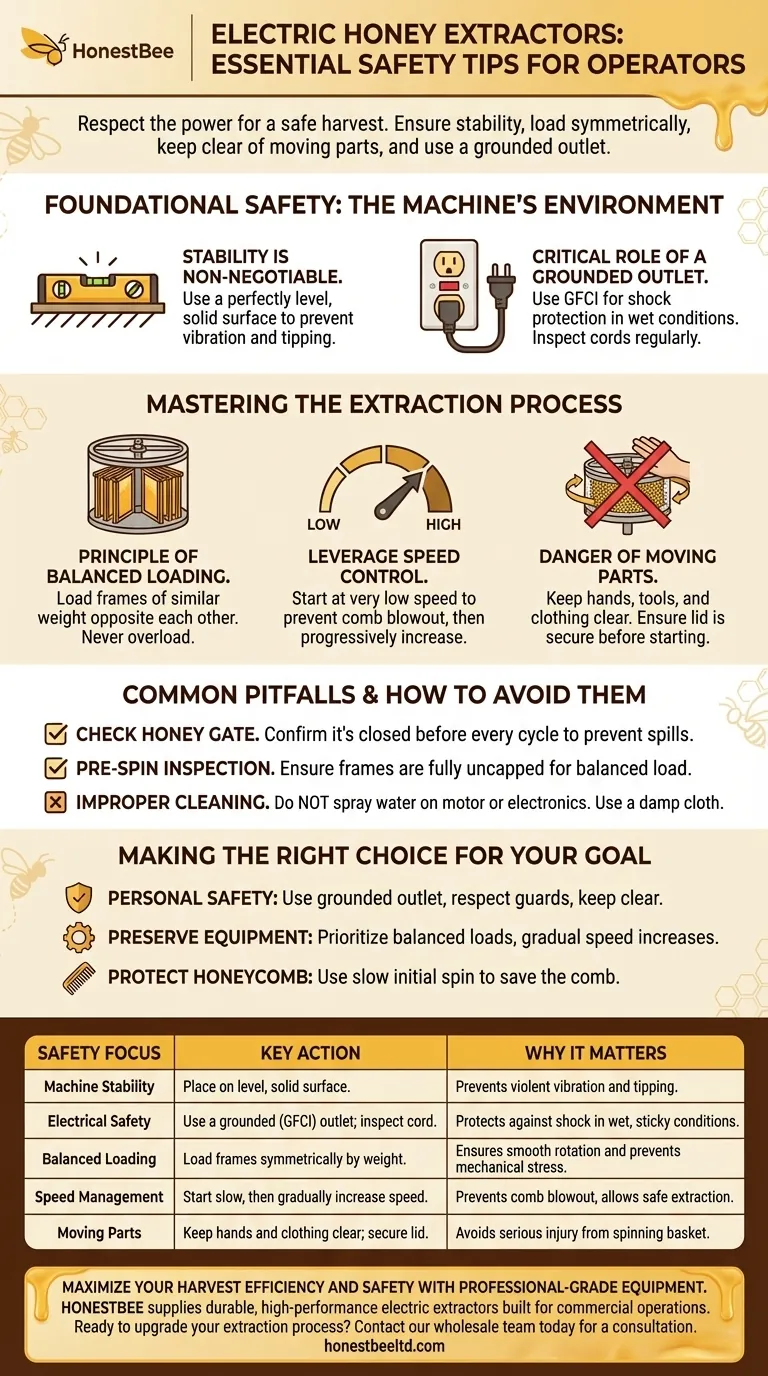

Operating an electric honey extractor safely is a matter of respecting its mechanical and electrical power. The fundamental rules are to ensure the machine is on a stable, level surface, to load frames symmetrically to maintain balance, to keep hands and clothing far from moving parts, and to use a properly grounded electrical outlet to prevent shock.

An electric extractor's speed is its greatest advantage, but an unbalanced, high-speed rotation is its greatest hazard. True safety, therefore, comes not from a simple checklist, but from understanding how to manage the powerful forces of a spinning load.

Foundational Safety: The Machine's Environment

Your first priority is securing the extractor itself. The immense forces generated during operation can turn a small oversight in setup into a major failure.

Why Stability is Non-Negotiable

An extractor spinning dozens or hundreds of pounds of honey and wax at high RPMs creates tremendous rotational force. If the machine is not on a perfectly level and solid floor, it will begin to vibrate.

This vibration can quickly escalate, causing the extractor to "walk" across the floor or even tip over, resulting in catastrophic damage to the equipment and a significant safety hazard.

The Critical Role of a Grounded Outlet

Honey extraction can be a sticky, wet process. These conditions increase the risk of electrical shock if there is a fault in the machinery's wiring.

A grounded outlet (GFCI) is essential. It provides a safe path for stray electricity to travel, tripping a circuit breaker instead of passing through your body. Always inspect the cord and plug for any signs of wear or damage before use.

Mastering the Extraction Process

Safe operation is an active process that requires your attention, especially when starting a new load. The primary cause of problems is almost always an imbalanced load.

The Principle of Balanced Loading

Think of your extractor like a washing machine during its spin cycle. A single heavy, wet towel will cause the entire machine to shake violently. The same principle applies here.

You must load the frames symmetrically. Place frames of similar weight and honey content directly opposite each other in the basket. This creates a balanced center of gravity, allowing for a smooth, vibration-free spin. Never overload the extractor beyond its rated capacity.

Leveraging Speed Control for Safety

The speed controller is your most important safety and operational tool. Starting the extractor at full speed with full, heavy frames is a recipe for disaster.

Begin every cycle at a very low speed. This allows some of an uncapped frame's honey to be thrown from the outer cells, lightening the load. After a few minutes, you can progressively increase the speed to finish the extraction. This gradual approach prevents the weight of the honey from blowing out and destroying the delicate wax comb.

The Danger of Moving Parts

The extractor's spinning basket has significant mass and torque. It will not stop instantly and can easily cause serious injury.

Keep all hands, tools, and loose clothing far away from the machine while it is operating. Ensure the lid is securely fastened, as it acts as a crucial safety guard. Never try to adjust a frame or reach into the basket while it is still in motion.

Common Pitfalls and How to Avoid Them

The efficiency of an electric extractor can lead to haste and overconfidence. Understanding these common mistakes is key to developing safe habits.

Forgetting to Check the Honey Gate

It is a common and frustrating mistake to run an entire cycle only to realize the honey gate at the bottom of the tank was left open, spilling your harvest all over the floor. Make it a habit to check that the gate is closed before every single run.

Neglecting Pre-Spin Frame Inspection

Before loading frames, ensure they are fully uncapped. Any significant sections of capped cells on one side of a frame can contribute to an unbalanced load, as the honey cannot be extracted from that area.

Improper Cleaning Practices

When cleaning up, never spray water directly onto the motor, speed controller, or other electrical components. Use a damp cloth to wipe down these areas. Water in the electronics is a primary cause of electrical faults and equipment failure.

Making the Right Choice for Your Goal

Your approach to safety should align with your primary objective for the harvest.

- If your primary focus is personal safety: Treat the extractor like any powerful workshop tool by using a grounded outlet, respecting all safety guards, and never placing hands or tools inside while it is in motion.

- If your primary focus is preserving your equipment: Always prioritize balanced loads and gradual speed increases to prevent violent shaking and mechanical stress on the basket, motor, and bearings.

- If your primary focus is protecting your honeycomb: Use a slow initial spin to extract from the first side without breaking the comb, allowing for a faster, more complete extraction on the second side.

By mastering these principles, you transform a powerful machine from a potential hazard into a safe and efficient partner in your harvest.

Summary Table:

| Safety Focus | Key Action | Why It Matters |

|---|---|---|

| Machine Stability | Place on a level, solid surface. | Prevents violent vibration and tipping during high-speed spin. |

| Electrical Safety | Use a grounded (GFCI) outlet; inspect cord. | Protects against shock in wet, sticky conditions. |

| Balanced Loading | Load frames symmetrically by weight. | Ensures smooth rotation and prevents mechanical stress. |

| Speed Management | Start slow, then gradually increase speed. | Prevents comb blowout and allows for safe, efficient extraction. |

| Moving Parts | Keep hands and clothing clear; secure lid. | Avoids serious injury from the powerful spinning basket. |

Maximize Your Harvest Efficiency and Safety with Professional-Grade Equipment

For commercial apiaries and beekeeping equipment distributors, operational safety and equipment reliability are paramount to profitability. A safe harvest protects your team, preserves your valuable honeycomb, and ensures your extractor lasts for seasons to come.

HONESTBEE supplies the durable, high-performance electric honey extractors and beekeeping supplies built for the demands of commercial-scale operations. We help you minimize downtime and maximize yield.

Ready to upgrade your extraction process with equipment designed for safety and efficiency?

Contact our wholesale team today for a consultation and discover how our solutions can support your business goals.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

People Also Ask

- What are the main types of honey extractor machines? A Guide for Beekeepers

- Is the honey extractor better than the honey press? Choose the Right Tool for Your Apiary's Success

- What are the main types of honey extractors? Choose the Right Model for Your Apiary

- What are the characteristics of motors used in honey extractors? Ensure Efficient, Damage-Free Honey Harvesting

- Should I get a manual or electric honey extractor? Choose the right extractor for your beekeeping scale.