The core benefits of a honey filtering machine are the significant improvements it brings to product quality, operational efficiency, and marketability. By systematically removing impurities like wax particles and debris, these machines produce honey that is clearer, has a smoother texture, and boasts a longer shelf life, making it more appealing to a broader market.

A honey filtering machine is more than a cleaning tool; it is a strategic investment in consistency. It standardizes a naturally variable product, ensuring every jar meets the same high standard of purity and appearance required for commercial success.

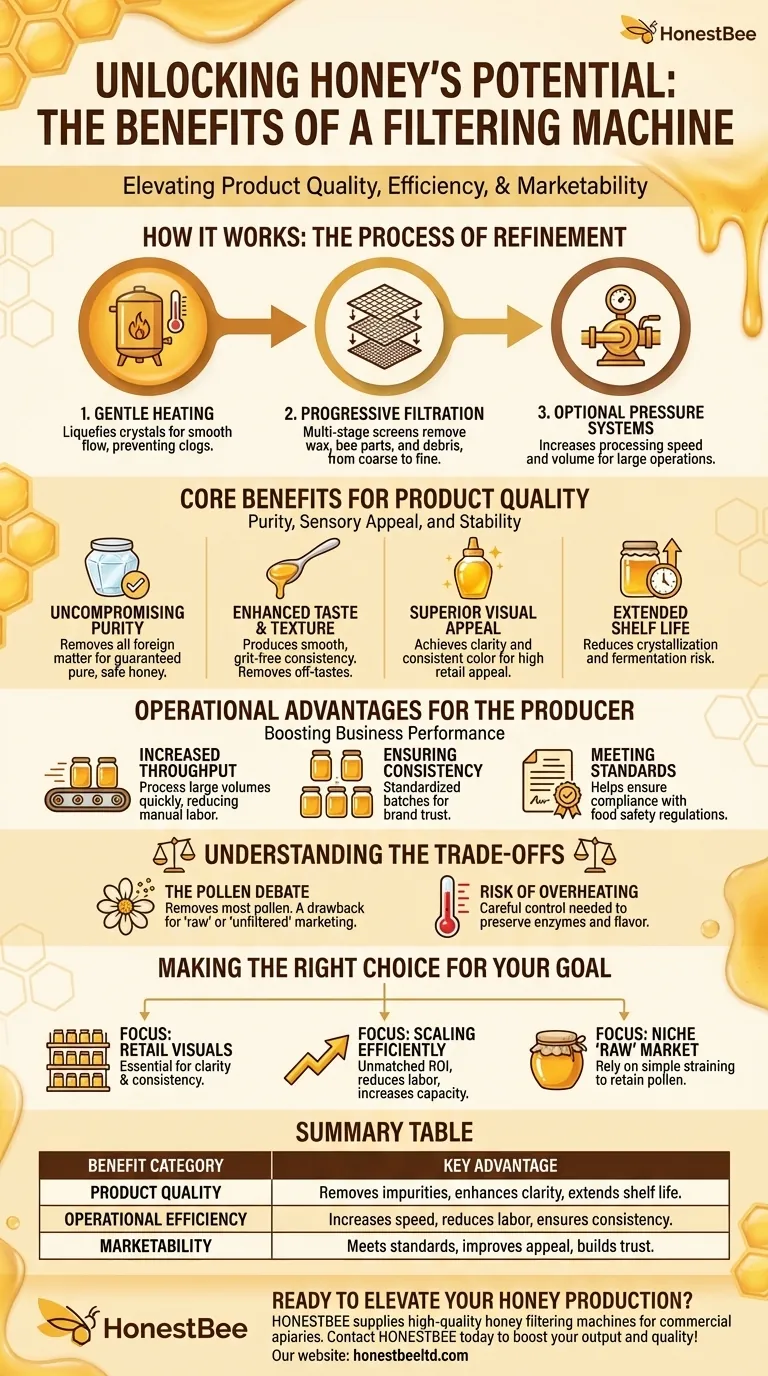

How a Honey Filtering Machine Works

To appreciate the benefits, it's essential to understand the process. The machine refines raw honey through a controlled, multi-stage system designed for purity and efficiency.

The Role of Gentle Heating

Most systems begin by gently heating the honey in a tank. This is not for cooking, but to liquefy any naturally occurring sugar crystals.

This step ensures the honey flows smoothly and can pass through the filters without clogging, which is critical for an efficient process.

Progressive Filtration Stages

The liquified honey is then passed through a series of progressively finer mesh screens or filters.

Early stages catch larger debris like wax bits and bee parts, while later, finer stages remove smaller particulates. This staged approach prevents the finest filters from clogging too quickly.

Optional Pressure Systems

Some advanced machines use pressure or pump systems to move the honey through the filters. This significantly increases the speed and volume of honey that can be processed in a given time, a key feature for larger-scale operations.

Core Benefits for Product Quality

The primary goal of filtration is to elevate the final product. The machine achieves this by impacting purity, sensory characteristics, and stability.

Uncompromising Purity

The most direct benefit is the removal of all foreign matter. This includes wax, propolis, bee parts, splinters from the hive, and other environmental debris.

This guarantees a final product that is pure honey, free from undesirable and inedible contaminants.

Enhanced Taste and Texture

By removing particulates, the machine produces honey with an exceptionally smooth texture. This "grit-free" consistency is highly preferred by most consumers.

While filtration doesn't fundamentally change the honey's flavor profile, it removes any "off-tastes" that can be introduced by impurities.

Superior Visual Appeal

Unfiltered honey is often cloudy or contains visible specks. A filtering machine creates a product with brilliant clarity and a consistent, appealing color.

This visual perfection is a major factor in consumer purchasing decisions in a retail environment.

Extended Shelf Life

Impurities, especially fine particles, can act as nucleation sites that accelerate crystallization. Removing them helps the honey remain liquid for much longer.

Furthermore, removing contaminants reduces the risk of fermentation, ensuring the product remains stable and safe for consumption.

Operational Advantages for the Producer

Beyond the honey itself, a filtering machine provides significant business advantages, particularly as an operation grows.

Increased Throughput and Efficiency

For any commercial-scale beekeeper, manual filtering is a significant bottleneck. A machine can process a large volume of honey quickly and with minimal supervision.

This makes the entire extraction and bottling process more time-efficient and cost-effective, freeing up labor for other critical tasks.

Ensuring Consistency Across Batches

A machine provides a repeatable, standardized process. This ensures that every batch of honey has the same level of clarity and texture, which is crucial for building brand trust and reputation.

Meeting Regulatory Standards

Many food safety and quality standards require honey to be free of foreign materials. Using a certified filtering process helps ensure your product is compliant and ready for commercial sale.

Understanding the Trade-offs

While highly beneficial, mechanical filtration is a specific process with implications that may not suit every producer's goals.

The Pollen Debate: Purity vs. "Raw"

The fine filters that remove debris also remove most pollen grains. For producers marketing their product as "raw" or "unfiltered," this is a significant drawback.

Some consumers specifically seek out honey with its natural pollen content for its perceived health benefits and local character.

The Risk of Overheating

The heating stage is critical but must be carefully controlled. If the honey is overheated, its delicate enzymes can be denatured and its complex flavors damaged.

Quality machines use gentle, well-regulated heating systems to mitigate this risk, but it remains a crucial operational consideration.

Making the Right Choice for Your Goal

Deciding whether to invest in a filtering machine depends entirely on the type of product you aim to create and the market you serve.

- If your primary focus is producing crystal-clear liquid honey for retail shelves: A filtering machine is an essential tool for achieving the visual appeal and consistency consumers expect.

- If your primary focus is scaling your operation efficiently: The machine offers an unmatched return on investment by drastically reducing manual labor and increasing your processing capacity.

- If your primary focus is selling "raw" and "unfiltered" honey to niche markets: You should likely rely on simple straining to retain pollen, as fine machine filtration works against this specific product goal.

Ultimately, integrating a filtering machine is a strategic decision that aligns your production method with your specific product goals and market position.

Summary Table:

| Benefit Category | Key Advantage |

|---|---|

| Product Quality | Removes impurities (wax, debris), enhances clarity, extends shelf life. |

| Operational Efficiency | Increases processing speed, reduces manual labor, ensures batch consistency. |

| Marketability | Meets retail standards, improves visual appeal, builds brand trust. |

Ready to elevate your honey production? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-quality honey filtering machines and other essential supplies through our wholesale-focused operations. Our equipment is designed to deliver the purity, efficiency, and consistency your business needs to succeed. Contact HONESTBEE today to discuss your specific requirements and boost your operation's output and quality!

Visual Guide

Related Products

- Stainless Steel Triangle Support Honey Strainer and Filters

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Stainless Steel Manual 8 Frame Radial Honey Extractor Machine for Beehives

- Professional 4 Frame Self Reversing Electric Honey Extractor for Beekeeping

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

People Also Ask

- What specific role do Honey Purification and Filtration Systems play? Elevate Your Exports for Global Markets

- What is the function of precision filtration devices in the preparation of propolis ethanol extracts?

- What roles do specialized brewing and filtration systems play in mead production? Enhance Honey Value and Purity

- What are the primary functions of industrial honey filtration and purification systems compared to traditional honey processing?

- Why is the use of high-density filter cloth necessary during the processing of stingless bee honey? Ensure Pure Quality

- Why is the honey filtering process essential? Elevate Your Harvest to Premium Commercial Standards

- Why is high-precision filtering and clarification equipment essential for honey? Meet Export Standards & Quality.

- How does honey filtration equipment impact honey quality? Enhance Clarity and Market Value for Premium Sales