At its core, a beeswax foundation machine provides the beekeeper with unparalleled control over a critical component of the hive. The primary benefits are the ability to produce perfectly uniform, high-quality foundation sheets from your own wax, which encourages faster and healthier comb building by the bees and leads to more efficient honey production.

The decision to use a beeswax foundation machine is not just about manufacturing a product. It is about taking ownership of your hive's starting point, ensuring the wax is pure, the cell structure is perfect, and the foundation is something your bees will readily accept and build upon.

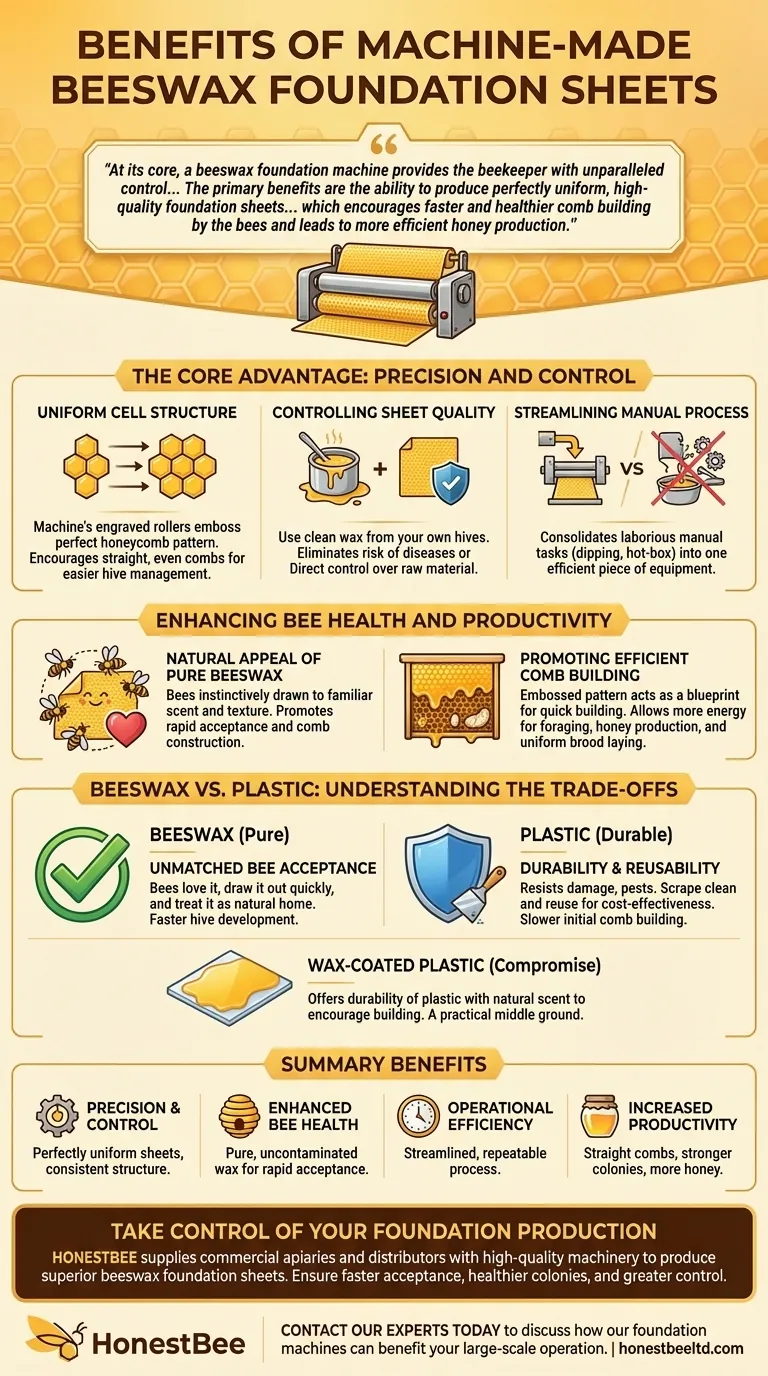

The Core Advantage: Precision and Control

Using a machine transforms foundation-making from a difficult craft into a precise, repeatable process. This control is the most significant advantage over purchasing commercial foundation or attempting to make it by hand.

Achieving Uniform Cell Structure

A foundation machine uses two engraved rollers that emboss a perfect honeycomb pattern onto a sheet of wax. This creates a uniform base with consistently sized cells, which is a critical guide for the bees.

This uniformity encourages bees to build straight, even combs, making hive inspections and honey extraction far easier and less disruptive to the colony.

Controlling Sheet Quality

By making your own foundation, you control the thickness and purity of the sheets. You can use clean wax from your own hives, eliminating the risk of introducing diseases or contaminants that might be present in commercially sourced wax.

This direct control over the raw material is a key factor in maintaining colony health.

Streamlining a Difficult Manual Process

Without a machine, creating foundation is a laborious process requiring multiple vats for melting and dipping wax, custom-made dipping boards, and a hot-box. It is difficult to achieve consistency with this method.

The machine consolidates this into a single, efficient piece of equipment designed for one purpose: producing perfect foundation sheets with minimal effort.

Enhancing Bee Health and Productivity

The ultimate goal of managing foundation is to create an environment where the colony can thrive. A machine-made beeswax foundation directly supports this.

The Natural Appeal of Pure Beeswax

Beeswax foundation is a natural material made from the bees' own product. It has a familiar scent and texture that bees are instinctively drawn to, promoting rapid acceptance and comb construction.

Alternatives like plain plastic can be jarring for bees, often resulting in slower adoption. Even plastic foundations are improved by a coating of beeswax, which underscores the bees' inherent preference for wax.

Promoting Efficient Comb Building

The embossed cell pattern on the foundation acts as a blueprint for the bees. This guidance helps them build out the comb quickly and efficiently, allowing them to spend less energy on construction and more on foraging and honey production.

Straight combs also ensure the queen has optimal, uniform cells for laying eggs, contributing to a strong and healthy brood pattern.

Understanding the Trade-offs: Beeswax vs. Plastic

While machine-made beeswax foundation offers clear benefits for bee acceptance, it's important to understand how it compares to the primary alternative: plastic foundation.

The Case for Beeswax: Unmatched Bee Acceptance

The single greatest advantage of beeswax is that bees love it. They take to it quickly, draw it out evenly, and treat it as a natural part of their home. This leads to faster hive development and productivity.

The Case for Plastic: Durability and Reusability

Plastic foundation is exceptionally durable. It resists damage from handling, hive tools, and pests like wax moths or mice. It can also be scraped clean and reused for many seasons, which can make it more cost-effective over the long term.

The Compromise: Wax-Coated Plastic

Some beekeepers use plastic foundation that has been coated with a layer of beeswax. This attempts to offer the durability of plastic while adding the natural scent and texture that encourages bees to build. However, it is still a compromise compared to the full acceptance of pure beeswax.

Making the Right Choice for Your Apiary

Your decision should be based on your specific goals as a beekeeper, balancing bee preference, operational efficiency, and cost.

- If your primary focus is maximum bee acceptance and purity: Producing your own foundation with a beeswax machine using your own wax is the superior choice.

- If your primary focus is durability and pest resistance: Plastic foundation is a highly resilient and reusable option, though it may slow initial comb building.

- If your primary focus is a balance of durability and bee acceptance: Using wax-coated plastic foundation provides a practical middle ground for many operations.

Ultimately, taking control of your foundation gives you direct influence over the health, efficiency, and productivity of your colonies.

Summary Table:

| Benefit | Key Advantage |

|---|---|

| Precision & Control | Produces perfectly uniform sheets with consistent cell structure. |

| Enhanced Bee Health | Uses pure, uncontaminated wax for rapid acceptance and comb building. |

| Operational Efficiency | Streamlines a difficult manual process into a repeatable, efficient operation. |

| Increased Productivity | Encourages straight comb building, leading to stronger colonies and more honey. |

Ready to take control of your foundation production and boost your apiary's health and efficiency?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the high-quality machinery needed to produce superior beeswax foundation sheets. By producing your own pure wax foundation, you ensure faster bee acceptance, healthier colonies, and greater operational control.

Contact our experts today to discuss how our foundation machines can benefit your large-scale operation.

Visual Guide

Related Products

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

People Also Ask

- What are the castings of the beeswax foundation machine made of? Precision Engineering for Efficient Beekeeping

- How do beeswax foundation molds facilitate the construction of standardized honeycombs? Optimize Your Apiary Efficiency

- What are the sequential stages of operation for a beeswax flatting and embossing machine? Master High-Quality Wax Sheets

- What are the portability features of the manual honeycomb embossing machine? Achieve On-Site Foundation Control

- What is the primary function of a wax printer in beekeeping? Optimize Hive Energy and Boost Honey Yields

- What are the characteristics of the beeswax foundation sheets produced by this type of machine? | HONESTBEE Insights

- Why are specific wax foundation molds used to downsize brood cells? Master Mechanical Pest Inhibition

- What is the proper method for heating beeswax to make sheets? Master the Double Boiler & Temp Control for Perfect Results.