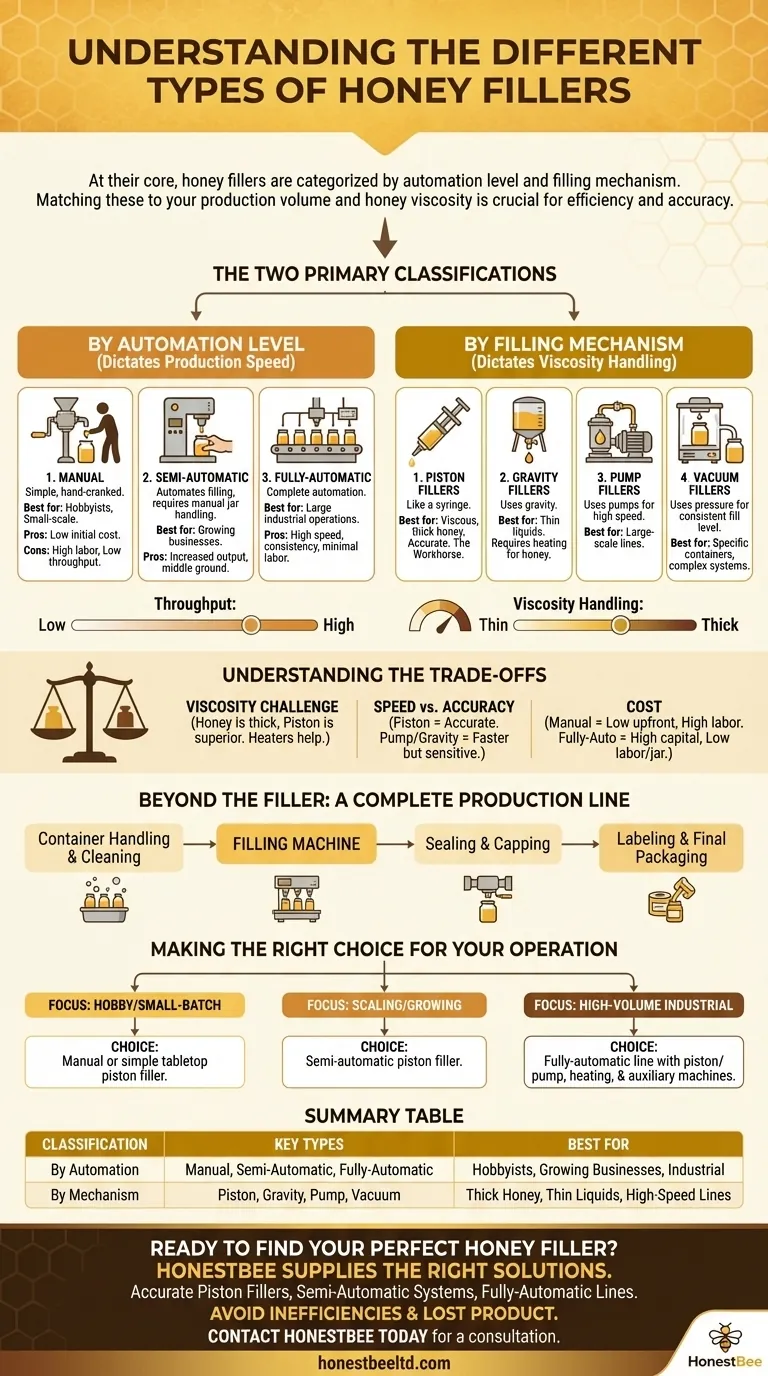

At their core, honey fillers are categorized in two primary ways: by their level of automation (manual, semi-automatic, or fully-automatic) and by their filling mechanism (piston, gravity, vacuum, or pump). The level of automation dictates production speed, while the mechanism determines how well the machine handles honey's unique thickness.

The most critical decision is not simply choosing a "type" of filler, but matching the right filling mechanism to your honey's viscosity and the right automation level to your production volume. Get this alignment wrong, and you face inefficiency, inaccuracy, and lost product.

The Two Primary Ways to Classify Honey Fillers

Understanding these two classification methods is the key to navigating your options. One defines the operational scale, and the other defines the physical method of moving the honey.

Classification by Automation Level

This determines the amount of human labor required and directly correlates to your production output, or throughput.

-

Manual Fillers Manual fillers are simple, often hand-cranked or lever-operated devices. They are best suited for hobbyists, small-scale beekeepers, or farmers' market vendors.

They offer the lowest initial cost but require the most labor per container, making them unsuitable for large volumes.

-

Semi-Automatic Fillers These machines automate the filling process itself but require an operator to manually place jars under the nozzle and move them to the next station (like capping). They represent a middle ground for growing businesses that need to increase output beyond manual capabilities.

-

Fully-Automatic Fillers In a fully-automatic system, every step from placing the empty container to filling, capping, and labeling is handled by machinery with minimal human intervention. These are designed for large industrial operations where speed and consistency are paramount.

Classification by Filling Mechanism

This describes the technology used to move the honey from a bulk tank into the individual container. This choice is dictated almost entirely by the product's viscosity (thickness).

-

Piston Fillers: The Workhorse for Honey Piston fillers are the most common and effective choice for viscous products like honey. They operate like a large syringe, pulling a precise, pre-set volume of honey into a cylinder and then pushing it out into the container.

This method is extremely accurate and reliable, handling thick, unheated honey better than other mechanisms.

-

Gravity Fillers: For Thinner Liquids Gravity fillers hold the product in a tank above the filling nozzles. A valve opens for a set amount of time, allowing gravity to fill the container below.

This method is simple and cost-effective but is best suited for low-viscosity (thin) liquids. For honey, it typically requires a heating system to reduce viscosity, which allows the honey to flow more freely.

-

Pump and Vacuum Fillers: Specialized Applications Pump fillers use a pump to move product, offering high speeds for large-scale lines. Vacuum fillers use pressure to ensure a consistent fill level, which is useful for certain container types.

These are generally more complex and are typically integrated into fully-automatic systems for specific production requirements.

Understanding the Trade-offs

Choosing a filler involves balancing cost, speed, and the physical properties of your honey. A cheap solution that doesn't work is more expensive than the right solution.

The Viscosity Challenge

Honey's thickness is its biggest filling challenge. Raw, unfiltered, or crystallized honey is extremely viscous and will not work well with a gravity filler unless heated. Piston fillers are mechanically superior for pushing this thick product accurately.

Many advanced systems incorporate heaters or heated hoppers to gently warm the honey, reducing its viscosity and making it easier to pump and fill regardless of the mechanism.

Speed vs. Accuracy

Piston fillers offer excellent volumetric accuracy, ensuring each jar has the same weight of product. Pump and gravity systems can be faster, but their accuracy can be more sensitive to changes in honey temperature and viscosity.

Initial Investment vs. Operational Cost

A manual filler has a very low upfront cost but a high labor cost per jar. A fully-automatic line is a major capital investment but dramatically reduces the labor cost per jar, making it more profitable at high volumes. Semi-automatic machines offer a balance between these two extremes.

Beyond the Filler: Building a Complete Production Line

A filling machine is just one component of a larger packaging process. For semi-automatic and fully-automatic operations, you will need to consider auxiliary equipment.

Container Handling and Cleaning

For automated lines, a bottle unscrambler orients and feeds jars onto the conveyor. A bottle washing machine ensures containers are clean before filling.

Sealing and Capping

After filling, a capping machine automatically applies and tightens the lids. This is a critical step for ensuring a proper seal and product shelf life.

Labeling and Final Packaging

Finally, an automatic labeling machine applies your brand labels consistently before the jars are packed into cases for shipping.

Making the Right Choice for Your Operation

Filter your options based on your primary business goal.

- If your primary focus is a hobby or small-batch business: A manual or simple tabletop piston filler provides the necessary function without a large capital investment.

- If your primary focus is scaling a growing business: A semi-automatic piston filler is your most logical next step, boosting output while managing costs.

- If your primary focus is high-volume, industrial production: A fully-automatic, integrated line with a piston or pump filler, heating, and auxiliary machines is necessary to achieve efficiency and profitability.

Ultimately, selecting the right honey filler is about investing in the proper tool that allows your operation to function efficiently at its current scale and grow into the next.

Summary Table:

| Classification | Key Types | Best For |

|---|---|---|

| By Automation | Manual, Semi-Automatic, Fully-Automatic | Hobbyists, Growing Businesses, Industrial Production |

| By Mechanism | Piston, Gravity, Pump, Vacuum | Thick Honey, Thin Liquids, High-Speed Lines |

Ready to Find Your Perfect Honey Filler?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the right honey filling solutions to scale their operations efficiently. Whether you're upgrading from manual filling or building a high-volume industrial line, our expertise ensures you invest in equipment that matches your honey's viscosity and production goals.

We help you avoid costly inefficiencies and lost product by providing:

- Accurate Piston Fillers for thick, unheated honey.

- Semi-Automatic Systems to boost your output.

- Fully-Automatic Lines with integrated capping and labeling.

Contact HONESTBEE today for a personalized consultation and wholesale pricing on beekeeping supplies and equipment.

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Manual Honey Filling Machine Bottling Machine for Honey

People Also Ask

- What is the value of honey filling and packaging machinery? Accelerate Commercial Scalability and Global Market Access

- How does the implementation of automated honey-filling machines address the challenge of rising production costs? Achieve Scalability and Precision

- What are the benefits of using automated honey-filling machinery? Boost Efficiency and Value for Commercial Apiaries

- What benefits do industrial-grade filling machines provide? Secure Honey Quality and Hygiene with Precision Automation

- What are the advantages of using automated honey filling equipment? Scaling Your Commercial Honey Production