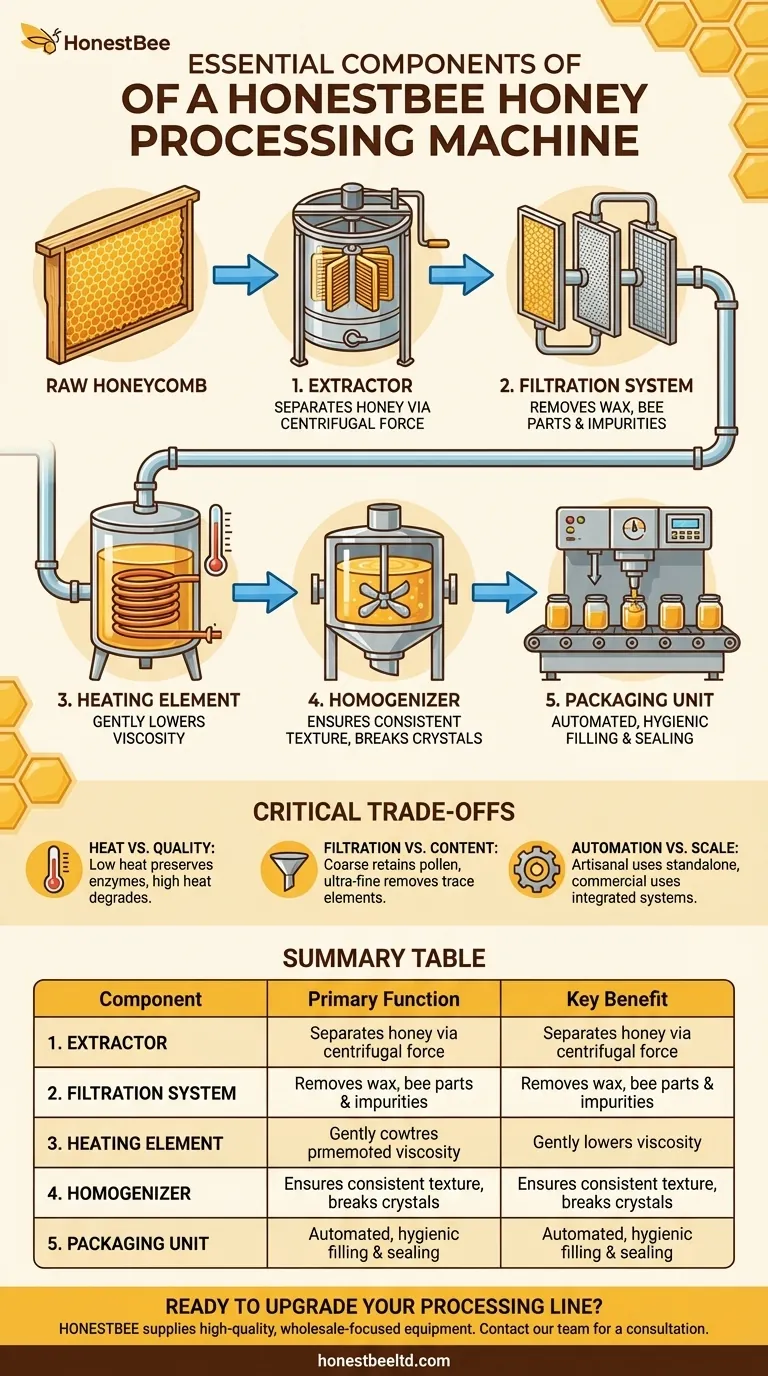

At its core, a honey processing machine is a system of five essential components. These are the extractor, which separates honey from the comb; a filtration system to remove impurities; a gentle heating element to improve honey's fluidity; a homogenizer for consistent texture; and an automated packaging unit to prepare the final product for distribution.

The primary goal of a honey processing machine is to create a clean, consistent, and shelf-stable product. Each component plays a specific role in a sequential process that transforms raw honey from the hive into a marketable good while preserving its quality.

The Journey from Comb to Jar: A Component-by-Component Breakdown

Understanding how raw honey becomes the final product requires looking at the function of each part of the machine. The process is a logical flow from extraction to final packaging.

The Extractor: The First Step

The journey begins with the extractor. This device uses centrifugal force to spin the honeycombs at high speed.

This action effectively pulls the honey out of the wax cells without destroying the comb, which can often be returned to the hive.

The Filtration System: Ensuring Purity

Once extracted, the raw honey contains various impurities like wax particles, bee parts, and other hive debris.

The filtration system is designed to remove these solids. It typically involves a multi-stage process, starting with coarse filtration to catch larger debris and moving to fine filtration for smaller particles, resulting in a clean, clear liquid.

The Heating Element: A Delicate Balance

Cold honey is highly viscous and difficult to filter and pump. A heating element, or preheating tank, gently warms the honey.

The key is to raise the temperature just enough to lower its viscosity for easier processing. This step is critical, as excessive heat can destroy the natural enzymes and delicate flavors that define high-quality honey.

The Homogenizer: Creating Consistency

After filtering, the honey is passed through a homogenizer. This component ensures a uniform texture and quality throughout the entire batch.

It works by agitating and sometimes pressurizing the honey to break down any small sugar crystals that may have started to form, which helps prevent or delay future crystallization in the jar.

The Packaging Unit: The Final Stage

The final step is packaging. An automated unit efficiently fills jars or other containers to precise volumes.

This not only speeds up production but also ensures a hygienic transfer from the processing line into the sealed, shelf-ready container.

Understanding the Critical Trade-offs

While these components create an efficient system, their operation involves important decisions that directly impact the final product's quality and character.

Heat vs. Quality

The most significant trade-off is between processing efficiency and honey quality. While warming honey makes it flow easily, overheating will degrade it.

High temperatures can destroy beneficial enzymes and alter the taste profile. The best systems use low-temperature warming over a longer period to preserve the honey's natural integrity.

Filtration Level vs. Natural Content

Aggressive, ultra-fine filtration can produce exceptionally clear honey, but it can also remove beneficial trace elements like pollen.

Many consumers of raw or natural honey value the presence of local pollen. The choice of filtration level depends entirely on the target market and desired product standard.

Automation vs. Scale

The components described are often part of a large, integrated industrial machine. However, they can also exist as separate pieces of equipment.

Small-scale beekeepers may only use a standalone extractor and a simple filter. Large commercial operations, on the other hand, rely on fully automated, end-to-end systems to ensure high productivity and standardized quality.

Making the Right Choice for Your Goal

Selecting the right equipment depends entirely on your production objectives.

- If your primary focus is artisanal or raw honey: Your core components are a quality extractor and a coarse filtration system, minimizing or eliminating heat.

- If your primary focus is large-scale commercial sales: An integrated system with all five components is essential for achieving the consistency, shelf stability, and efficiency required for retail distribution.

- If your primary focus is creating a crystal-clear product: A robust fine filtration system, combined with gentle preheating, will be the most critical part of your operation.

Ultimately, understanding each component's function empowers you to build a process that aligns perfectly with your quality standards and business goals.

Summary Table:

| Component | Primary Function | Key Benefit |

|---|---|---|

| Extractor | Separates honey from comb using centrifugal force | Preserves honeycomb for reuse |

| Filtration System | Removes wax, bee parts, and other impurities | Ensures a clean, clear final product |

| Heating Element | Gently warms honey to reduce viscosity | Enables easier pumping and filtering |

| Homogenizer | Agitates honey to break down sugar crystals | Creates a uniform texture and delays crystallization |

| Packaging Unit | Automatically fills and seals containers | Ensures hygiene, speed, and precise volumes |

Ready to build or upgrade your honey processing line?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the high-quality, wholesale-focused equipment needed for efficient and scalable honey production. Whether you need a single component like an extractor or a fully integrated system, our expertise ensures you get the right machinery to meet your quality standards and business goals.

Contact our team today for a consultation on the best processing solutions for your operation.

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Automatic Single-Dose Snap & Squeeze Honey Sachets Packing Machine

- 10L Stainless Steel Electric Honey Press Machine

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

- Stainless Steel Honey Press Wax Press with Tank

People Also Ask

- How do industrial honey filling machines ensure compliance? Master Quality Control for Global Export

- What is the primary function of industrial filling equipment? Maximize Honey Profitability and Market Access

- What role does honey-filling and processing machinery play in pollination? Maximize Apiary ROI & Economic Stability

- What are the primary benefits of automated honey-filling machines? Scale Your Commercial Apiary Efficiency

- What is the significance of automated honey-filling machines? Scale Your Apiary with Precision and Efficiency