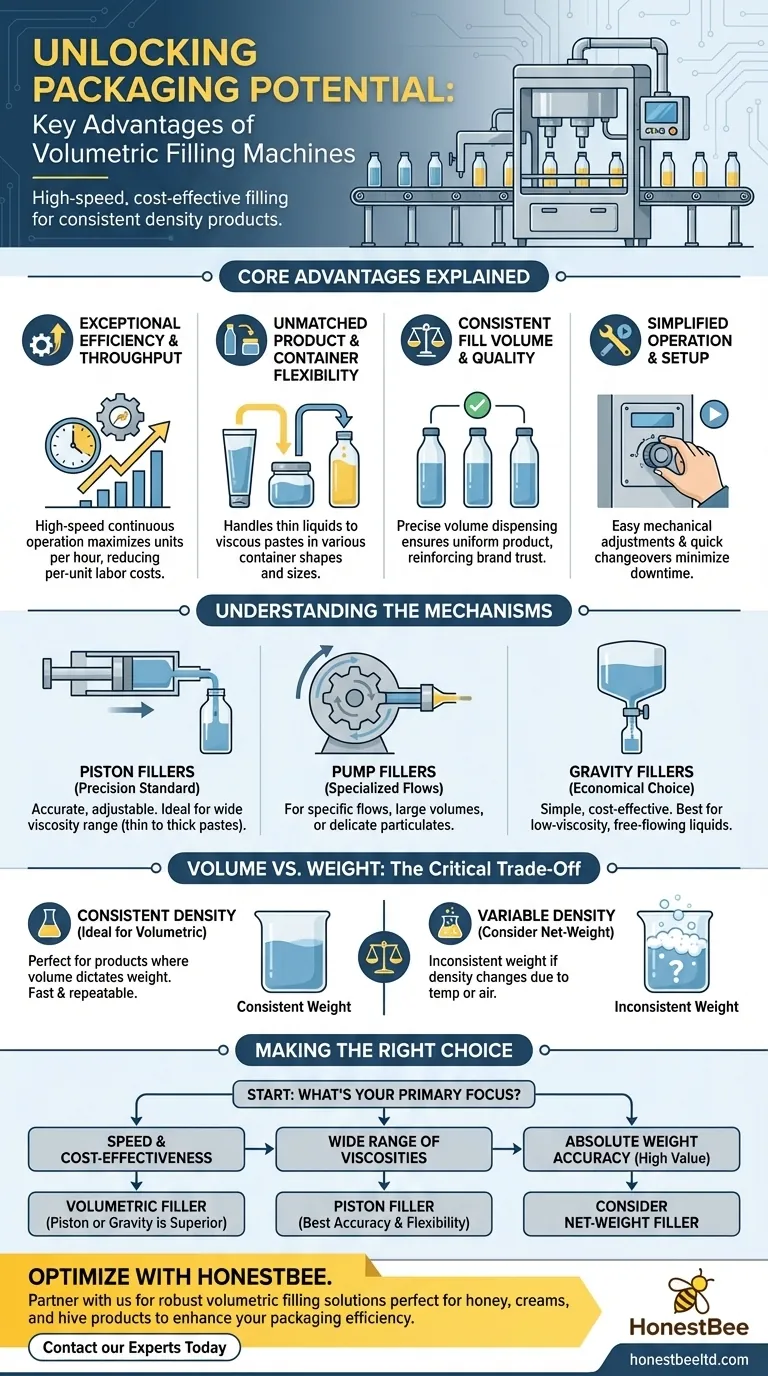

At their core, volumetric filling machines offer four primary advantages: exceptional efficiency, unmatched flexibility, simplified operation, and consistent quality control. They are engineered to dispense a precise volume of product into a container, making them a cornerstone of modern packaging lines by maximizing throughput and minimizing operational complexity.

The central value of a volumetric filler lies in its ability to provide high-speed, cost-effective filling for products with a consistent density. Understanding this principle is the key to deciding if it's the right solution for your operation.

The Core Operational Benefits Explained

The advantages of volumetric fillers translate directly into tangible gains in productivity, cost-savings, and product quality on the production floor.

Efficiency and Throughput

Volumetric systems are built for speed. By dispensing a set volume with each cycle, they can operate continuously at high rates, significantly boosting units produced per hour.

This increased productivity directly reduces per-unit labor costs, making these machines a highly efficient investment for both semi-automatic and fully automated production lines.

Unmatched Product and Container Flexibility

A key strength is their ability to handle a vast array of product types. This includes everything from thin liquids like beverages to viscous products like sauces, creams, and gels.

They are also adaptable to numerous container shapes and sizes, from small tubes and cups for personal care products to larger tins and bottles for food items. This versatility allows one machine to serve multiple product lines.

Consistent Fill Volume and Quality

These machines excel at dispensing the same volume of product time after time. This precision ensures your customers receive a consistent amount in every package, reinforcing brand quality.

Many designs, particularly piston fillers, also inherently minimize the introduction of air during the fill cycle, which is critical for preserving the integrity and shelf life of many food and pharmaceutical products.

Simplified Operation and Setup

Modern volumetric fillers are designed for ease of use. Setup typically involves simple mechanical adjustments to set the fill volume, and changeovers between different products or containers are generally fast.

This straightforward operation reduces the need for highly specialized technical staff and minimizes downtime during production changes.

Understanding the Different Volumetric Mechanisms

Not all volumetric fillers are the same. The technology used to move the product dictates its ideal application.

Piston Fillers: The Precision Standard

Piston fillers are the most common and versatile type. They work by drawing a product into a cylinder and then pushing it out into the container.

The volume dispensed is determined by the cylinder's diameter and the length of the piston's stroke, making it highly accurate and easily adjustable. They are ideal for a huge range of viscosities, from water-thin liquids to thick pastes like toothpaste.

Pump Fillers: For Specialized Flows

Pump fillers use a lobe, gear, or other type of pump to move the product. The fill volume is controlled by the amount of time the pump runs or by counting its rotations.

These are often chosen for specific applications where the product characteristics are well-suited to a particular pump style, such as filling very large volumes or handling products with delicate particulates.

Gravity Fillers: The Economical Choice

Gravity fillers are the simplest design. They hold the product in an overhead tank, and a valve opens for a pre-set amount of time to allow the liquid to flow into the container via gravity.

Because of their simplicity, they are a very cost-effective solution but are generally limited to low-viscosity, free-flowing liquids like water or juice.

The Critical Trade-Off: Volume vs. Weight

The primary limitation of a volumetric filler is also its defining characteristic: it measures volume, not weight.

When Volume is the Deciding Factor

Volumetric filling is the perfect choice when your product has a consistent density. If a liter of your sauce always weighs the same, a volumetric filler will deliver fast, accurate, and repeatable results.

This makes it the standard for the vast majority of liquid and semi-liquid products where minor weight variations between packages are acceptable.

When to Consider a Net-Weight Filler

The system's limitation appears if your product's density changes. This can happen due to temperature fluctuations, trapped air, or batch-to-batch variations.

In these cases, filling a consistent volume will result in an inconsistent final weight. For high-value products sold by weight or in regulated industries, a net-weight filler, which weighs the product as it fills, may be the more appropriate, albeit slower and more expensive, solution.

Making the Right Choice for Your Goal

Selecting the right filler depends entirely on your product, priorities, and operational goals.

- If your primary focus is speed and cost-effectiveness with consistent liquids: A volumetric filler is almost always the superior choice, with piston or gravity systems being excellent starting points.

- If your primary focus is handling a wide range of product types and viscosities: A piston filler provides the best combination of accuracy and flexibility for the investment.

- If your primary focus is absolute final weight accuracy for high-value or inconsistent products: You should evaluate a net-weight filling system as a necessary alternative to ensure compliance and prevent product giveaway.

Choosing the correct filling technology is a foundational decision that impacts your line's efficiency, profitability, and quality for years to come.

Summary Table:

| Advantage | Description | Key Benefit |

|---|---|---|

| Efficiency & Throughput | High-speed, continuous operation | Maximizes units per hour, reduces labor cost |

| Product & Container Flexibility | Handles liquids to pastes; various shapes/sizes | One machine for multiple product lines |

| Consistent Fill Volume | Precise volume dispensing every cycle | Ensures product consistency and brand quality |

| Simplified Operation | Easy setup and quick changeovers | Reduces downtime and need for specialized staff |

Ready to Optimize Your Packaging Line? Partner with HONESTBEE.

As a leading wholesale supplier to commercial apiaries and beekeeping equipment distributors, HONESTBEE provides robust volumetric filling solutions perfect for honey, creams, salves, and other hive products. Our equipment delivers the speed and flexibility your high-volume operation needs to increase throughput and maintain consistent quality.

Let us help you select the ideal piston, pump, or gravity filler for your specific products and containers. Contact our experts today for a personalized consultation and discover how our wholesale-focused operations can enhance your packaging efficiency and profitability.

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Manual Honey Filling Machine Bottling Machine for Honey

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

People Also Ask

- What types of products can be filled and packed using sachet filling and packing machines? Versatile Packaging for Liquids, Pastes & Spreads

- What are the benefits of using industrial honey-filling machines? Boost Efficiency and Preserve Bioactive Quality

- What factors should be considered when choosing between semi-automatic and automatic honey filling machines? Optimize Your Honey Production Line

- What role do industrial honey-filling machines play in food safety? Elevate Standards with HONESTBEE Automation

- What are the advantages of using automated honey filling equipment? Scaling Your Commercial Honey Production

- How do industrial honey-filling machines enhance the production value of raw honey? Maximize Your Retail Potential

- What specific industrial challenges do precision honey filling machines address? Optimize Your Packaging Efficiency

- What is the process of filling and sealing honey stick packs? Master Efficient Packaging for Commercial Honey Sales