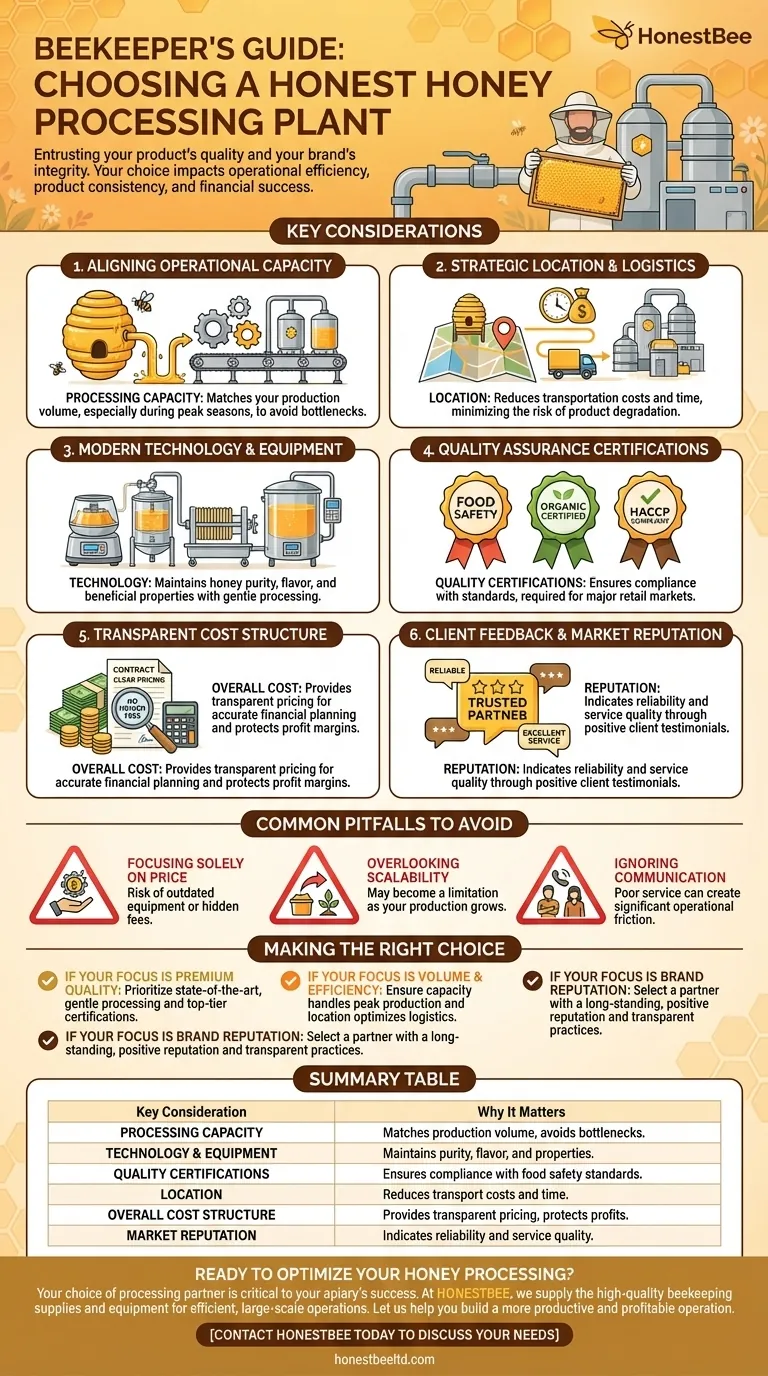

Choosing the right honey processing plant is a critical business decision that extends far beyond simple logistics. The key factors you must evaluate are the plant's processing capacity, the quality of its technology and equipment, its adherence to quality certifications, its market reputation, the complete cost structure, and its physical location.

Selecting a processing partner is not merely outsourcing a task; it is entrusting another company with your product's quality and your brand's integrity. Your choice directly impacts your operational efficiency, product consistency, and financial success.

Aligning on Operational Capacity and Logistics

The first step is to ensure a potential partner can physically and geographically handle your product. A mismatch in these fundamental areas can create immediate and significant bottlenecks for your business.

Matching Your Production Volume

A plant's processing capacity must align with your apiary's output. Ensure they can handle your production volume not just on an average day, but during your peak seasons.

An inability to process your honey in a timely manner can lead to spoilage, storage issues, and lost revenue opportunities.

The Importance of Strategic Location

The plant’s location is crucial for optimizing your supply chain. A geographically favorable partner reduces transportation time and costs.

This efficiency minimizes the risk of product degradation during transit and streamlines your overall distribution network.

Scrutinizing Technology and Quality Assurance

The integrity of your honey is paramount. The equipment and standards upheld by the processing plant will ultimately define the quality of the final product sold under your name.

The Role of Modern Equipment

Evaluate the technology and equipment used in the facility. Look for modern, high-quality extractors, effective straining and filtration systems, and precise pre-heating and moisture-reduction capabilities.

Proper equipment ensures that the honey's purity, flavor, and beneficial properties are maintained throughout the processing journey.

Verifying Quality Certifications

Quality assurance certifications are non-negotiable. They are your proof that the plant complies with established food safety and quality standards.

These certifications provide confidence in the plant's processes and are often a requirement for selling into larger retail markets.

Evaluating the Financial and Reputational Partnership

Beyond the technical specifications, you are entering a business relationship. The financial terms and the partner's reputation in the industry are strong indicators of the experience you can expect.

Understanding the Full Cost

Look beyond the headline price and analyze the overall cost structure. Inquire directly about any potential hidden fees for services like storage, bottling, or specialized filtration.

A transparent cost model is essential for accurate financial planning and avoiding unexpected expenses that erode your profit margins.

Researching Client Feedback and Reputation

A plant's reputation is a powerful indicator of its reliability and service quality. Seek out client testimonials and reviews from other beekeepers.

Consistent positive feedback is a strong sign of a trustworthy and professional partner who values its clients' success.

Common Pitfalls to Avoid

Making a decision based on incomplete information can lead to costly mistakes. Being aware of common oversights is crucial for selecting a long-term strategic partner.

Focusing Solely on Price

Choosing a plant based on the lowest cost alone is a significant risk. Low prices can sometimes indicate outdated equipment, poor quality control, or hidden fees.

Overlooking Scalability

Consider your future growth. A plant that fits your needs today may become a limitation if they cannot scale their services as your production volume increases.

Ignoring Communication and Service

A processing plant is a service provider. Poor communication or inflexible service can create significant operational friction, even if the technical capabilities are excellent.

Making the Right Choice for Your Operation

Your final decision should be a balanced assessment of all these factors, weighted according to your specific business priorities.

- If your primary focus is premium quality: Prioritize a plant with state-of-the-art, gentle processing technology and top-tier food safety certifications.

- If your primary focus is volume and efficiency: Ensure the plant's capacity can handle your peak production and that its location optimizes your supply chain logistics.

- If your primary focus is brand reputation: Select a partner with a long-standing, positive reputation and transparent practices that align with your own brand values.

A well-chosen processing partner acts as a seamless extension of your own commitment to quality.

Summary Table:

| Key Consideration | Why It Matters |

|---|---|

| Processing Capacity | Matches your production volume, especially during peak seasons, to avoid bottlenecks. |

| Technology & Equipment | Maintains honey purity, flavor, and beneficial properties with modern, gentle processing. |

| Quality Certifications | Ensures compliance with food safety standards, often required for major retail markets. |

| Location | Reduces transportation costs and time, minimizing the risk of product degradation. |

| Overall Cost Structure | Provides transparent pricing for accurate financial planning and protects profit margins. |

| Market Reputation | Indicates reliability and service quality through positive client testimonials and reviews. |

Ready to optimize your honey processing?

Your choice of processing partner is critical to your apiary's success. At HONESTBEE, we supply the high-quality beekeeping supplies and equipment that commercial apiaries and distributors rely on for efficient, large-scale operations.

We understand the needs of a growing business. Let us help you build a more productive and profitable operation.

Contact HONESTBEE today to discuss your wholesale equipment needs and find the right solutions for your business.

Visual Guide

Related Products

- 10L Stainless Steel Electric Honey Press Machine

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Stainless Steel Double Layer Honey Strainer Sieve Filters

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

People Also Ask

- What are the typical features and working principles of a bucket honey press? Optimize Your Honey Extraction

- How should a honey press be cleaned after use? Essential Hygiene & Wax Recovery Tips

- What are the material advantages of using a stainless steel honey press? Ensure Pure, Lead-Free Honey Extraction

- What are the benefits of the screw design in a stainless steel honey pump? Preserve Honey Quality and Integrity

- What are the key features of a honey press? Maximize Yield with Durable, Efficient Extraction