The three main applications for an electric double boiler in beeswax processing are processing honey-laden cappings, performing secondary wax cleaning and purification, and melting solid wax blocks for candlemaking or other crafts. Each application leverages the boiler's ability to provide gentle, controlled, and indirect heat.

The core value of an electric double boiler is not simply melting wax, but doing so with precision and safety. Its indirect heating method is the key to preventing scorching, discoloration, and fire risk, thereby preserving the quality and integrity of the final beeswax product.

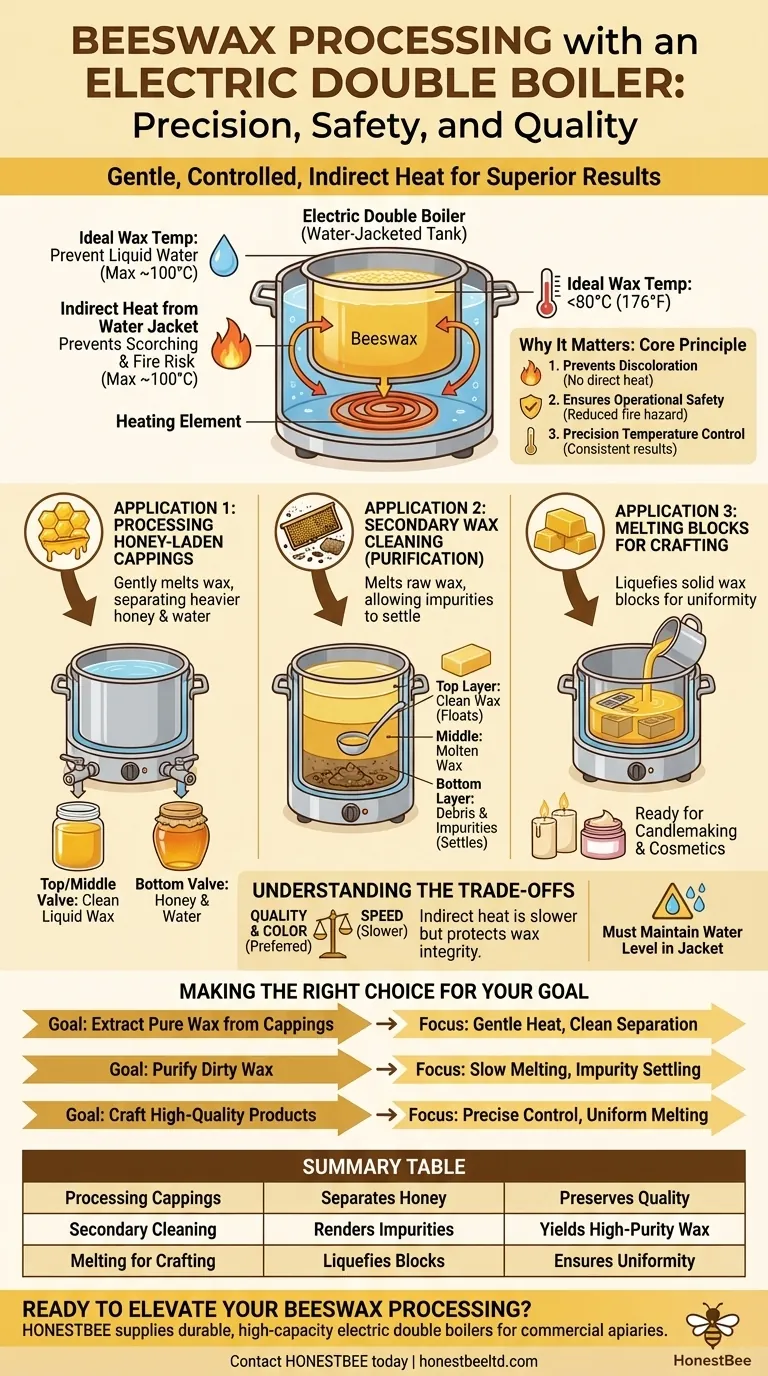

The Core Principle: Why Indirect Heat is Essential

Beeswax is a delicate material that is easily damaged by aggressive, direct heat. An electric double boiler solves this problem by using a water jacket to heat the main tank, ensuring the wax never comes into contact with a super-hot heating element.

Preventing Scorching and Discoloration

Direct heat can easily overheat and scorch beeswax, giving it a dark, burnt color and an unpleasant odor.

The ideal temperature for processing beeswax should not exceed 80°C (176°F) to prevent this discoloration. The water in a double boiler naturally caps the maximum temperature at its boiling point of 100°C (212°F), providing a critical safety buffer.

Ensuring Operational Safety

Beeswax is flammable and has a flashpoint. Applying direct heat, especially if left unattended, can raise the temperature to a dangerous level, creating a significant fire hazard.

An electric double boiler's indirect heating provides a much safer, regulated environment, making the entire process less risky.

Achieving Precision Temperature Control

Modern electric double boilers automatically cycle the heating element on and off. This intelligent operation maintains a stable, consistent temperature within the water jacket.

This level of control is crucial for achieving predictable, high-quality results every time you work with your wax.

The Three Primary Applications Explained

Each of the main applications takes advantage of the double boiler's gentle heating to separate materials or prepare the wax for a final product.

Application 1: Processing Cappings

When harvesting honey, the wax cappings are sliced off the comb. These cappings are saturated with honey.

The double boiler gently melts the wax, causing the heavier honey and water to separate and sink. This mixture can then be drained from a valve at the bottom of the tank, while the clean, liquid wax is siphoned from a valve in the middle.

Application 2: Secondary Wax Cleaning

Old combs or raw, unprocessed wax often contain honey, bee parts, and other debris. This process is often called rendering or purification.

By melting this raw material in the double boiler, the clean wax melts and floats. The heavier "junk" settles to the bottom of the tank, and any lighter dross can be skimmed from the top. The purified wax is then collected from the middle layer.

Application 3: Melting Blocks for Candlemaking

For artisans making candles, balms, or polishes, starting with clean, solid blocks of beeswax is common.

The double boiler provides the perfect environment to melt these blocks into a liquid state, ready for pouring. The stable temperature ensures the wax is homogenous and free of hot spots, which is critical for creating high-quality final products.

Understanding the Trade-offs

While highly effective, the double boiler method is a deliberate choice that involves specific trade-offs compared to other methods.

Quality Over Speed

The primary trade-off is speed. Indirect heating is inherently slower than applying direct heat. However, this slower, more controlled process is precisely what protects the quality and color of the beeswax.

Water Management is Key

The system relies on the water in the outer jacket. You must ensure this water level is maintained and does not boil dry, as this would eliminate the safety buffer and could cause the wax temperature to rise rapidly.

Making the Right Choice for Your Goal

Your specific goal will determine how you leverage the electric double boiler's capabilities.

- If your primary focus is extracting pure wax from honey-filled cappings: Use the gentle heat to liquefy the wax, enabling a clean separation from the honey without damaging its flavor or color.

- If your primary focus is purifying wax from old, dirty comb: Leverage the slow, stable melting to allow impurities to fully settle out, yielding a much cleaner final block of wax.

- If your primary focus is crafting high-quality candles or cosmetics: Rely on the precise temperature control to melt wax blocks uniformly, ensuring a consistent product free from scorching or discoloration.

Mastering the electric double boiler is about prioritizing the quality and safety of your beeswax, ensuring a superior result every time.

Summary Table:

| Application | Key Function | Primary Benefit |

|---|---|---|

| Processing Cappings | Separates honey from wax | Preserves honey quality and wax color |

| Secondary Wax Cleaning | Renders impurities from old comb | Yields high-purity, clean beeswax |

| Melting Blocks for Crafting | Liquefies solid wax blocks | Ensures uniform melting for candles & cosmetics |

Ready to elevate your beeswax processing?

For commercial apiaries and beekeeping equipment distributors, HONESTBEE supplies the durable, high-capacity electric double boilers essential for achieving consistent, high-quality wax. Our wholesale-focused operations provide the reliable equipment you need to scale your production while safeguarding your valuable product.

Contact HONESTBEE today to discuss your commercial beekeeping supply needs.

Visual Guide

Related Products

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

People Also Ask

- What are the recommendations for processing high-quality beeswax? Achieve Maximum Purity and Value

- What is the process for separating beeswax from honey? A Beekeeper's Guide to Rendering Pure Wax

- What is the function of professional beeswax purification and refining equipment? Boost Trade Value & Purity

- What are the main benefits of using an electric wax warmer? Enjoy a Safer, More Consistent Home Fragrance

- What types of beeswax melters are available for different scales of beekeeping? Solar vs. Electric Melters Compared

- What is the proper way to store processed beeswax? Expert Guide to Maintaining Wax Purity and Quality

- What should be done immediately after beeswax has completely melted? Essential Steps for Success

- What is the process of rendering beeswax? A Guide to Purifying Wax with Gentle Heat