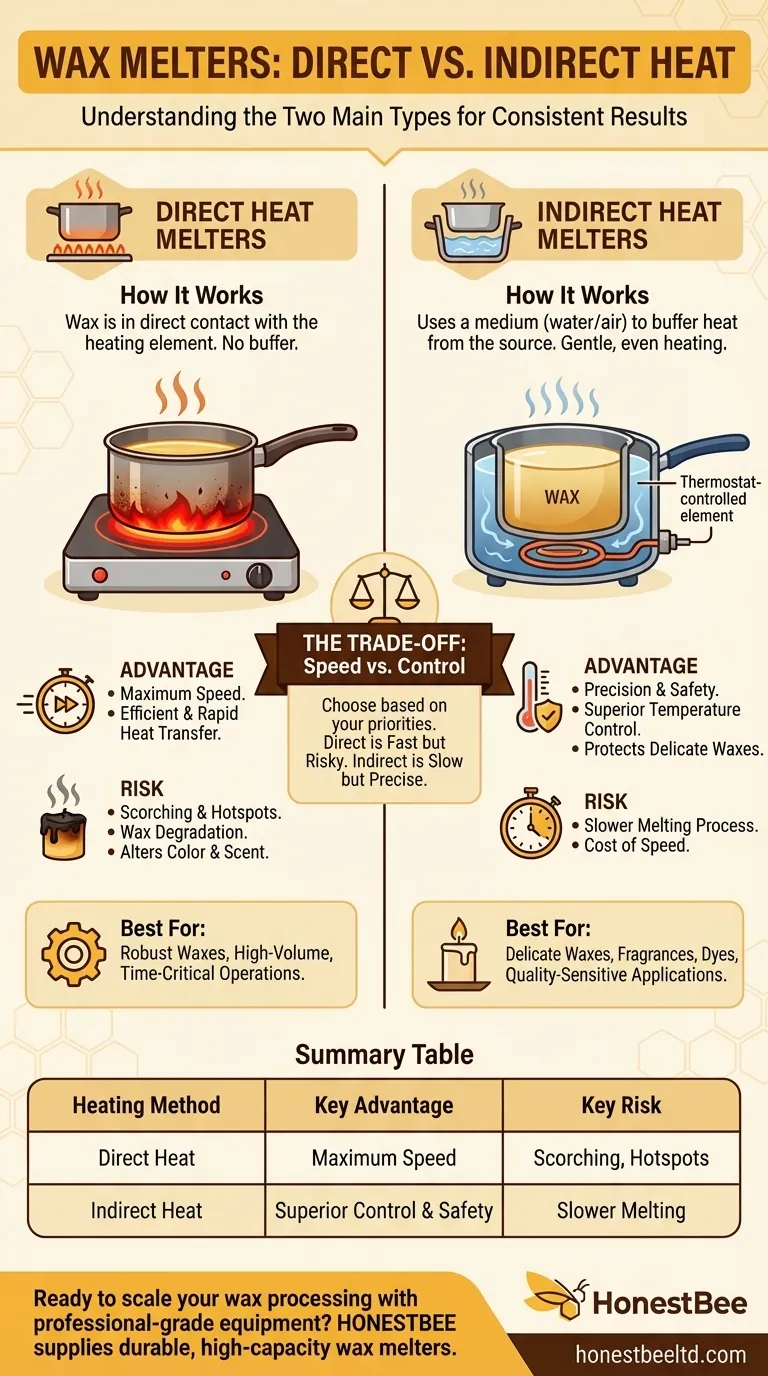

At their core, all wax melters can be classified into two fundamental types based on how they apply heat: direct heat melters and indirect heat melters. While other terms exist, they almost always describe a specific variation of one of these two primary methods. Understanding this distinction is the key to controlling your process and achieving consistent results.

The choice between a wax melter is not about which is "better," but about managing the trade-off between heating speed and temperature control. Direct heat is fast but risks scorching the wax, while indirect heat offers safety and precision at the cost of speed.

Direct Heat Melters: Speed and Simplicity

Direct heat is the most straightforward method of melting wax. It involves placing the wax in a vessel that is in direct contact with a heating element.

How They Work

Imagine placing a pot of solid wax directly on an electric stovetop or over a flame. The heat source transfers energy straight into the bottom of the pot, which then melts the wax it touches.

The Primary Advantage: Speed

Because there is no buffer, heat transfer is very efficient and rapid. This makes direct heat melters the fastest way to liquefy a batch of wax, which can be beneficial for high-volume operations where time is critical.

The Major Risk: Scorching and Hotspots

This speed comes at a price. The direct contact creates intense hotspots at the bottom of the melting vessel. This can easily scorch or burn the wax, altering its color, scent, and performance, especially for sensitive waxes used in candle-making.

Indirect Heat Melters: Precision and Safety

Indirect heat melters are designed to provide gentle, even heating by using a medium—typically water or air—to buffer the wax from the direct heat source.

The Foundational Method: The Double Boiler

The most common and accessible form of indirect heating is a double boiler. This involves one pot for the wax placed inside a larger pot containing water. As the water heats up, it gently and evenly transfers that heat to the inner pot, melting the wax without creating dangerous hotspots.

This method is highly recommended for beginners and hobbyists due to its safety and low cost.

The Professional Standard: The Water-Jacket Melter

A water-jacket melter is essentially a purpose-built, professional-grade double boiler. It consists of an inner tank for wax surrounded by an outer "jacket" filled with water. A thermostat-controlled element heats the water, which in turn melts the wax at a precise, stable temperature.

These devices offer the ultimate in control and are the standard for any serious candle-making or packaging operation where wax quality is paramount.

Understanding the Trade-offs

Choosing the right melter requires you to balance your priorities. There is no single "best" option, only the one that is best suited for your specific application.

Speed vs. Quality Control

Direct heat offers maximum speed but minimal control, making it suitable only for robust waxes where a risk of discoloration is acceptable. Indirect heat is slower but provides the precise temperature control needed to protect delicate waxes, fragrances, and dyes.

Scale and Capacity

Simple double boilers are excellent for small, experimental batches. Purpose-built direct heat pots may offer slightly more capacity. For scaling up production while maintaining quality, a dedicated water-jacket melter is the only reliable choice.

A Note on Power Sources

You will also see melters described by their power source, such as electric, solar, or steam. This is a separate classification from the heating method. An electric melter, for instance, could use either direct heat (like a hot plate) or indirect heat (like a water-jacket melter). Solar and steam melters are more specialized, often used in beekeeping for processing beeswax.

Making the Right Choice for Your Goal

Your application dictates the correct tool for the job.

- If your primary focus is learning or small-scale hobby projects: Start with a simple double boiler setup. It is the safest and most forgiving method for protecting your materials.

- If your primary focus is scaling up production for a business: Invest in a thermostat-controlled water-jacket melter. This ensures product consistency and quality control batch after batch.

- If your primary focus is melting large volumes of robust wax at maximum speed: A direct heat melter may be a viable option, but only if you can tolerate the inherent risk of hotspots and potential wax degradation.

Choosing the right heating method is the first step toward mastering your craft and ensuring consistent, high-quality results every time.

Summary Table:

| Heating Method | How It Works | Best For | Key Advantage | Key Risk |

|---|---|---|---|---|

| Direct Heat | Wax is in direct contact with the heating element. | High-speed melting of robust waxes. | Maximum speed. | Scorching, hotspots, wax degradation. |

| Indirect Heat | Uses a medium (water/air) to buffer heat from the source. | Precise, safe melting for quality-sensitive applications. | Superior temperature control and safety. | Slower melting process. |

Ready to scale your wax processing with professional-grade equipment? At HONESTBEE, we supply durable, high-capacity wax melters and beekeeping supplies to commercial apiaries and distributors. Our wholesale-focused operations ensure you get the reliable equipment you need to maintain product quality and efficiency. Contact our experts today to discuss the best melter for your operation!

Visual Guide

Related Products

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

People Also Ask

- How does the machine flatten the beeswax? A Guide to Roller and Press Methods

- What is the process for purifying beeswax after removing it from a hive? A Simple Two-Stage Method for Pure Wax

- What are the steps involved in preparing wax sheets for milling? Master Temperature Control for Perfect Foundation

- What are the advantages of using industrial wax melters for beeswax? Achieve Scalable, Safe, and Consistent Production

- How to clean wax after extracting honey? Master the Cold Wash vs. Melting Methods