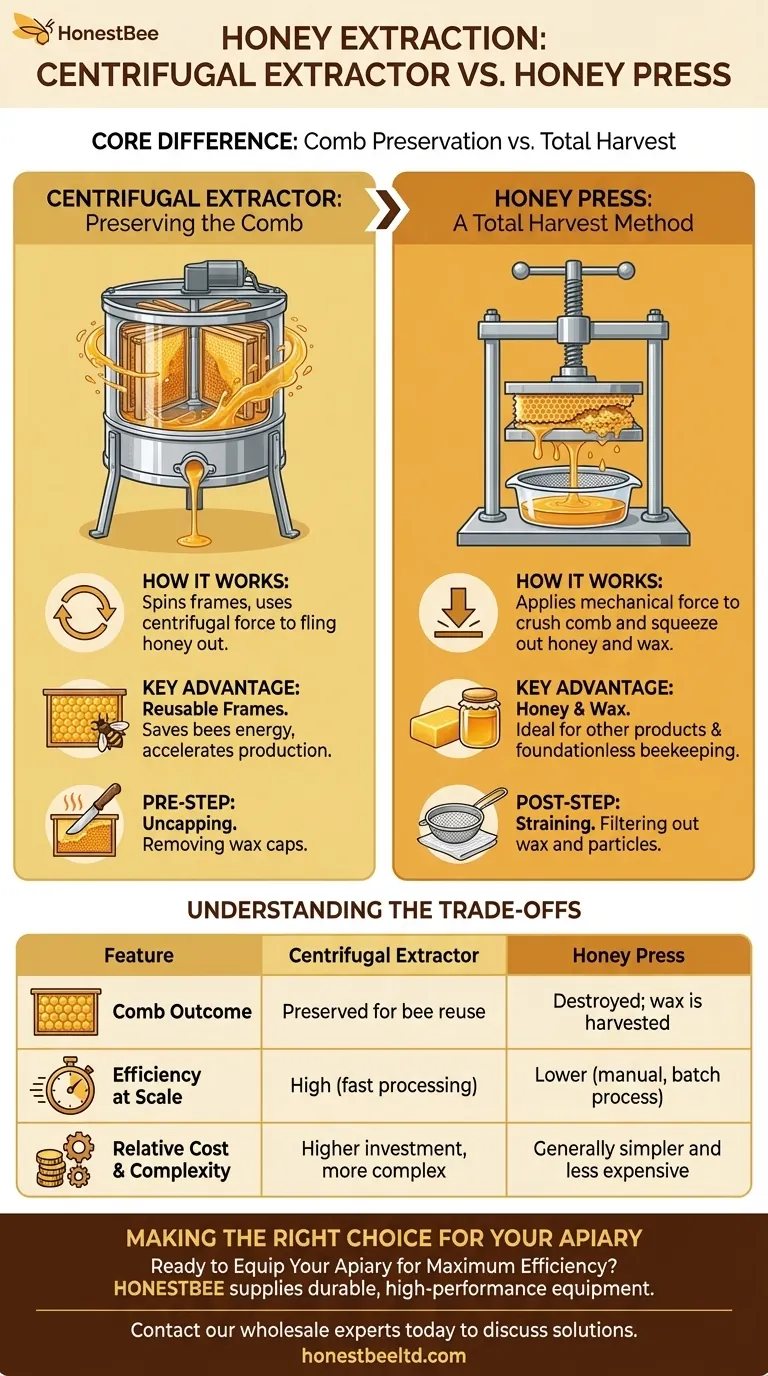

The two most popular types of machines for honey extraction are the centrifugal extractor and the honey press. A centrifugal extractor spins frames to sling honey out, preserving the wax comb for reuse, while a honey press crushes the entire comb to squeeze out both honey and wax.

Your choice between a centrifugal extractor and a honey press hinges on one key factor: whether you want to preserve your beeswax comb for the bees to reuse or harvest both the honey and wax at the same time.

The Centrifugal Extractor: Preserving the Comb

A centrifugal extractor is the most common piece of equipment for beekeepers who plan to manage their hives for continuous honey production over many years.

How It Works

This machine operates on the principle of centrifugal force. Frames full of honey are placed inside a drum, which then spins at high speed. The force flings the honey out of the cells, where it runs down the walls of the drum and collects at the bottom.

The Key Advantage: Reusable Frames

The primary benefit of a centrifugal extractor is that it extracts honey without destroying the delicate wax comb. This is a massive energy-saver for the bees, who can immediately start refilling the preserved comb instead of spending resources to rebuild it from scratch.

The Necessary Pre-Step: Uncapping

Before frames can be placed in an extractor, the wax caps that seal each cell must be removed. This is typically done with a heated electric knife, a cold uncapping knife, or a roller, which slices off the very top layer of wax.

The Honey Press: A Total Harvest Method

A honey press is a simpler machine that serves a different purpose, often favored by natural beekeepers or those who value the wax harvest as much as the honey.

How It Works

Instead of spinning, a honey press uses mechanical force to crush and squeeze the honey and comb together. The comb is placed in the press, and a plate is screwed down, forcing the liquid honey out through a filter or screen while retaining the bulk of the wax.

The Key Advantage: Processing Honey and Wax

With a press, you are not just harvesting honey; you are also harvesting the entire beeswax comb. This method is ideal for those who want to render the wax for other products like candles or cosmetics. It is also the necessary method for foundationless beekeeping, where combs may not be uniform enough for an extractor.

The Necessary Post-Step: Straining

Because pressing mixes wax, pollen, and other hive particles directly into the honey, thorough straining is essential. The collected honey is often gently warmed in a water bath to reduce its viscosity and then passed through fine sieves or cheesecloth to produce a clean final product.

Understanding the Trade-offs

The choice between these two methods is not about which is "better," but which one aligns with your goals and beekeeping philosophy.

Comb Preservation: The Major Dividing Line

The decision to preserve or destroy the comb is the most significant factor. Reusing comb accelerates honey production and reduces stress on the colony. Destroying it provides a valuable secondary product (beeswax).

Equipment Simplicity and Cost

Honey presses are mechanically simpler, often smaller, and generally less expensive than centrifugal extractors. Extractors are larger, have moving parts, and represent a more significant investment, especially for high-capacity or motorized models.

Efficiency at Scale

For anyone managing more than a few hives, the centrifugal extractor is far more efficient for processing large quantities of honey quickly. Pressing is a more manual and time-consuming batch process.

Making the Right Choice for Your Apiary

Your decision should be based on your specific goals as a beekeeper.

- If your primary focus is maximizing honey production and colony efficiency: A centrifugal extractor is the standard choice because reusing drawn comb gives your bees a significant head start.

- If your primary focus is harvesting both honey and beeswax, or you practice foundationless beekeeping: A honey press is a simple and effective method that allows you to process the entire contents of the frame.

Understanding this fundamental difference in process empowers you to select the right tool for your specific beekeeping goals.

Summary Table:

| Feature | Centrifugal Extractor | Honey Press |

|---|---|---|

| Primary Method | Spins frames to fling honey out | Crushes comb to squeeze honey out |

| Comb Outcome | Preserved for bee reuse | Destroyed; wax is harvested |

| Best For | Maximizing honey production & efficiency | Harvesting honey & beeswax, foundationless beekeeping |

| Efficiency at Scale | High (fast processing) | Lower (manual, batch process) |

| Relative Cost & Complexity | Higher investment, more complex | Generally simpler and less expensive |

Ready to Equip Your Apiary for Maximum Efficiency?

Whether you're a commercial apiary focused on high-volume honey production or a distributor supplying the beekeeping community, choosing the right extraction equipment is critical. HONESTBEE supplies durable, high-performance centrifugal extractors and honey presses designed for the demands of serious beekeepers.

We help you make the right investment to boost your harvest and streamline your operation. Contact our wholesale experts today to discuss the best extraction solutions for your business.

Visual Guide

Related Products

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- HONESTBEE 8 Frame Electric and Manual Three Use Honey Extractor

- Stainless Steel 3 Frame Manual Honey Extractor Spinner for Bee Honey Extraction

People Also Ask

- What role does a manual stainless steel centrifugal honey extractor play in productivity? Quantify Mite Treatment Success

- What is a fun and easy alternative to using a honey extractor for harvesting honey? Try the Crush and Strain Method

- How is honey separated from the frames after they are uncapped? Efficient Extraction Methods for High Yields

- What is the function of industrial honey extractors? Boost Yields with Efficient Centrifugal Separation

- How to extract honey by hand? A Guide to Crush & Strain vs. Manual Extractors

- What is the operational principle of industrial honey extraction machines? Maximize Efficiency and Profitability

- How does a honey extractor function? Master the Art of Efficient Centrifugal Honey Harvesting

- What is a tangential honey extractor? A simple, cost-effective tool for small-scale beekeepers