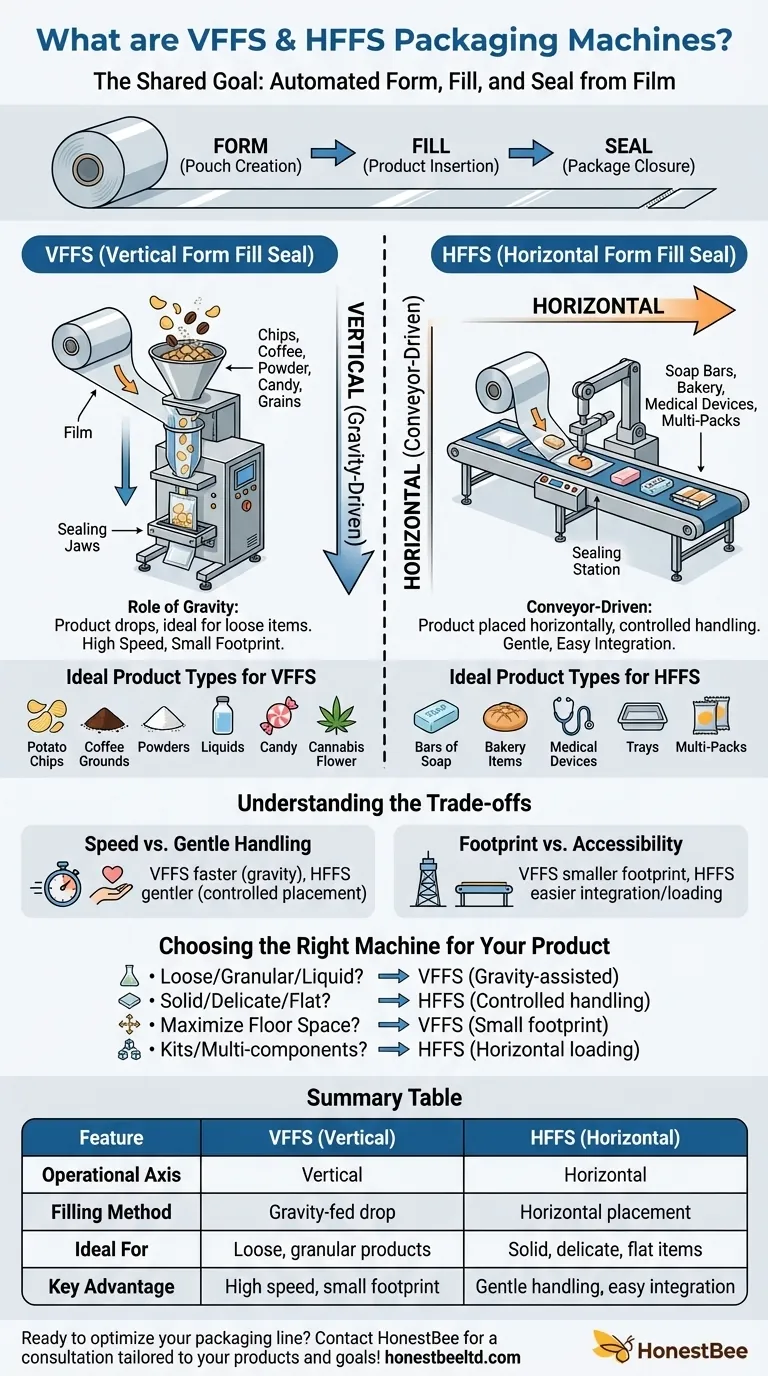

In automated packaging, VFFS stands for Vertical Form Fill Seal, while HFFS stands for Horizontal Form Fill Seal. Both are highly efficient machines that create, fill, and seal flexible packaging from a single roll of film. The core difference between them is their operational orientation, which dictates the types of products they are best suited to handle.

The choice between VFFS and HFFS is fundamentally a question of product handling. VFFS machines leverage gravity for filling, making them ideal for loose items like powders and snacks. HFFS machines move products horizontally, offering the gentle control needed for solid, flat, or delicate items.

The Shared Goal: Form, Fill, and Seal

Before diving into their differences, it's important to understand what both machine types have in common. They are complete, automated packaging systems designed for speed and consistency.

The Core Process

Both VFFS and HFFS machines start with a large, flat roll of packaging film. The machine forms this film into a pouch, fills the pouch with your product, and then seals it shut, all in one continuous motion.

This automated process drastically increases production speed and reduces manual labor compared to using pre-made bags.

The Vertical Approach: Understanding VFFS

A Vertical Form Fill Seal machine operates, as the name implies, on a vertical axis. It is the workhorse for many products found in a grocery store.

The Role of Gravity

In a VFFS system, the film is pulled downwards over a "forming tube," creating the shape of the bag. The product is then dropped from a dispenser (like a weigher or auger filler) located above the machine directly into the open bag.

Once filled, the machine creates the top seal of that bag, which simultaneously forms the bottom seal of the next bag in the sequence.

Ideal Product Types for VFFS

Because the product is dropped, VFFS is perfectly suited for durable, loose, or granular products that can be easily dispensed by weight or volume.

This includes items like potato chips, coffee grounds, powders, liquids, grains, candy, and cannabis flower.

The Horizontal Approach: Understanding HFFS

A Horizontal Form Fill Seal machine performs the same three tasks—forming, filling, and sealing—but does so along a horizontal plane.

A Conveyor-Driven Process

In an HFFS system, the pouch is formed and then travels along a horizontal conveyor. The product is not dropped but is instead pushed or carefully placed into the open pouch.

This method provides significantly more control over how the product enters and is positioned within the package.

Ideal Product Types for HFFS

The gentle, controlled nature of HFFS makes it the superior choice for products that are solid, delicate, or need to be handled carefully.

This includes items like bars of soap, bakery items, medical devices, products sold in trays, or multi-packs of individually wrapped items.

Understanding the Trade-offs

Neither machine is inherently superior; they are simply designed for different applications. The choice involves clear trade-offs.

Speed vs. Gentle Handling

VFFS machines are often capable of higher speeds because gravity-assisted filling is extremely fast. HFFS machines may operate at a slower cycle time to accommodate the more delicate horizontal loading process.

Footprint vs. Accessibility

Due to their vertical construction, VFFS machines typically have a much smaller factory floor footprint than the long, horizontal layout of an HFFS machine. However, the horizontal nature of an HFFS machine can make it easier to integrate with other conveyor systems or manual loading stations.

Product Versatility

VFFS is the clear winner for any loose, flowable product. HFFS, on the other hand, excels with single, solid items, irregularly shaped products, or packs containing multiple distinct components that must be loaded together.

Choosing the Right Machine for Your Product

Your product's physical characteristics will almost always dictate the correct machine choice. A simple analysis can quickly point you in the right direction.

- If your primary focus is on loose, granular, or liquid products: A VFFS machine is the correct choice due to its efficient, gravity-assisted filling.

- If your primary focus is on solid, flat, or delicate items: An HFFS machine provides the gentle, controlled handling necessary to prevent product damage.

- If your primary focus is maximizing floor space in your facility: A VFFS machine's vertical orientation typically offers a significantly smaller footprint.

- If your primary focus is packaging kits or multiple solid components: An HFFS machine's horizontal layout makes manual or automated multi-component loading more feasible.

Understanding this core operational difference—vertical drop versus horizontal placement—is the key to selecting the ideal packaging solution for your goal.

Summary Table:

| Feature | VFFS (Vertical) | HFFS (Horizontal) |

|---|---|---|

| Operational Axis | Vertical | Horizontal |

| Filling Method | Gravity-fed drop | Horizontal placement |

| Ideal For | Loose, granular products (chips, powders) | Solid, delicate, flat items (soap, bakery, devices) |

| Key Advantage | High speed, small footprint | Gentle handling, easy integration |

Ready to optimize your packaging line? HONESTBEE supplies high-performance VFFS and HFFS packaging machines and beekeeping equipment to commercial apiaries and distributors. Our wholesale-focused operations ensure you get the reliable, efficient machinery your business needs to scale. Contact our experts today for a consultation tailored to your products and goals!

Visual Guide

Related Products

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Professional Durable Customizable Blister Packing Machine

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Professional Water Cooled Induction Sealing Machine for Bottles and Containers

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

People Also Ask

- How do modern honey extraction and automated filling equipment contribute to honey export competitiveness?

- What are the technical requirements for organic honey equipment? High-Purity Extraction & Bottling Standards

- What equipment is used for bottling honey cleanly and efficiently? Professional Filling Solutions for Every Scale

- How does an industrial-grade honey sachet packaging machine assist beekeepers in accessing public institution markets?

- Why are food-grade sterile containers and professional sealing equipment required for honey storage? Protect Your Quality