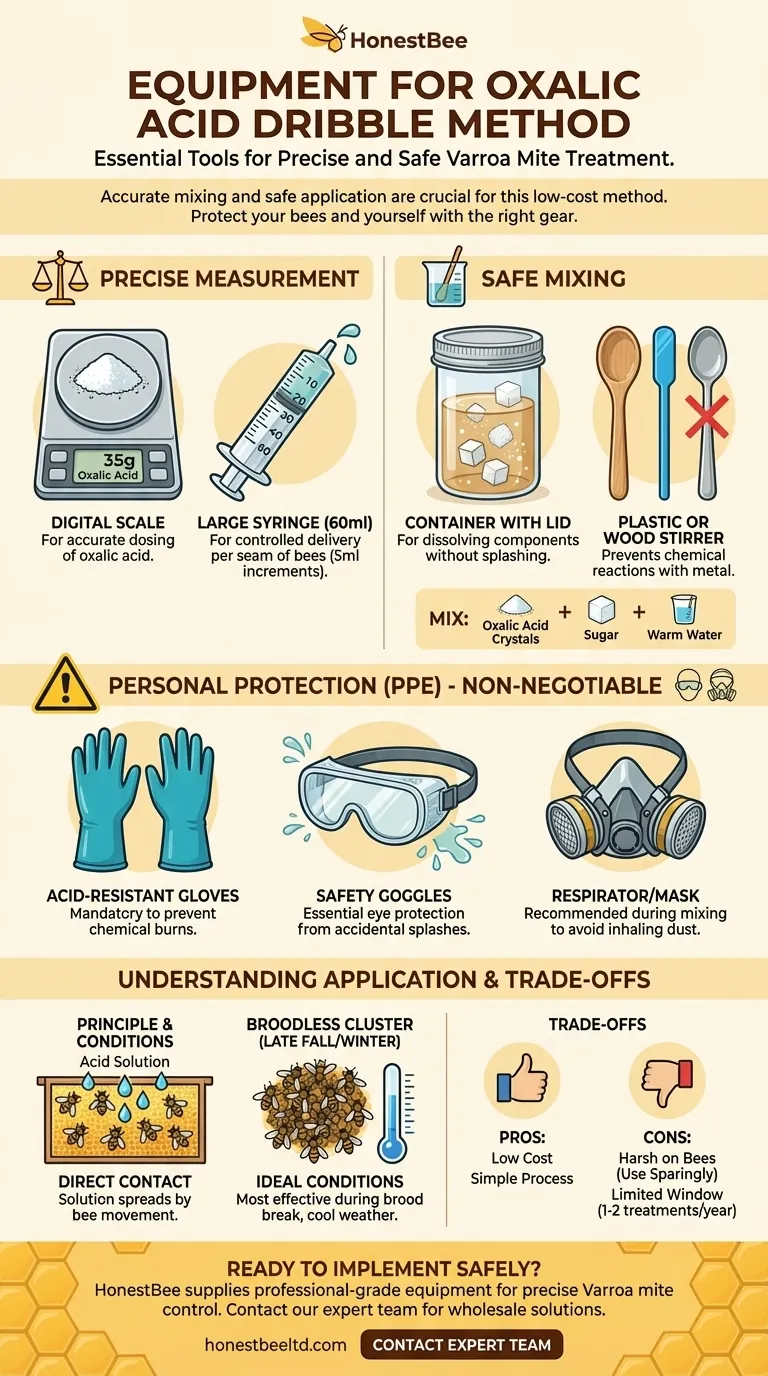

To properly use the dribble method, you need a specific set of tools for accurate mixing and safe application. The essential equipment includes a digital scale for weighing oxalic acid dihydrate, a container with a tight-fitting lid, a plastic or wood stirrer, a large syringe for dosing, and non-negotiable personal protective equipment (PPE). These items ensure you can prepare and apply the solution correctly while protecting yourself from the corrosive acid.

The oxalic acid dribble method is a low-cost and straightforward Varroa mite treatment, but its effectiveness is entirely dependent on precise measurement and application timing. Its simplicity can be deceptive, as improper use can be harmful to your bees.

Assembling Your Dribble Method Toolkit

Each piece of equipment serves a critical function in either the safety or efficacy of the treatment. Using incorrect tools can lead to an ineffective dose or, worse, personal injury.

For Precise Measurement

The difference between a treatment and a toxin is the dose. For oxalic acid, this is paramount.

Your digital scale is the most important tool for getting the mixture right. You will be measuring a small amount of oxalic acid (typically 35g for a standard 1-liter solution), and even small errors can significantly alter the concentration.

A large syringe (60ml is common) is used for application. These are often marked in 5ml increments, which is the standard dose applied per seam of bees. This allows for controlled, accurate delivery directly onto the colony.

For Safe Mixing

The mixing process requires care and the right materials to avoid chemical reactions and ensure a stable solution.

You will need a clean mixing container, preferably made of glass or acid-resistant plastic, with a tight-fitting lid. This is for mixing the acid, sugar, and water. A sealed lid allows you to dissolve the components by shaking without risk of splashing.

Use only a plastic or wood stirrer. Oxalic acid is corrosive to metals, and a metal spoon can contaminate your solution and be damaged in the process.

The other components of the mixture are oxalic acid dihydrate crystals, sugar, and warm, non-chlorinated water. The sugar makes the solution sticky, helping it adhere to the bees, while the warm water helps dissolve both the sugar and the acid crystals.

For Personal Protection (Non-Negotiable)

Oxalic acid is a corrosive organic acid. It is hazardous if inhaled, ingested, or absorbed through the skin, and can cause severe eye damage.

Acid-resistant gloves (such as nitrile or latex) are mandatory to prevent chemical burns on your hands.

Safety goggles are essential to protect your eyes from accidental splashes, which can have devastating consequences.

A respirator or mask rated for organic acids/vapors is highly recommended during the mixing phase to avoid inhaling any airborne acid dust.

Understanding the Application Context

The dribble method is not a year-round solution. It is a specific tool for a specific time, and understanding the "why" behind its application is key to success.

The Principle: Direct Contact

This method works by trickling the acid solution directly onto the bees. The bees, through their natural movement and grooming, spread the solution throughout the cluster. The acid is lethal to the Varroa mites it contacts.

The Ideal Conditions: A Broodless Cluster

Oxalic acid treatment only kills phoretic mites—the mites on the bodies of adult bees. It does not penetrate capped brood, where the majority of mites reproduce.

Therefore, the dribble method is most effective during a natural brood break, typically in late fall or early winter. Applying it when the queen is still laying heavily will leave the mite population in the brood cells untouched, rendering the treatment ineffective.

Cooler weather, when bees are in a tight cluster, is also ideal. This ensures the solution is distributed efficiently among the bees and not just dripped into empty parts of the hive.

Understanding the Trade-offs

Like any hive treatment, the dribble method has clear benefits and significant drawbacks that every beekeeper must weigh.

Pro: Low Cost and Simplicity

The primary appeal of the dribble method is its low cost. The required equipment and ingredients are inexpensive and readily available. The process itself is straightforward and requires no specialized power sources.

Con: Harsh on Bee Exoskeletons

The major drawback is that the acid solution is harsh on the bees themselves. It can damage their exoskeleton (cuticle) and disrupt their natural gut biome. For this reason, it must be used sparingly.

Con: Limited Application Window

Because of its harshness, a single colony should only be treated with the dribble method once per broodless period, and at most twice per year. Over-application will stress the colony and can lead to a noticeable loss of bees, especially heading into winter. The maximum dose for a colony is typically 50ml total.

Is the Dribble Method Right for Your Apiary?

Making the correct choice requires you to evaluate your goals, the season, and the scale of your operation.

- If your primary focus is a low-cost, late-fall treatment for a few hives: The dribble method is a perfectly viable option, provided you adhere strictly to the dosage, timing, and safety protocols.

- If you need to treat during the main season or have many hives: Consider an alternative like oxalic acid vaporization, which is faster to apply per-hive and is generally considered gentler on the bees, allowing for multiple treatments if needed.

Choosing the right mite treatment is about balancing effectiveness with the long-term health of your colony.

Summary Table:

| Category | Essential Equipment | Purpose |

|---|---|---|

| Precise Measurement | Digital Scale, Large Syringe (60ml) | Accurate dosing of acid and solution application per seam of bees. |

| Safe Mixing | Glass/Plastic Container with Lid, Plastic/Wood Stirrer | Prevents contamination and ensures a stable oxalic acid, sugar, and water solution. |

| Personal Protection (PPE) | Acid-Resistant Gloves, Safety Goggles, Respirator/Mask | Protects against corrosive acid during mixing and application. |

Ready to implement the dribble method safely and effectively?

As a commercial beekeeper or equipment distributor, you need reliable, high-quality supplies for precise Varroa mite control. HONESTBEE supplies professional-grade beekeeping equipment and supplies through wholesale-focused operations, ensuring you have the right tools for the job.

Let us help you protect your investment and maintain healthy colonies. Contact our expert team today to discuss your apiary's needs and explore our wholesale solutions.

Visual Guide

Related Products

- Adjustable Formic and Acetic Acid Dispenser for Bee Mite Treatment

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

- Plastic Chinese Queen Grafting Tool for Bee Queen Rearing

- Heavy-Duty Galvanized Steel W-Style Pallet Clip

- HONESTBEE Bee Frame Side Bar Forming Machine Precision Engineered for High-Volume Production Bee Frame Machine

People Also Ask

- How should Varroa mite treatments be integrated into the spring beekeeping schedule? Expert April-May Timing Guide

- Why is a high-precision larva and pupa extraction process required when analyzing Varroa mite reproductive success?

- How does a precision evaporative formic acid dispenser treat Varroa mites? Master Controlled Pest Management

- What unique benefits do formic acid evaporators offer for mite control? The Only Safe Solution During Honey Flow

- What is a beehive's inner cover and how is it used? Essential Guide for Hive Insulation and Ventilation