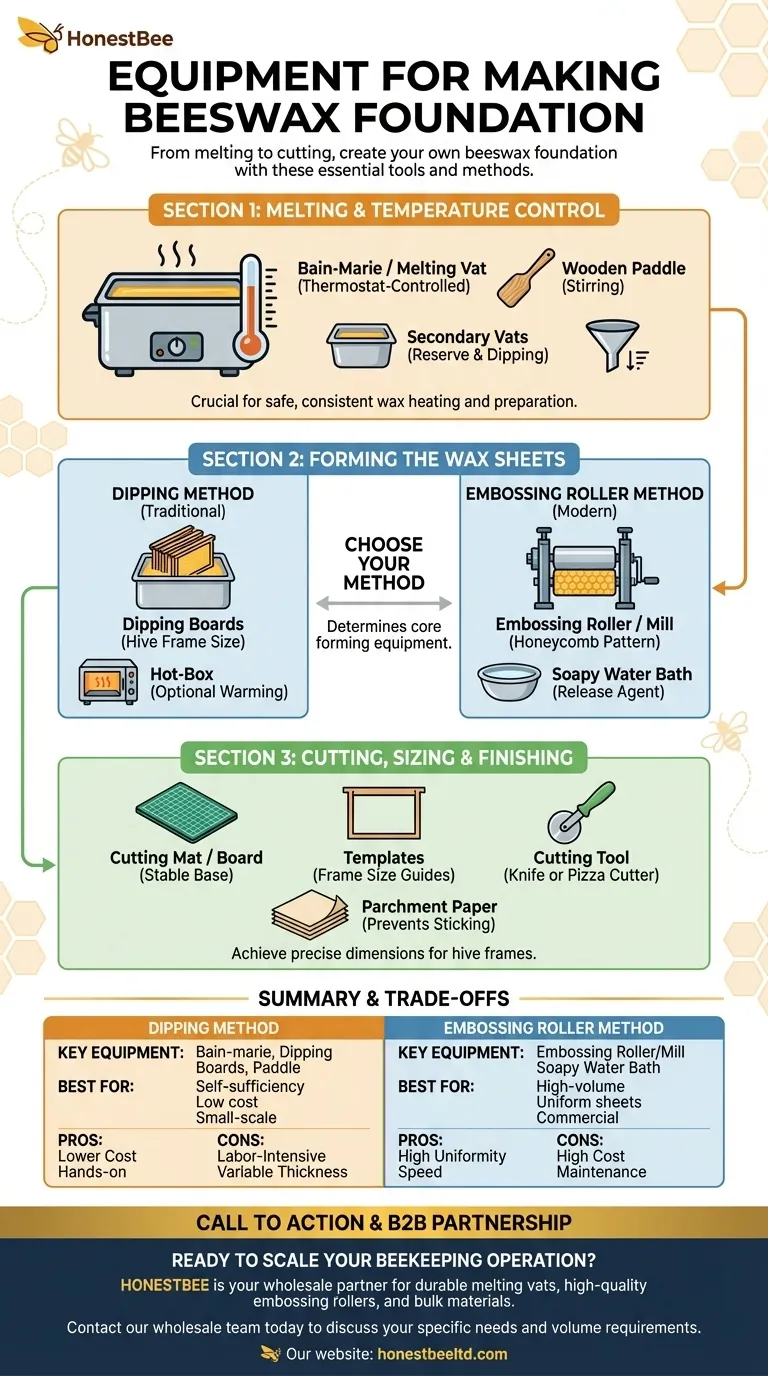

To make your own beeswax foundation, you will need equipment for three primary stages: melting the wax, forming it into sheets, and cutting it to size. The core components include a temperature-controlled melting vat or bain-marie, tools to form the sheets like dipping boards or an embossing roller, and implements like a cutting mat and knife for final sizing. Because commercial kits are not readily available, most of this equipment is part of a custom, do-it-yourself setup.

The specific equipment you need is determined by the production method you choose: the traditional dipping method or the more modern embossing roller method. Understanding the requirements of each is the key to assembling the right toolkit for your goals.

The Core Components of Foundation Making

Making foundation is a process, and each step requires specific tools. We can group the necessary equipment by its function in the workflow: melting, forming, and finishing.

Wax Melting and Temperature Control

This is the non-negotiable first step. Properly melted and filtered beeswax is the raw material for your foundation.

- Melting Vat or Bain-Marie: You need a container to melt the wax safely. A bain-marie (water bath) with a thermostat-controlled heating element provides the most consistent and gentle heat, preventing the wax from scorching.

- Secondary Vats: If using the dipping method, you will need at least two additional vats: one to hold the dipping boards and a second to maintain a reserve supply of melted wax.

- Wooden Paddle: A simple hardwood paddle is essential for stirring the wax to ensure even temperature distribution and to break up any solid pieces.

Forming the Wax Sheets

This is where the two primary methods diverge. Your choice here dictates the most significant equipment you will need.

- The Dipping Method: This traditional technique involves building up layers of wax on a board.

- Dipping Boards: Smooth pine or masonite boards are cut to the internal dimensions of your hive frames. These are repeatedly dipped into the wax to build up a sheet.

- Hot-Box (Optional): A heated box can be used to slightly warm the finished sheets, making them more pliable and easier to handle or emboss later.

- The Embossing Roller Method: This method creates perfectly patterned sheets from smooth wax "ribbons."

- Embossing Roller (or Mill): This is the most specialized piece of equipment. It's a heavy-duty roller with the classic honeycomb cell pattern engraved on its surface. As you feed a smooth sheet of wax through it, the pattern is imprinted.

- Soapy Water Bath: A bowl of soapy water (using phosphate-free dish soap) is used as a release agent. You apply it to the roller to prevent the wax from sticking.

Cutting, Sizing, and Handling

Once the sheets are formed, they must be cut to the precise dimensions of your hive frames.

- Cutting Mat or Board: A flat, durable surface is needed to protect your work table and provide a stable base for cutting.

- Templates: Thin masonite or wood boards cut to your exact frame sizes (e.g., deep, medium) serve as perfect guides for consistent cutting.

- Cutting Tool: A sharp knife or a round pizza cutter works exceptionally well for making clean, straight cuts through the wax sheets.

- Parchment Paper: Have a space covered with parchment paper ready to stack the finished sheets. The paper prevents them from sticking together.

Understanding the Trade-offs: Dipping vs. Rolling

Choosing your method is a strategic decision based on cost, desired quality, and production volume. Neither is universally "better," but one will be better for you.

The Dipping Method: Pros and Cons

This method is rooted in self-sufficiency and requires less specialized equipment.

Pros: The initial investment is significantly lower, as most of the equipment (vats, boards) can be built or repurposed. It gives you a deep, hands-on understanding of working with beeswax.

Cons: The process is more labor-intensive and requires significant practice to achieve sheets of consistent thickness. The final product may lack the perfect uniformity of milled foundation.

The Embossing Roller Method: Pros and Cons

This approach prioritizes consistency and a professional finish, mirroring commercially available foundation.

Pros: It produces highly uniform, perfectly embossed foundation that bees readily accept. Once you have a smooth wax ribbon, the embossing process is relatively fast.

Cons: The initial cost is very high. A quality foundation mill or embossing roller is a significant investment that may only be justifiable for large-scale or commercial-level production. The mill also requires careful cleaning and maintenance.

Making the Right Choice for Your Operation

Your goal as a beekeeper should guide your equipment decisions. There is no one-size-fits-all solution, only the right tool for your specific job.

- If your primary focus is self-sufficiency and low cost: Start with the dipping method, as you can create the entire setup with basic materials and a small budget.

- If your primary focus is producing high-volume, uniform foundation: Invest in a quality embossing roller, as it provides unmatched consistency and speed.

- If your primary focus is controlling your wax supply: Either method achieves this, but starting with dipping allows you to master handling wax before deciding on a larger investment.

By selecting the right equipment, you gain complete control over one of the most critical components in your beehive.

Summary Table:

| Method | Key Equipment | Best For |

|---|---|---|

| Dipping Method | Bain-marie, Dipping Boards, Wooden Paddle | Self-sufficiency, Low cost, Small-scale production |

| Embossing Roller Method | Embossing Roller/Mill, Soapy Water Bath | High-volume, Uniform sheets, Commercial production |

Ready to Scale Your Beekeeping Operation?

Whether you're a commercial apiary or a beekeeping equipment distributor, HONESTBEE is your trusted wholesale partner for high-quality beekeeping supplies. We provide the durable equipment and bulk materials you need to produce foundation efficiently and at scale.

We supply:

- Durable wax melting vats and temperature control systems

- High-quality embossing rollers and foundation mills for uniform production

- Bulk materials for dipping and cutting operations

Let us help you optimize your foundation production. Contact our wholesale team today to discuss your specific needs and volume requirements.

Visual Guide

Related Products

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

People Also Ask

- What specific equipment is required for making beeswax foundation? Essential Tools for High-Quality Production

- How is a manual honeycomb embossing machine designed for portability and storage? Compact Solutions for Beekeepers

- What are the advantages of the mold surface on a silicone beeswax foundation embossing machine? Efficiency & Durability

- What are the sequential stages of operation for a beeswax flatting and embossing machine? Master High-Quality Wax Sheets

- What are the portability features of the manual honeycomb embossing machine? Achieve On-Site Foundation Control

- What technical problem does a professional comb foundation machine solve? Boost Beekeeping Efficiency & Yield

- Why are wax foundation machines and casting molds necessary? Build Stronger Hives and Maximize Honey Yields

- What is the ideal room temperature for milling wax foundation? Expert Tips for Perfect Thermal Management