To be suitable for honey, a packaging machine must address the product's high viscosity and sensitivity to temperature. Key features include precision filling mechanisms like piston fillers, specialized nozzles with drip-preventing shut-off valves and suck-back devices, and double-layer insulated barrels to maintain honey's consistency and purity. The machine must also be versatile enough to handle various container types, such as glass or plastic jars and bottles.

The challenge with honey is not just packaging a liquid; it's about managing a thick, temperature-sensitive product without sacrificing accuracy, speed, or quality. The right machine combines precise volume control with features that protect the honey's natural integrity.

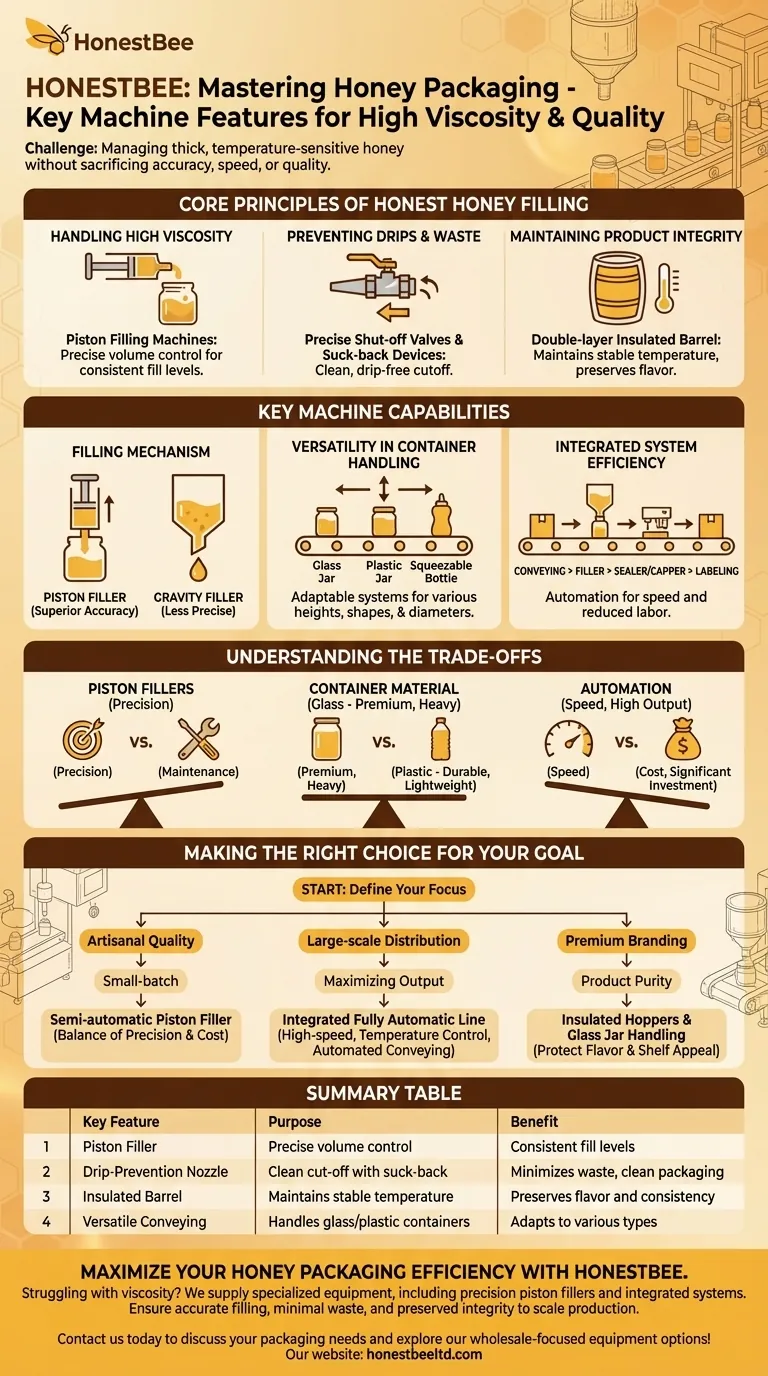

Core Principles of Honey Filling

Understanding the unique properties of honey is the first step in selecting the right equipment. A standard liquid filler is often insufficient for this task.

Handling High Viscosity

Honey's thickness, or viscosity, changes with temperature and makes it difficult to portion accurately.

Piston filling machines are exceptionally well-suited for this. They use a cylinder and piston to draw in a precise volume of honey and then dispense it, ensuring consistent fill levels regardless of minor viscosity changes.

Preventing Drips and Waste

Because honey is thick and sticky, drips from the filling nozzle can create significant mess, product waste, and sealing issues.

Effective honey fillers use precise shut-off valves at the nozzle to stop the flow instantly. High-end models also incorporate a suck-back device, which pulls a small amount of honey back into the nozzle after each fill to guarantee a clean, drip-free cutoff.

Maintaining Product Integrity

Honey's quality, concentration, and purity can be affected by temperature fluctuations.

A double-layer insulated barrel or hopper is a critical feature. This helps maintain a stable temperature, ensuring the honey flows consistently and its delicate flavor profile and beneficial properties are preserved throughout the packaging process.

Key Machine Capabilities

Beyond the core principles, the machine's overall design determines its operational efficiency and adaptability to your specific needs.

Filling Mechanism: Piston vs. Gravity

You will encounter two primary types of fillers for honey.

A piston filler offers superior accuracy and is the industry standard for viscous products. It provides positive displacement, meaning it dispenses a set volume every time.

A gravity filler relies on the weight of the honey to fill containers. While simpler and often less expensive, it is less precise for honey, as flow rates can vary with temperature and the level of honey in the hopper.

Versatility in Container Handling

Your machine must accommodate your chosen packaging, whether that is glass jars, plastic jars, or squeezable plastic bottles.

A good system features an adaptable conveying system and adjustable filling heads that can handle a range of container heights, shapes, and opening diameters.

Integrated System Efficiency

For larger operations, efficiency comes from automation.

Look for machines that integrate filling with subsequent processes. A complete line often includes a conveying system that moves containers seamlessly from the filler to a sealer or capper and finally to a labeling machine.

Understanding the Trade-offs

No single solution is perfect for every scenario. Acknowledging the trade-offs is key to making a sound investment.

Piston Fillers: Precision vs. Maintenance

Piston fillers deliver unmatched accuracy, which reduces product giveaway and ensures a professional look.

However, their mechanical complexity means they require more rigorous cleaning and maintenance, especially when switching between different types of honey.

Container Material: Glass vs. Plastic

Glass jars are non-reactive, preserving honey's pure flavor, and offer a premium, classic appearance. Their downside is that they are heavier, more fragile, and typically more expensive.

Plastic jars and bottles are lightweight, durable, and less prone to breakage during shipping, reducing transport costs. While modern plastics are food-safe, some purists prefer the inert nature of glass for long-term storage.

Automation: Speed vs. Cost

A fully automated, integrated packaging line offers incredible speed and reduces labor costs for high-volume producers.

The initial capital investment for such a system is significant. For smaller or artisanal producers, a semi-automatic or standalone filler often provides the right balance of efficiency and cost-effectiveness.

Making the Right Choice for Your Goal

Your production scale and market focus should guide your final decision.

- If your primary focus is artisanal quality and small-batch production: A semi-automatic piston filler offers the best balance of precision and manageable cost.

- If your primary focus is maximizing output for large-scale distribution: An integrated, fully automatic line with high-speed piston fillers, temperature control, and automated conveying is necessary.

- If your primary focus is product purity and premium branding: Prioritize machines with insulated hoppers and ensure they can expertly handle glass jars to protect flavor and enhance shelf appeal.

Ultimately, investing in a machine designed for honey's specific properties protects your product, your brand, and your bottom line.

Summary Table:

| Key Feature | Purpose | Benefit |

|---|---|---|

| Piston Filler | Precise volume control for thick honey | Consistent fill levels, reduces product giveaway |

| Drip-Prevention Nozzle | Clean cut-off with suck-back device | Minimizes waste, ensures clean packaging |

| Insulated Barrel | Maintains stable honey temperature | Preserves flavor and consistency |

| Versatile Conveying | Handles glass/plastic jars & bottles | Adapts to various container types and sizes |

Maximize Your Honey Packaging Efficiency with HONESTBEE

Struggling with honey's high viscosity and temperature sensitivity? HONESTBEE supplies specialized beekeeping supplies and equipment, including precision piston fillers and integrated packaging systems tailored for commercial apiaries and distributors. Our solutions ensure accurate filling, minimal waste, and preserved product integrity—helping you scale production while maintaining quality.

Contact us today to discuss your packaging needs and explore our wholesale-focused equipment options!

Visual Guide

Related Products

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

- Pneumatic Paste Filling Machine Bottling Packaging Machine Single Nozzle

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

People Also Ask

- How do high-precision honey-filling machines contribute to the competitiveness of honey products? Boost Export Success

- What role do automated filling and packaging machines play in the honey supply chain? Scale Your Retail Distribution

- What is the role of automated honey-filling machines in the post-processing of honey products? Boost Brand & Quality

- How do industrial honey filling machines ensure compliance? Master Quality Control for Global Export

- In what way do automated honey filling and processing machines increase beekeeping value? Boost Plantation ROI

- How does automated honey filling machinery assist in controlling microbial contamination? Optimize Your Honey Purity

- Why is temperature a factor during the filtering and bottling of infused honey? Mastering Flow and Quality Control

- What types of products are best suited for a gravity-fed volumetric filling system? Optimize Your Honey Packaging