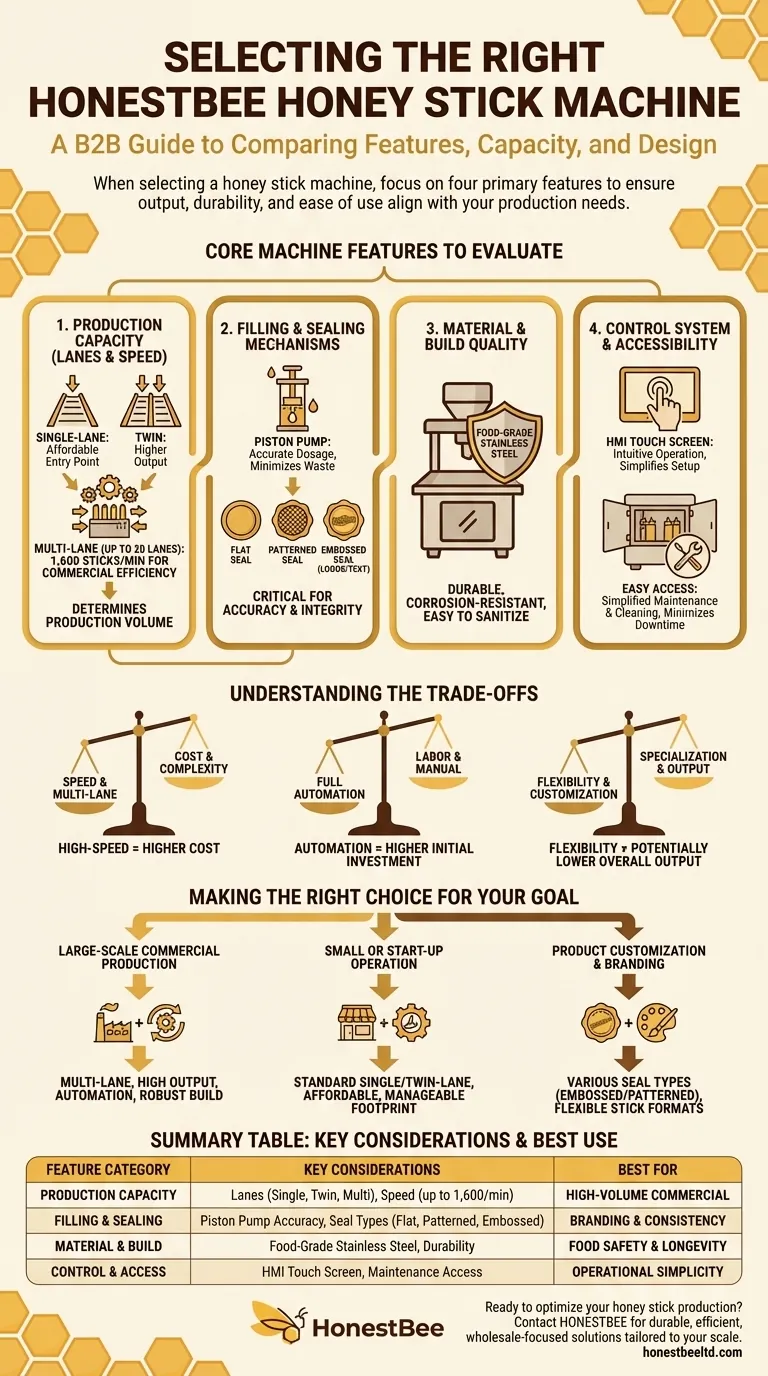

When selecting a honey stick machine, your evaluation should focus on four primary features: the machine's core design and production capacity, its manufacturing materials, the accessibility for maintenance, and the sophistication of its control panel. These factors directly determine the machine's output, durability, and ease of use, ensuring it aligns with your specific production needs.

The most critical decision is not finding the "best" machine, but the right one for your operational scale. The choice ultimately balances the high output and automation of large, multi-lane systems against the affordability and simplicity of smaller machines.

Core Machine Features to Evaluate

Choosing the right honey stick machine requires a detailed comparison of its core functionalities. Your production goals—whether large-scale commercial output or small-batch custom products—will dictate which features are most important.

Production Capacity: Lanes and Speed

The single most significant differentiator is the machine's production volume. This is determined by the number of lanes it operates.

A single-lane machine is a standard, affordable entry point. For higher output, a twin honey stick machine produces two sticks simultaneously.

For large-scale operations, a multi-lane machine is essential. These can have up to 20 lanes and produce as many as 1,600 honey sticks per minute, offering significant efficiency for commercial production lines.

Filling and Sealing Mechanisms

The heart of the machine is its ability to accurately fill and securely seal each stick.

Look for a machine that uses a piston pump for the filling station. This component is critical for ensuring accurate and precise honey dosage in every stick, minimizing waste and ensuring product consistency.

The sealing mechanism determines the final look and integrity of your product. Machines use vertical and horizontal sealing bars and can often be customized to create different seal styles, such as standard flat seals, patterned seals, or even embossed seals with logos or text.

Material and Build Quality

The machine's construction material dictates its lifespan and suitability for food production. Industrial honey stick machines are typically made from high-grade materials to withstand the demands of continuous operation.

Prioritize machines constructed from food-grade stainless steel. This material is not only durable and resistant to corrosion but is also easy to clean and sanitize, which is non-negotiable for food safety compliance.

Control System and Accessibility

Modern machines are operated via a central control panel, often an HMI (Human-Machine Interface) touch screen. A clear, intuitive HMI simplifies setup, operation, and troubleshooting, reducing the need for specialized training.

Pay close attention to the machine's physical design and ease of accessibility. Components like the honey hopper, film rollers, and sealing bars will require regular cleaning and maintenance. A well-designed machine allows for easy access to these parts, minimizing downtime.

Understanding the Machine's Workflow

To appreciate the importance of these features, it's helpful to understand how the machine works. The process is a synchronized sequence of forming, filling, and sealing.

From Film to Finished Stick

The operation begins by loading a roll of packaging film and filling the honey hopper.

The machine then unwinds the film, forms it into a tubular shape using a forming tube, and seals one side vertically. The piston pump then injects a precise amount of honey into the tube.

Finally, the horizontal sealing bars close and seal the stick at both ends, and a cutter separates the finished honey stick, which is then discharged from the machine.

Understanding the Trade-offs

No machine is perfect for every scenario. Your decision will involve balancing competing priorities.

Speed vs. Cost and Complexity

A high-speed, multi-lane machine offers incredible production efficiency, but this comes at a price. These systems have a much higher upfront cost, require more physical space, and often demand more complex maintenance.

A smaller, single-lane machine is far more affordable and easier to manage but cannot match the output of its larger counterparts.

Automation vs. Labor

Fully automatic machines handle every step from film loading to stick discharge, significantly reducing labor costs per unit. However, they carry a higher initial investment.

For smaller or start-up businesses, the lower upfront cost of a less-automated machine may be a more strategic choice, even if it requires more hands-on operator involvement.

Flexibility vs. Specialization

Some machines are built for one purpose: producing a standard 6-7 inch honey stick at maximum speed. Others offer flexibility, such as creating custom seal patterns or accommodating different stick sizes.

This flexibility can be a valuable asset for creating unique products, but it may also lead to more frequent changeover times and slightly lower overall output compared to a dedicated, single-purpose machine.

Making the Right Choice for Your Goal

Ultimately, the best machine is the one that directly supports your business model. Use your primary goal to guide your decision.

- If your primary focus is large-scale commercial production: Prioritize a multi-lane machine with a high output rate (sticks per minute), robust automation, and durable stainless steel construction.

- If your primary focus is a small or start-up operation: A standard single or twin-lane machine offers the best balance of affordability, efficiency, and a manageable operational footprint.

- If your primary focus is product customization and branding: Look for machines that offer options for different seal types (embossed, patterned) and have the flexibility to adjust for varied stick formats.

By aligning the machine's features with your specific production volume and product goals, you can make a confident investment that scales with your business.

Summary Table:

| Feature Category | Key Considerations | Best For |

|---|---|---|

| Production Capacity | Number of lanes (single, twin, multi-lane), output speed (up to 1,600 sticks/min) | High-volume commercial operations |

| Filling & Sealing | Piston pump accuracy, seal types (flat, patterned, embossed) | Branding and product consistency |

| Material & Build | Food-grade stainless steel construction | Durability and food safety compliance |

| Control & Access | HMI touch screen, ease of maintenance access | Operational simplicity and reduced downtime |

Ready to optimize your honey stick production? At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with high-performance honey stick machines tailored to their scale. Whether you need a high-capacity multi-lane system for large-scale output or an affordable single-lane machine for a start-up, our wholesale-focused operations ensure you get durable, efficient equipment that grows with your business. Contact us today for a personalized consultation and discover how our solutions can boost your productivity and profitability!

Visual Guide

Related Products

- Modern Honeycomb Pattern Wooden Honey Dipper for Stirring and Drizzling

- Natural Wood Honey Dipper for Tea Coffee and Desserts

- Premium Heat-Resistant Glass Honey Dipper

- 10L Stainless Steel Electric Honey Press Machine

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

People Also Ask

- Why exclude container weight in honey filling? Master Net Mass Accuracy with Industrial Machinery

- What factors should be considered when selecting a honey packaging machine? Optimize Your Honey Production Line

- How does professional labeling and filling equipment add value to stingless bee products? Maximize Your Market Premium

- How long to let honey sit before bottling? A Guide to Perfectly Clear Honey

- How does the implementation of industrial-grade packaging equipment impact honey market value? Boost Profits & Brand.

- How do automated honey-filling machines contribute to stingless bee honey value? Maximize ROI & Safety Standards

- What are the primary advantages of using automated honey-filling machines? Boost Efficiency and Product Quality

- What is the function of the HMI touch screen in a honey stick machine? Unlock Centralized Control for High-Volume Production