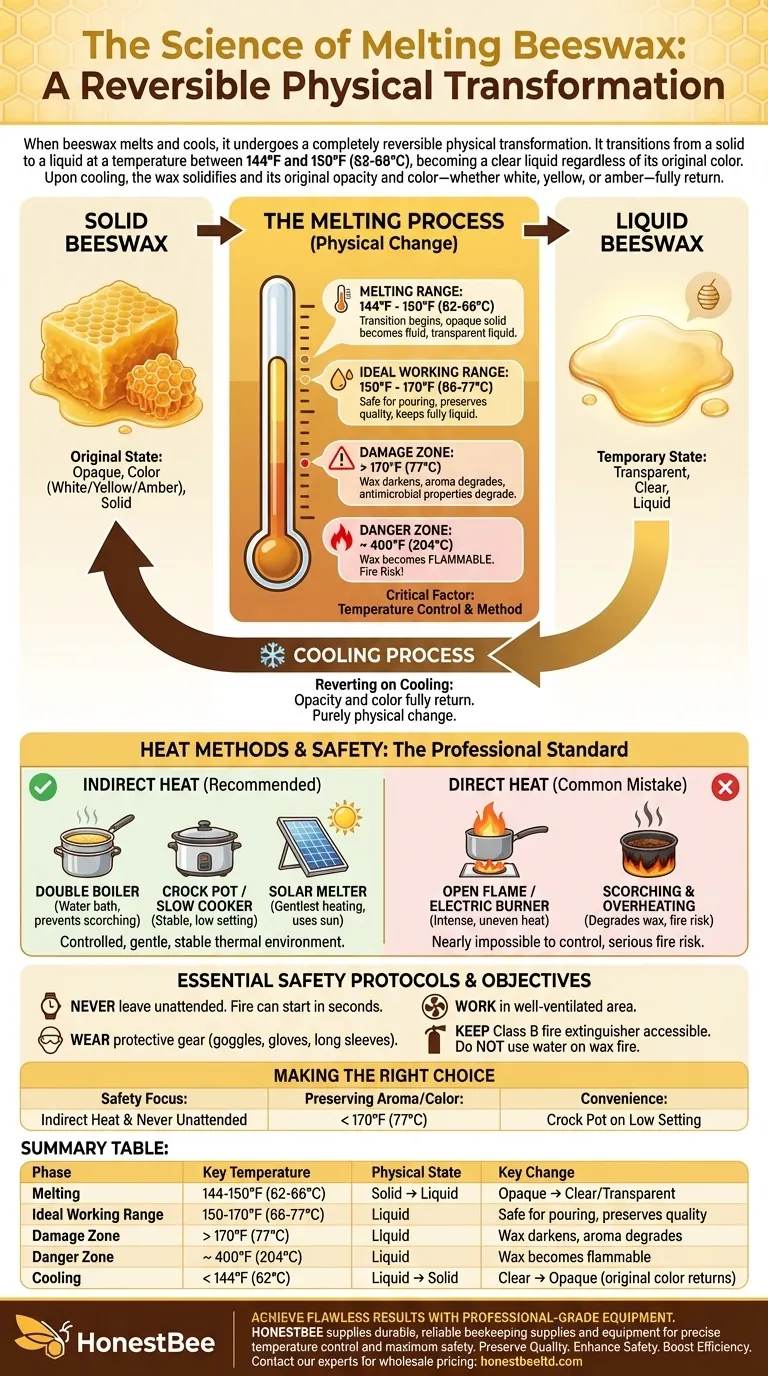

When beeswax melts and cools, it undergoes a completely reversible physical transformation. It transitions from a solid to a liquid at a temperature between 144°F and 150°F (62-66°C), becoming a clear liquid regardless of its original color. Upon cooling, the wax solidifies and its original opacity and color—whether white, yellow, or amber—fully return.

The most critical takeaway is not the physical change itself, but the method used to achieve it. Melting beeswax safely and effectively requires precise, indirect heat to preserve its natural qualities and, most importantly, to prevent a dangerous fire hazard.

The Melting Process: A Step-by-Step Physical Change

Understanding the physical journey of beeswax from solid to liquid and back is straightforward. The process involves predictable changes in state and appearance that are fundamental to working with this natural material.

The Transition to Liquid

Beeswax does not have a single melting point but rather a narrow range. The transition begins around 144°F (62°C) and is typically complete by 150°F (66°C). At this stage, it transforms from an opaque solid into a fluid, transparent liquid.

The Color Transformation

One of the most notable changes is in its appearance. Regardless of its starting color, all beeswax becomes perfectly clear and transparent when fully melted. This is a temporary physical state, not a chemical alteration.

Reverting on Cooling

As the molten beeswax cools and falls below its melting point, it begins to solidify. During this process, its original opacity and color are restored. This demonstrates that the melting and cooling cycle is a purely physical change, not a chemical one.

The Critical Factor: Temperature Control

While melting beeswax is simple in principle, the temperature at which you do it is paramount. Failing to control heat can degrade the quality of the wax and introduce significant safety risks.

The Ideal Melting Range

The goal is to keep the wax just above its melting point. Holding the temperature between 150°F and 170°F (66-77°C) is the ideal working range. This is hot enough to keep it fully liquid for pouring but cool enough to prevent damage.

The "Damage Zone": Above 170°F

Exceeding 170°F (77°C) begins to harm the beeswax. This level of heat can cause the wax to darken permanently and can burn off its subtle, natural honey-like aroma. Furthermore, overheating can degrade its beneficial antimicrobial properties.

The Danger Zone: Flammability

Beeswax is a flammable material. If its temperature reaches approximately 400°F (204°C), it can ignite. This is the single most important reason why precise temperature control and the correct heating method are non-negotiable.

Understanding the Trade-offs: Heat Method and Safety

The primary mistake when melting beeswax is choosing the wrong heating method. Your choice directly impacts both safety and the final quality of your product.

Direct Heat: The Common Mistake

Never melt beeswax by placing a pot directly on an open flame or electric burner. This method provides intense, uneven heat that is nearly impossible to control. It will almost certainly overheat the wax, scorching it and creating a serious fire risk.

Indirect Heat: The Professional Standard

The universally recommended approach is indirect heat. This creates a gentle, stable thermal environment that prevents scorching and overheating.

- Double Boiler: Placing a smaller pot with the wax inside a larger pot of simmering water is the classic method. It physically prevents the wax from exceeding the boiling point of water (212°F or 100°C), keeping it well below the danger zone.

- Crock Pot / Slow Cooker: Using a dedicated slow cooker on its lowest setting is an excellent, stable method for melting wax and keeping it liquid for projects.

- Solar Melter: For purifying raw comb, a solar melter uses the sun's energy for the gentlest heating possible, though it is less practical for indoor craft projects.

Essential Safety Protocols

Because you are working with a hot, flammable liquid, safety must be your priority.

- Never leave melting wax unattended. A fire can start in seconds.

- Wear protective gear, including safety goggles, gloves, and long sleeves, to protect against burns from splashes.

- Work in a well-ventilated area to avoid the buildup of fumes.

- Keep a Class B fire extinguisher accessible. Do not use water to extinguish a wax fire.

Making the Right Choice for Your Goal

Your approach should be dictated by your primary objective, whether it's absolute safety or preserving the wax's most delicate qualities.

- If your primary focus is safety: Always use an indirect heat source like a double boiler and never, under any circumstances, leave melting wax unattended.

- If your primary focus is preserving aroma and color: Use a thermometer to ensure the wax temperature stays below 170°F (77°C) at all times.

- If your primary focus is convenience for a project: Use a dedicated crock pot on a low setting to provide a stable, hands-off heat source.

Ultimately, mastering this process is about using controlled heat to safely unlock the potential of your beeswax.

Summary Table:

| Phase | Key Temperature | Physical State | Key Change |

|---|---|---|---|

| Melting | 144-150°F (62-66°C) | Solid → Liquid | Opaque → Clear/Transparent |

| Ideal Working Range | 150-170°F (66-77°C) | Liquid | Safe for pouring, preserves quality |

| Damage Zone | > 170°F (77°C) | Liquid | Wax darkens, aroma degrades |

| Danger Zone | ~ 400°F (204°C) | Liquid | Wax becomes flammable |

| Cooling | < 144°F (62°C) | Liquid → Solid | Clear → Opaque (original color returns) |

Achieve Flawless Results with Professional-Grade Equipment

Melting beeswax safely and efficiently is critical for commercial apiaries and distributors. HONESTBEE supplies the durable, reliable beekeeping supplies and equipment you need for precise temperature control and maximum safety.

We provide wholesale-focused solutions to help you:

- Preserve Wax Quality: Ensure consistent color and aroma batch after batch.

- Enhance Operational Safety: Mitigate fire risks with equipment designed for controlled heating.

- Boost Efficiency: Scale your rendering and crafting processes with professional tools.

Ready to upgrade your wax processing? Contact our experts today to discuss wholesale pricing and find the perfect equipment for your operation.

Visual Guide

Related Products

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Colorful Silicone Beeswax Foundation Mold Mould for Beekeeping

- Professional Frame Preparation: The HONESTBEE Electric Wire Embedder

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

People Also Ask

- How long does it take for the Solar Wax Melter to warm up? Get Melting in 30 Minutes

- What can be done with leftover wax after honey extraction? Turn Cappings into Valuable Products

- What equipment is recommended for a makeshift beeswax double boiler? Safe DIY Wax Melting Guide

- Why is precision temperature-controlled melting equipment required in beeswax purification? Protect Wax Quality

- What is the recommended procedure for floating wax to extract honey? A Low-Cost, Gravity-Based Method

- What methods are used to melt and clarify beeswax cappings? Commercial Techniques for High-Quality Refinement

- What role does refining equipment play in beeswax production? High-Purity Solutions for Cera Flava and Cera Alba

- How do specialized wax melting devices contribute to the resource utilization of an apiary? Maximize Beeswax Value