At a glance, honey fillers are most directly recommended for the honey production industry and the pharmaceutical sector. These machines are purpose-built to handle the unique challenges of high-viscosity liquids, ensuring accurate dosing and minimal product degradation during the packaging process.

The term "honey filler" is something of a misnomer. These machines are more accurately described as viscous liquid fillers, engineered for any product that shares honey's challenging properties: thickness, stickiness, and sensitivity to aeration.

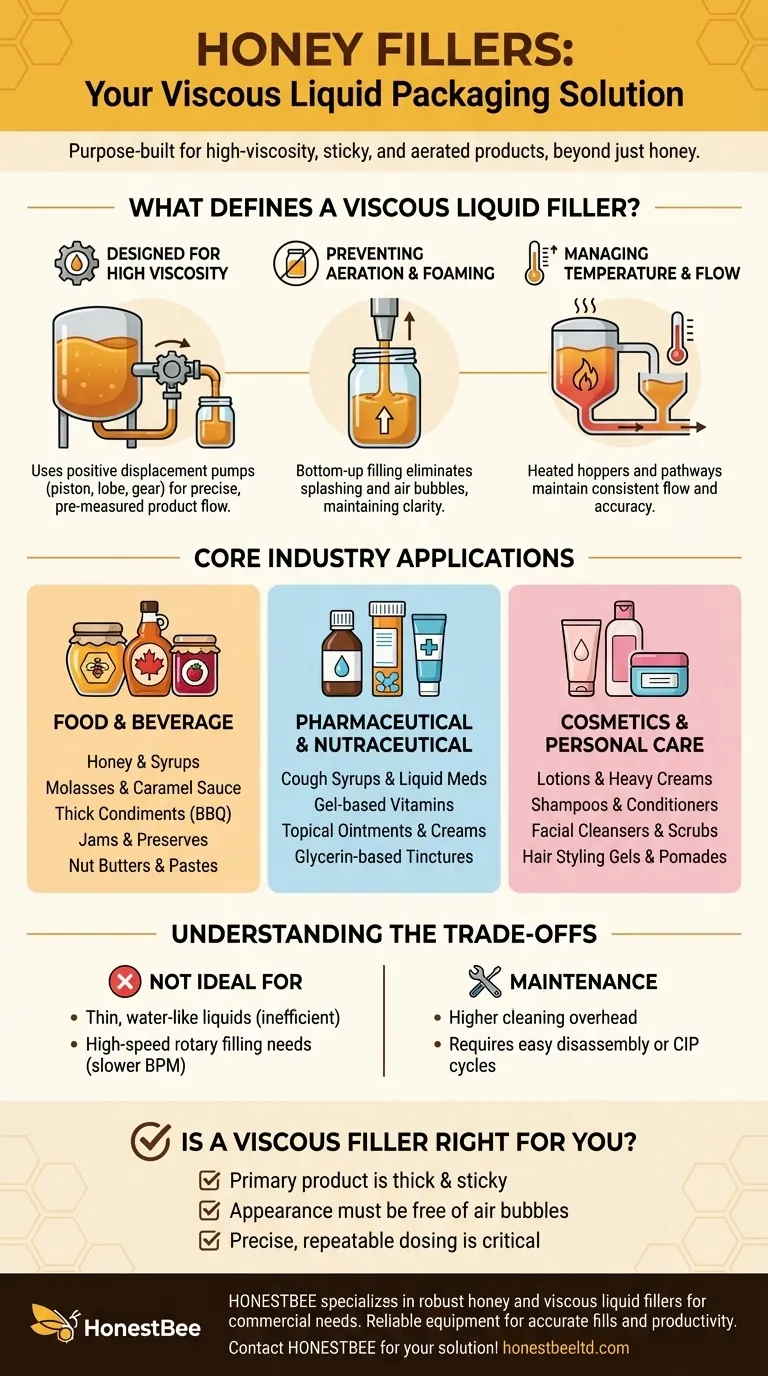

What Defines a Viscous Liquid Filler?

To understand the applications, you must first understand the core technical problems these machines are designed to solve. They are not defined by the product name, but by the physics of the product they handle.

Designed for High Viscosity

The primary challenge is moving a thick, slow-flowing liquid from a bulk tank into a small container accurately and efficiently.

These fillers use positive displacement pumps, such as piston, lobe, or gear pumps. Unlike simpler gravity fillers, these pumps force a precise, pre-measured volume of product through the system with each cycle, regardless of viscosity changes.

Preventing Aeration and Foaming

Introducing air bubbles into a thick product like honey or a gel ruins its visual clarity, can affect its shelf life, and leads to inaccurate fill levels.

To prevent this, viscous fillers almost always employ bottom-up filling. The dispensing nozzle is lowered to the bottom of the container and slowly retracts as the product is dispensed, keeping the nozzle below the liquid's surface and eliminating splashing or foaming.

Managing Temperature and Flow

Honey and many other viscous products change their flow characteristics dramatically with temperature.

Many viscous filling systems incorporate heated hoppers, tanks, and product pathways. This maintains the product at an optimal, consistent temperature, ensuring it flows smoothly and can be measured accurately throughout a production run.

Core Industry Applications

While the name points to honey, the technology is applicable across any industry dealing with thick liquids, gels, or creams.

The Food & Beverage Industry

This is the most obvious application, but it extends far beyond just honey. The principles of handling viscosity and preventing aeration are critical for many products.

Examples include:

- Syrups (maple, agave, corn)

- Molasses and caramel sauce

- Thick condiments (BBQ sauce, ketchup)

- Jams, jellies, and fruit preserves

- Nut butters and pastes

The Pharmaceutical & Nutraceutical Sector

Precision and sanitation are paramount in this industry. Viscous fillers provide the accurate dosing required for medical and health products.

These machines are used for:

- Cough syrups and liquid medicines

- Gel-based vitamins and supplements

- Topical ointments, creams, and medicinal gels

- Glycerin-based tinctures

The Cosmetics & Personal Care Industry

Product appearance and consistency are key selling points in cosmetics. The ability to fill thick creams and gels without air bubbles is essential.

Common uses include filling:

- Lotions and heavy creams

- Shampoos and hair conditioners

- Facial cleansers and scrubs

- Hair styling gels and pomades

Understanding the Trade-offs

No machine is perfect for every task. Viscous liquid fillers are highly specialized and come with specific limitations.

Not for Thin, Water-Like Liquids

Using a piston filler for a product like water, juice, or a light oil is inefficient. The robust pump mechanism is overkill, and simpler, faster technologies like gravity fillers or overflow fillers are far better suited for low-viscosity products.

Slower Speeds Than Other Filler Types

The methodical, controlled action of a positive displacement pump and a bottom-up fill cycle takes time. Consequently, viscous fillers generally have a lower bottles-per-minute (BPM) rate compared to high-speed rotary fillers used for beverages.

Higher Cleaning & Maintenance Overhead

Thick, sticky products are inherently more difficult to clean from a machine. Systems must be designed for easy disassembly, or they must incorporate automated Clean-In-Place (CIP) cycles, which adds to the machine's complexity and cost.

How to Determine if a Viscous Filler is Right for You

Focus on your product's properties, not just your industry category, to make the correct choice.

- If your primary product is thick, sticky, or flows slowly: A viscous liquid filler (often called a honey filler) is engineered specifically for this challenge.

- If your product's appearance is critical and must be free of air bubbles: The bottom-up fill mechanism common in these machines is essential for maintaining quality.

- If your product requires precise, repeatable dosing (common in pharmaceuticals or high-value foods): The positive displacement pumps used in these systems provide the necessary accuracy.

- If your primary product is thin and free-flowing (like water, juice, or light oil): You should explore other technologies like gravity or overflow fillers for better speed and cost-effectiveness.

Ultimately, choosing the right filling machine depends not on an industry label, but on the physical properties of your product itself.

Summary Table:

| Industry | Key Applications | Key Filler Benefits |

|---|---|---|

| Food & Beverage | Honey, syrups, jams, nut butters, sauces | Precise dosing, handles stickiness, maintains product quality |

| Pharmaceutical & Nutraceutical | Cough syrups, ointments, gel supplements | Accurate volume control, sanitary design, critical for dosing |

| Cosmetics & Personal Care | Lotions, creams, shampoos, gels | Prevents aeration, preserves appearance, consistent fills |

Struggling to package your thick, viscous products efficiently?

HONESTBEE specializes in supplying robust honey and viscous liquid fillers designed for the demands of commercial apiaries and beekeeping equipment distributors. Our wholesale-focused operations provide you with reliable equipment that ensures accurate fills, prevents product degradation, and boosts your packaging line's productivity.

Contact HONESTBEE today to find the perfect filling solution for your high-viscosity products!

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Commercial Rotary Honey Filling Machine for Production

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

People Also Ask

- How do industrial honey-filling machines enhance the honey production value chain? Scale Your Apiary Business Efficiency

- Why is the motor an important factor when selecting a filling machine? Boost Efficiency and Simplify Production

- How does a semi-automatic filling machine operate? Boost Your Production Consistency

- How do high-precision honey filling and packaging machines contribute to the commercial value? Boost ROI & Quality

- What are the key advantages of using a honey stick machine in production? Optimize Your Beekeeping Business

- What types of honey filling machines are available? Find the Perfect System for Your Apiary

- How do automated honey filling machines and processing equipment contribute to market competitiveness? From Bulk to Brand

- Why are industrial-grade honey filling machines necessary? Scale Your Apiary with Professional Processing Efficiency