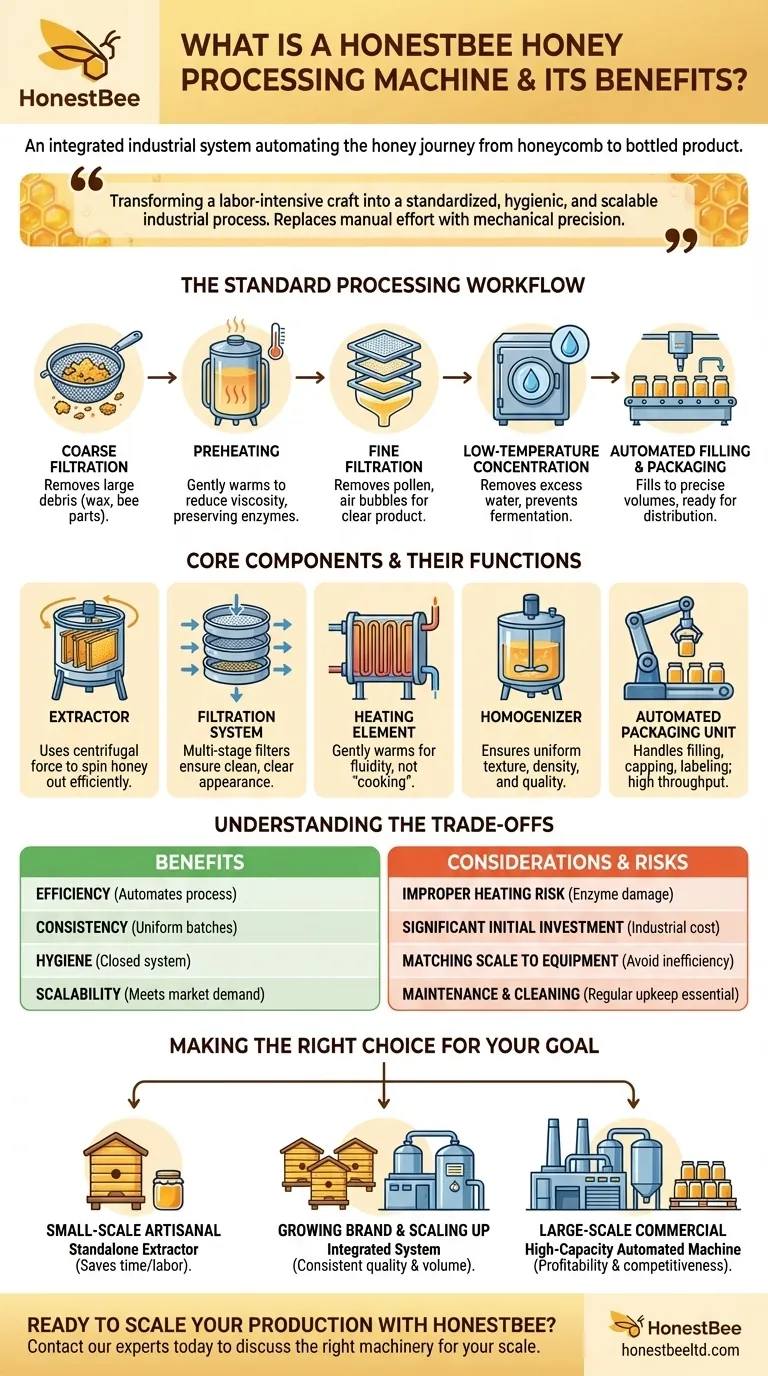

In essence, a honey processing machine is an integrated system of industrial equipment designed to extract, filter, homogenize, and bottle honey with minimal human intervention. It automates the entire journey from raw honeycomb to a finished, market-ready product, significantly increasing the efficiency and consistency of honey production for beekeepers and commercial operators.

A honey processing machine is not just about speed; it's about transforming a labor-intensive craft into a standardized, hygienic, and scalable industrial process. It replaces manual effort with mechanical precision to ensure every jar of honey meets a consistent quality standard.

How a Honey Processing Machine Transforms Production

To understand the benefits, you must first understand the mechanics. A full processing line transforms raw honeycombs into a finished product through a specific, automated sequence.

The Standard Processing Workflow

The machine guides honey through a multi-stage journey to refine it for packaging. The typical workflow includes:

- Coarse Filtration: Raw honey is first passed through a preliminary filter to remove large debris like wax chunks, bee parts, and other impurities.

- Preheating: The honey is gently warmed. This step is crucial as it reduces the honey's viscosity (makes it more fluid) without degrading its natural quality.

- Fine Filtration: Now more fluid, the honey is passed through a finer filter to remove smaller particles, such as pollen and air bubbles, resulting in a clear final product.

- Low-Temperature Concentration: Some systems may use a vacuum to remove excess water content from the honey, standardizing its consistency and preventing fermentation.

- Filling: Finally, an automated packaging unit fills jars or other containers to precise volumes, preparing the honey for sealing and distribution.

Core Components and Their Functions

Each part of the machine has a distinct and vital role in ensuring efficiency and quality.

The Extractor This component uses centrifugal force to spin honey out of the uncapped honeycombs. This is far more efficient than traditional crushing or draining methods.

The Filtration System A multi-stage system of sieves and filters is responsible for removing all physical impurities. This ensures the honey has a clean, clear appearance that consumers expect.

The Heating Element Often a jacketed tank or heat exchanger, this component gently warms the honey. The goal is simply to improve fluidity for easier filtering and pumping, not to "cook" it.

The Homogenizer This equipment ensures that the entire batch of honey has a uniform texture, density, and quality. It prevents crystallization nucleation and guarantees that the first jar is identical to the last.

The Automated Packaging Unit This final stage automates the bottling process. It handles the filling, capping, and sometimes labeling of containers, drastically reducing manual labor and increasing throughput.

Understanding the Trade-offs

While the benefits are significant, a professional must also consider the potential downsides and operational realities.

The Risk of Improper Heating

The most critical trade-off involves heat. While gentle warming is necessary for processing, overheating honey can destroy its delicate enzymes, darken its color, and alter its flavor profile. High-quality machines are designed for precise temperature control to mitigate this risk.

Significant Initial Investment

These are industrial machines with a corresponding price tag. The initial capital outlay can be substantial, especially for fully integrated systems. The return on investment depends entirely on the scale of your operation.

Matching Scale to Equipment

A machine designed for a multi-ton commercial operation is entirely unsuitable for a beekeeper with a few dozen hives. It's crucial to select equipment that matches your current and projected production volume to avoid unnecessary expense and operational inefficiency.

Maintenance and Cleaning

Though designed for low maintenance and easy cleaning, these machines are not "set it and forget it." Regular cleaning is essential for hygiene, and periodic maintenance is required to ensure all mechanical components are functioning correctly.

Making the Right Choice for Your Goal

The decision to invest in a honey processing machine hinges on your specific production goals and scale.

- If your primary focus is small-scale, artisanal production: A full processing line is likely overkill, but a standalone mechanical extractor can save significant time and labor.

- If your primary focus is growing a brand and scaling up: An integrated system is the key to achieving the consistent quality, hygiene, and volume needed to expand into larger markets.

- If your primary focus is large-scale commercial operation: A high-capacity, fully automated processing machine is a non-negotiable asset for maintaining profitability and market competitiveness.

Ultimately, adopting this technology is a strategic decision that empowers you to control product quality and production efficiency at scale.

Summary Table:

| Key Aspect | Benefit |

|---|---|

| Efficiency | Automates the entire process from comb to jar, drastically reducing manual labor. |

| Consistency | Ensures uniform texture, clarity, and quality in every batch of honey. |

| Hygiene | Provides a controlled, closed system that minimizes contamination risks. |

| Scalability | Enables beekeepers to increase production volume to meet market demands. |

Ready to scale your honey production with industrial-grade efficiency?

As HONESTBEE, we specialize in supplying robust honey processing equipment and beekeeping supplies to commercial apiaries and distributors. Our solutions are designed to help you achieve consistent quality, maximize throughput, and grow your business.

Contact our experts today to discuss the right machinery for your operational scale and goals.

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- 24 Frame Honey Extractor Commercial Radial Honey Frame Extraction Machine

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- What factors should be considered when choosing between an electric and manual honey extractor?

- What to do with wet frames after extracting honey? Let Your Bees Clean Them for Best Results

- What should a beekeeper do after extracting honey from supers? A Guide to Harvest Management

- What are the characteristics of motors used in honey extractors? Ensure Efficient, Damage-Free Honey Harvesting

- How to get honey out of a frame? Choose Between Crush & Strain or Centrifugal Extraction